High-wear-resistant super-amphiphobic catalyst coating and preparation method and application thereof

A catalyst and catalyst carrier technology, which can be used in catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., can solve the problems of unsustainable oleophobic and hydrophobic properties, poor wear resistance of coatings, etc., and achieve good industrial application prospects. Good capacitance and the effect of reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present embodiment provides a kind of highly wear-resistant super amphiphobic catalyst coating, and this coating is made through the following steps:

[0038] (1) Obtain silica microspheres, modify them with tridecafluorooctyltrimethoxysilane to be oleophobic and hydrophobic, wash and dry them for later use.

[0039] (2) Use aluminum chloride to hydrolyze under acidic conditions to prepare aluminum hydroxide gel, place the modified silica microspheres obtained in step (1) in the hydrolysis reaction system, keep stirring, the hydrolysis temperature is 40°C, and the hydrolysis The time is 30 minutes, and then the excess aluminum hydroxide gel is removed by filtration, and the silica microspheres coated with aluminum hydroxide gel are placed in a muffle furnace for roasting at a temperature of 220°C for 3 hours, and then cooled for later use.

[0040] (3) Add 10ml of tetraethyl orthosilicate into 100ml of absolute ethanol, stir for 10min, then add 3g of alumina-coated ...

Embodiment 2

[0047] The highly wear-resistant superamphiphobic catalyst coating provided in this embodiment is prepared through the following steps:

[0048] (1) Obtain silica microspheres, and use fluorine modifier to carry out oleophobic and hydrophobic modification on them, wash and dry them for later use.

[0049] (2) To prepare a saturated sodium chloride solution, add the silicon dioxide microspheres obtained in step (1) into a saturated sodium chloride saturated solution, heat and stir until the silicon dioxide is evenly coated with a layer of sodium chloride, and take out ,spare.

[0050] (3) Add 15ml of tetrabutyl titanate into 100ml of absolute ethanol, ultrasonicate for 30min, then add 4g of silica microspheres coated with sodium chloride at the same time under ultrasonic operation, stir for 10min, filter, and place in air at room temperature Naturally air-dried in the atmosphere, then placed in a muffle furnace for 2 h at 500° C., washed three times with deionized water and on...

Embodiment 3

[0056] The highly wear-resistant superamphiphobic catalyst coating provided in this embodiment is prepared through the following steps:

[0057] (1) Obtain silica microspheres, and use fluorine modifier to carry out oleophobic and hydrophobic modification on them, wash and dry them for later use.

[0058] (2) To prepare a saturated sodium chloride solution, add the silicon dioxide microspheres obtained in step (1) into a saturated sodium chloride saturated solution, heat and stir until the silicon dioxide is evenly coated with a layer of sodium chloride, and take out ,spare.

[0059] (3) Add 10ml of tetraethyl orthosilicate to 100ml of absolute ethanol, stir for 10min, then add 4g of silica microspheres coated with sodium chloride and ammonia water at the same time under ultrasonic operation, and react at 70°C for 10h , washed three times by centrifugation with deionized water, and vacuum-dried to obtain micro-nano composite microspheres 2.

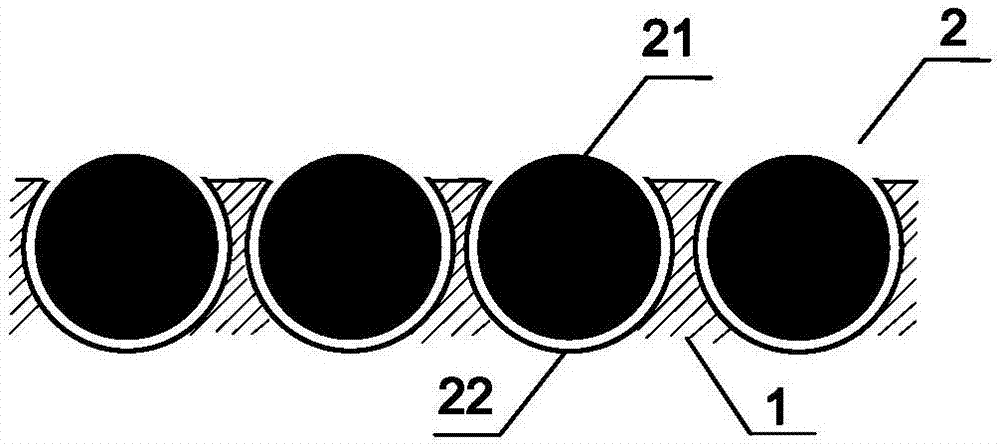

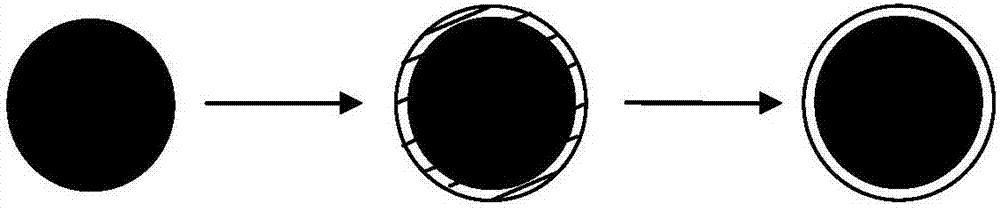

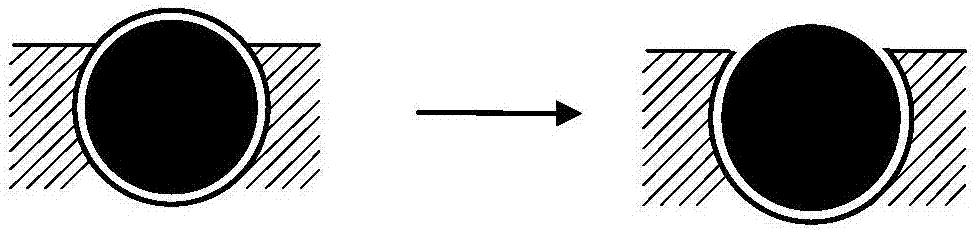

[0060] figure 2 Shown is a sch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com