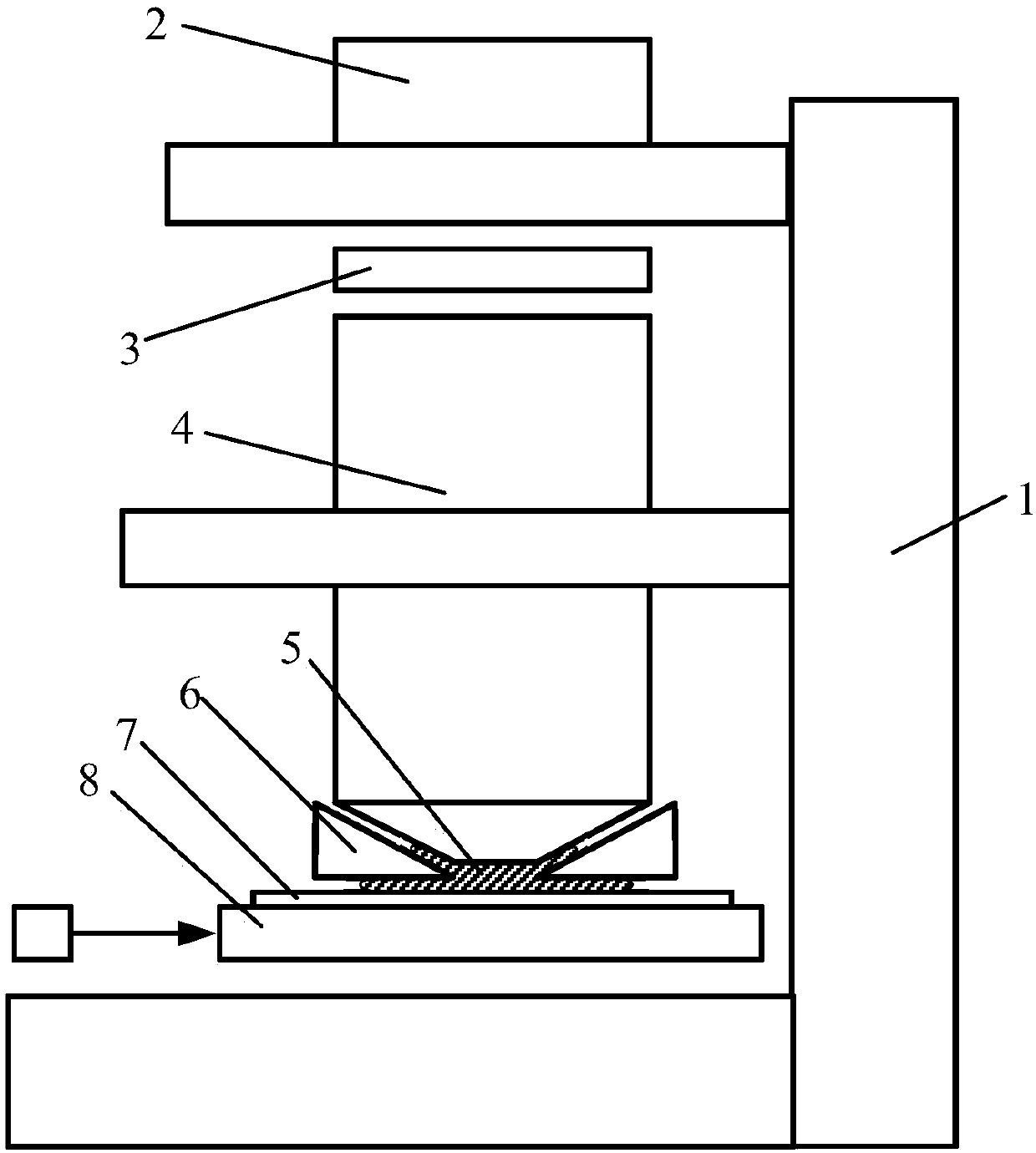

Fluid extracting-discharging apparatus and immersion type photoetching machine

A technology of fluid and flow guide mechanism, applied in the field of photolithography, can solve problems such as unstable immersion flow field pressure, unstable pipeline pressure, and affecting exposure quality, and achieve the effect of simple structure, stable pressure, and improved exposure quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

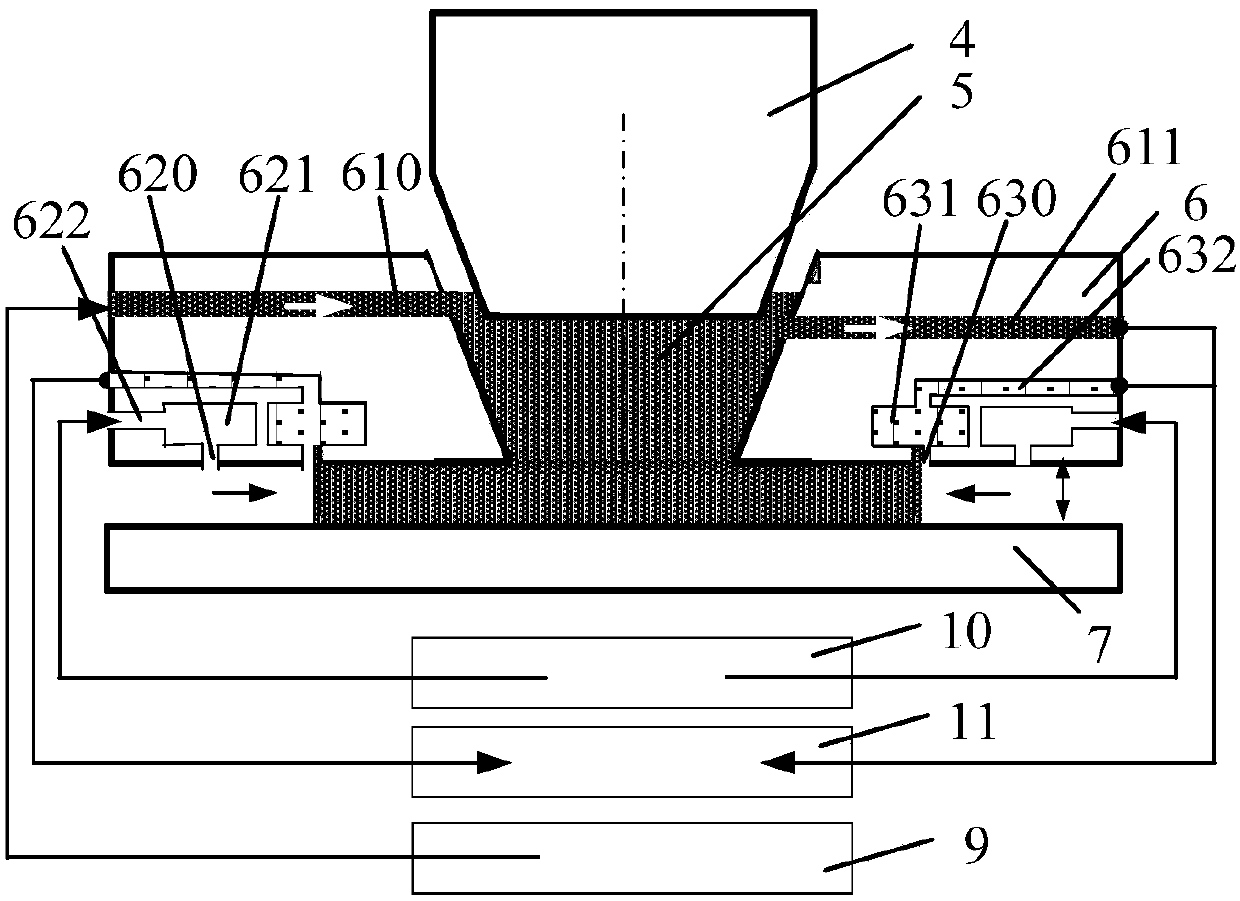

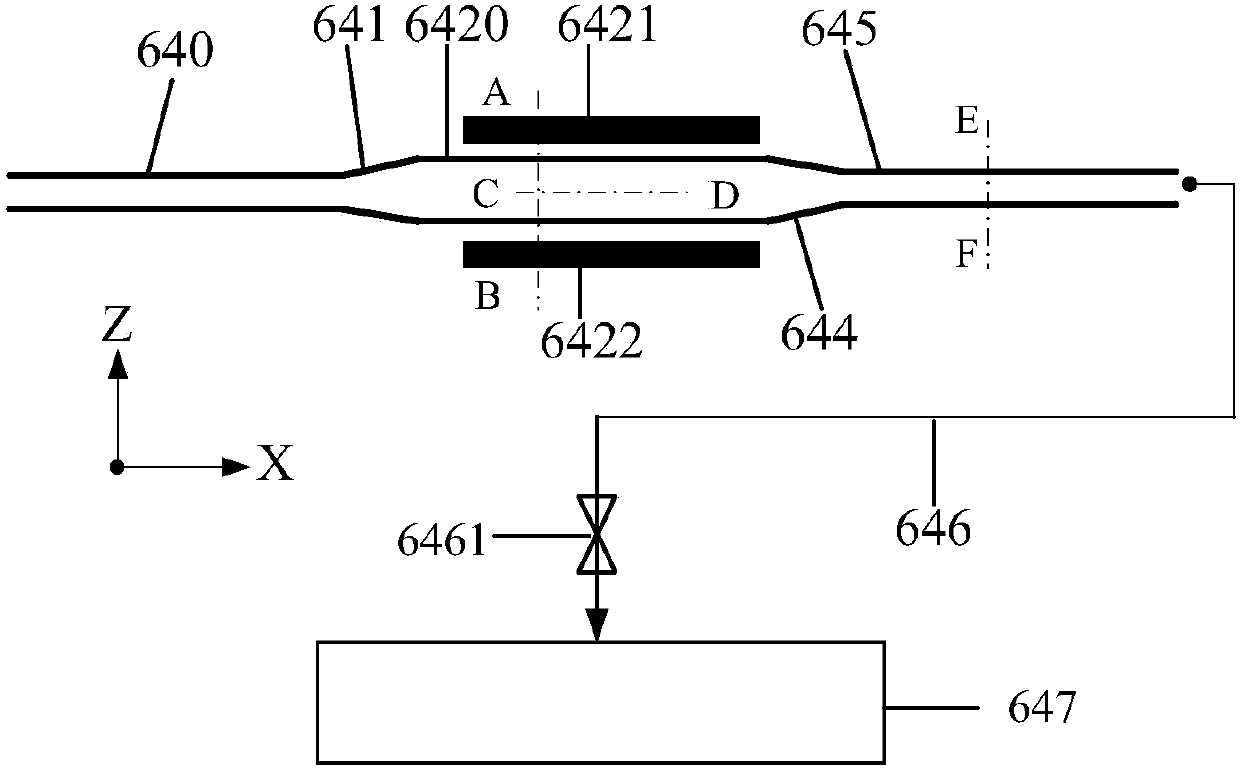

[0046] see image 3 with Figure 4 , a fluid pumping device, connected to the immersion head 6 and the gas-liquid recovery device 647 for pumping the gas-liquid two-phase flow at the edge of the immersion liquid flow field in the immersion head 6 to the gas-liquid recovery device 647, the The fluid pumping device includes a first pumping tube 640, a first flow guide mechanism 641, an atomization chamber, a second flow guide mechanism 644, a second pumping tube 645, and a third pumping tube 646 connected in sequence. A suction pipe 640 is connected to the immersion head 6, and the gas-liquid two-phase flow at the edge of the immersion liquid flow field is pumped out of the immersion head 6 through the gas-liquid suction pipe and enters the first suction pipe 640 , thereby entering the fluid pumping device.

[0047] see Figure 5 with Image 6 , image 3 The cross-sectional structures at positions A-B and C-D, the atomization chamber includes a chamber 6420 with left and ri...

Embodiment 2

[0053] see Figure 8 The difference between embodiment 2 and embodiment 1 is that two sets of first flow guide rib arrays 6423 are arranged in the atomization chamber, and the first flow guide rib arrays 6423 divide the gas-liquid two-phase flow and separate For isotropic processing, there is a certain gap between the two groups of the first diversion rib arrays 6423, and they are not connected to each other as a whole. There are gaps between the third guide rib arrays 6442, and they are not connected to each other as a whole.

[0054] The fluid pumping device also includes a surfactant injection device and an air supply device. The surfactant injection device includes a surfactant supply pipeline 6481, a surfactant injection device 6482 and a surfactant flow control valve 6483. One end of the surfactant supply pipeline 6481 is connected to the surfactant injection device 6482, and the other end is connected to the atomization chamber, and the mouth of the surfactant supply p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com