Natural moringa organic calcium and preparation method thereof

A technology of organic calcium and moringa, applied in the field of calcium preparations, can solve problems such as insufficient application, inability to exert effects, low ion calcium content, etc., to avoid the growth of miscellaneous bacteria, high solubility, high nutrition and supplementation. The effect of calcium value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

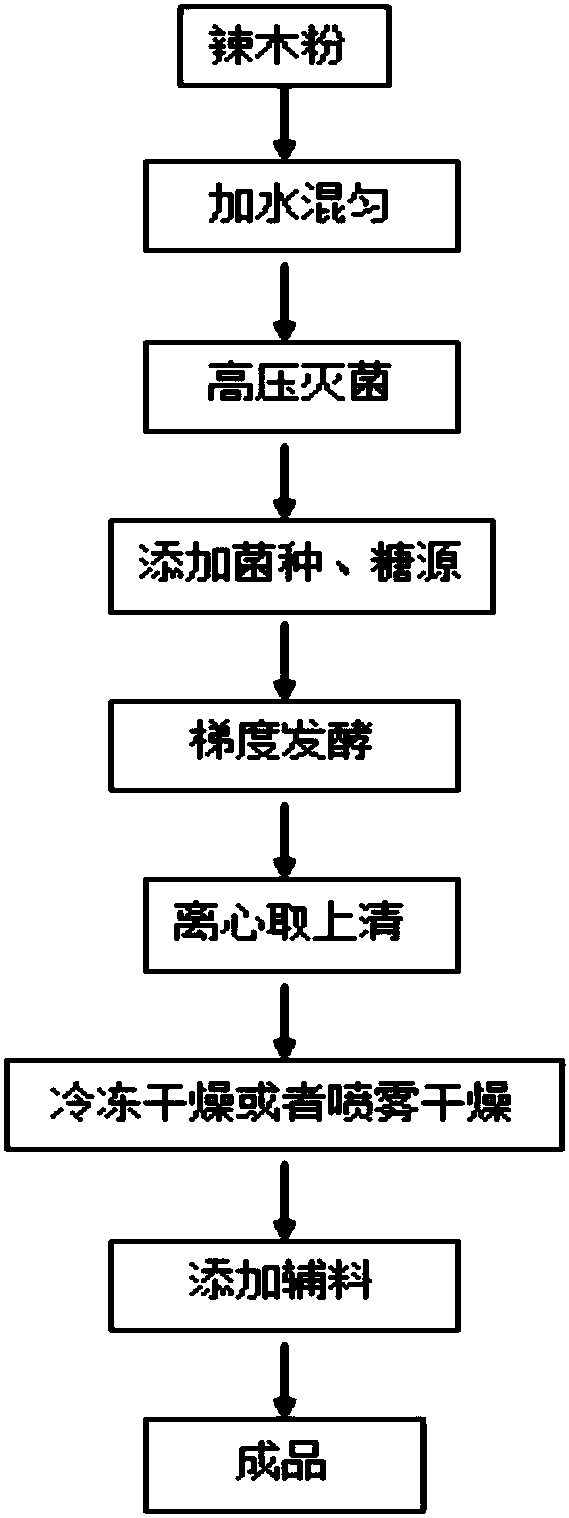

Method used

Image

Examples

Embodiment 1

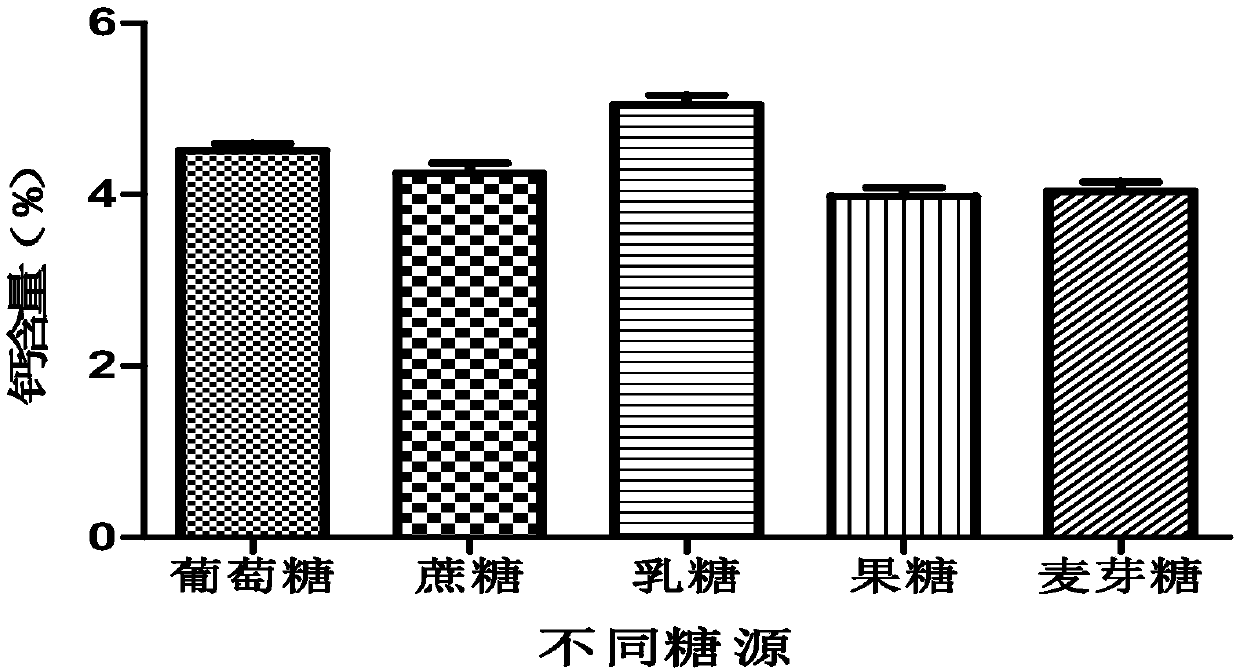

[0036] Embodiment 1 adopts Lactobacillus acidophilus, Lactobacillus johnsonii, Lactobacillus reuteri and Saccharomyces cerevisiae I to ferment

[0037] (1) Drying: select tender fresh leaves of Moringa oleifera at 105-110°C for 10-15 minutes, then dry at 65°C.

[0038] (2) Grinding: pulverize the dried Moringa oleifera leaves with a grinder or a flour mill, and pass through a 60-mesh sieve for subsequent use.

[0039] (3) Add water and mix well: Add warm water (75-85°C) according to the ratio of Moringa powder: water 1: (15-20) and stir evenly.

[0040] (4) Autoclaving: put the Moringa oleifera aqueous solution into a suitable glass or stainless steel vessel and then transfer it to an autoclave for sterilization. Sterilization conditions are 121°C for 15-20 minutes. Note that the sterilizer is allowed to be opened after the temperature of the sterilizer drops to 50°C, so as to avoid the phenomenon of the spray bottle caused by the deposition of Moringa powder and the rapid de...

Embodiment 2

[0050] Embodiment 2 continuous anaerobic fermentation

[0051]Change the fermentation method in Example 1 from staged fermentation to 37°C fermentation for 72 hours under anaerobic conditions, and end the fermentation when the pH is 3.75 to 3.85. Other conditions remain unchanged, and the total solids and calcium content of the final product are respectively stage 89.1% and 83.3% of the formula fermentation content, yield and product quality reduce; The fermentation mode among the embodiment 1 is changed into 37 ℃ of fermentation 72h under the aerobic condition by staged fermentation, pH is difficult to reduce, and the whole fermentation process pH value Decreased from 5.67 to 5.11, while the taste and flavor of the product were significantly reduced, and an unpleasant stench appeared. The yield and calcium content were respectively 82.33% and 93.78% of those of stage fermentation. When finishing fermentation, other conditions are constant, and the final solids total amount of...

Embodiment 3

[0052] Embodiment 3 changes strain and prepares organic calcium

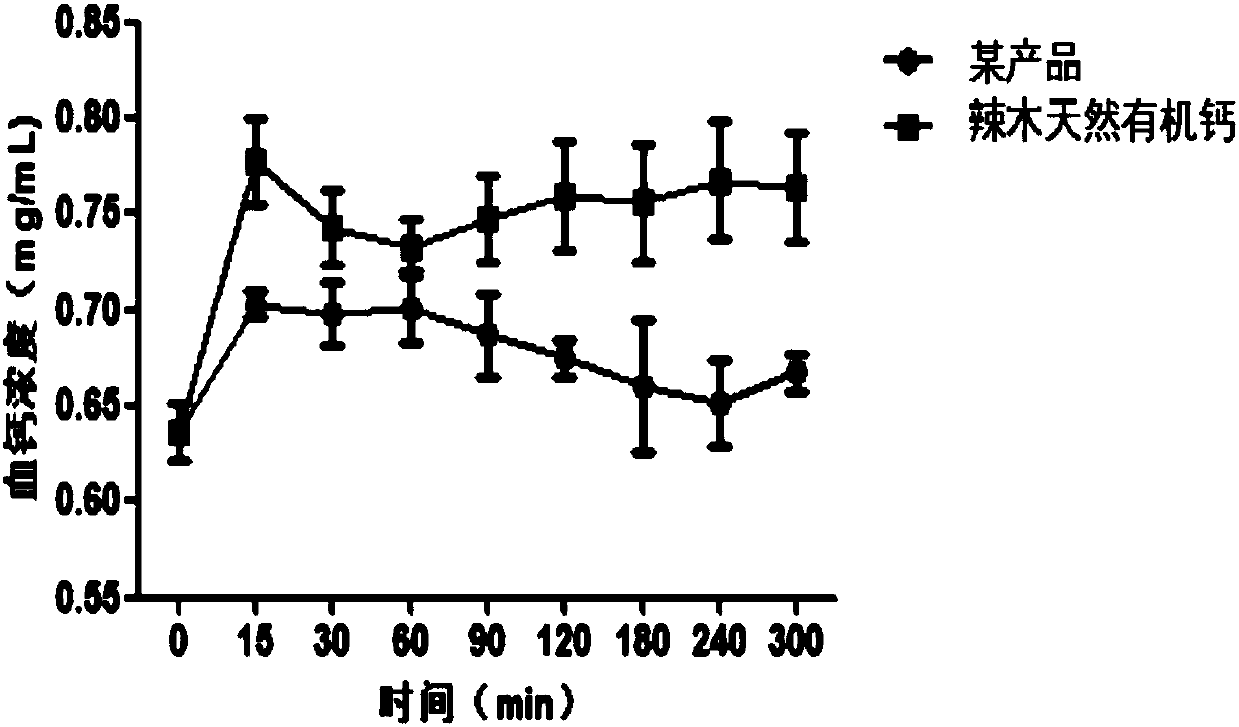

[0053] The natural organic calcium fermentation liquid of Moringa oleifera prepared by using these four strains and staged fermentation can reach (4972±116) mg / 100g after freeze-drying or spray-drying. 2. Lactobacillus bulgaricus, Lactobacillus thermophiles, Lactococcus bulgaricus, Lactobacillus casei, Lactobacillus acidophilus, Lactobacillus johnsonii, Lactobacillus reuteri, Bifidobacterium longum, Lactobacillus fermentum, Lactobacillus rhamnosus After acclimatization by the same method, inoculate the same amount of strains and ferment at the optimum temperature (30°C for yeast, 37°C for lactic acid bacteria) under the same fermentation conditions, and the supernatant after centrifugation of the fermentation broth was spray-dried to determine its calcium content. (4171±97), (3822±221), (3211±103), (3166±217), (3301±117), (3455±88), (3699±106), (3819±179), ( 3779±211), (3008±164), (3471±119), (3551±103) mg / 100g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com