Ionic polymer derivative carbon material used as lithium-sulfur battery positive electrode material

An ionic polymer, lithium-sulfur battery technology, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc. The effect of accelerating ion and electron transfer, improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

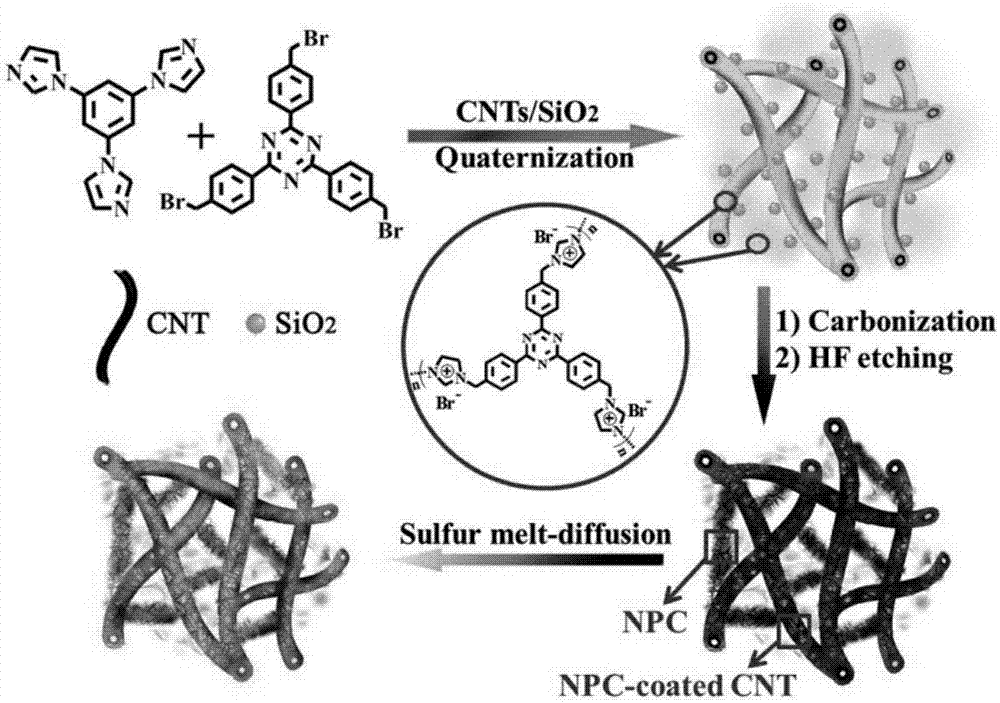

[0033] 1. Preparation of CNT / NPC-300-S cathode material

[0034] At room temperature, 150 mg of carbon nanotubes and 938 mg of silica nanoparticles were dispersed in N,N-dimethylformamide, and after ultrasonication for 2 hours, 300 mg of tribenzimidazole and the same equivalent of triazine benzyl bromide were added , After continuing to stir for 1h, it was heated to 80°C for 48h. After suction filtration, washing and drying, the precursor of CNT / NPC-300 polymer composite material containing silica was obtained, and the polymer was heated to 800° C. for carbonization in nitrogen atmosphere for 3 hours. Cool to room temperature, wash with hydrofluoric acid solution, centrifuge, wash, and dry to obtain CNT / NPC-300. The CNT / NPC-300-S polymer, namely CNT / NPC-300-57S, was prepared by the melt-diffusion method.

[0035] The preparation route of CNT / NPC-300 polymer and CNT / NPC-300-S in this embodiment is as attached figure 1 shown.

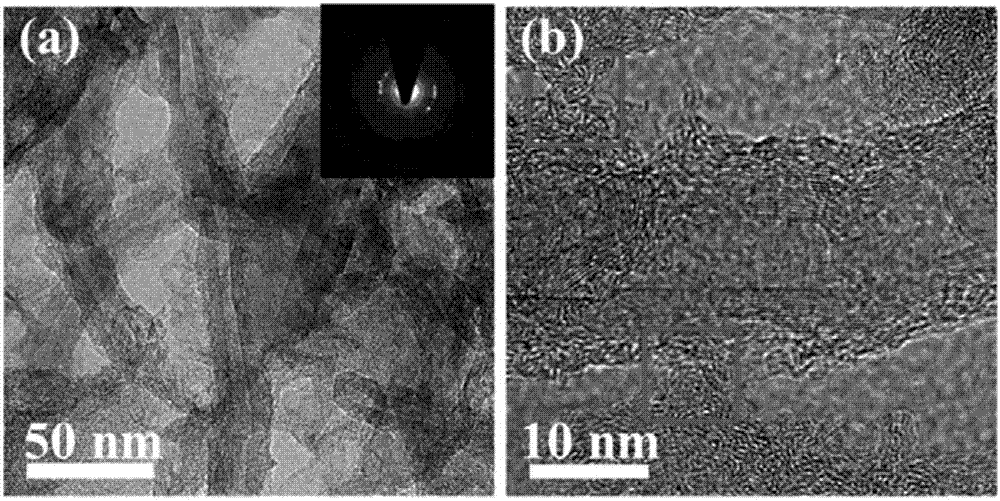

[0036] The transmission electron microscope ima...

Embodiment 2

[0040] 1. Preparation of N, S co-doped material CNT / NPC-TFSI-55S cathode material

[0041]At room temperature, disperse 300mg of carbon nanotubes and 1560mg of silica nanoparticles in N,N-dimethylformamide, and after ultrasonication for 2 hours, add 500mg of tribenzimidazole and the same equivalent of triazine benzyl bromide , After continuing to stir for 1h, it was heated to 110°C for 24h. After suction filtration, washing and drying, the precursor of the polymer composite material containing silicon dioxide is obtained. Disperse the precursor in deionized water, add lithium bistrifluoromethanesulfonate imide for anion exchange, stir for 24 hours, centrifuge, wash, and vacuum dry. After carbonization at 1000°C for 1 h in a nitrogen atmosphere, it was etched with hydrofluoric acid to obtain the N, S double-doped material CNT / NPC-TFSI. The CNT / NPC-TFSI-S composite material was prepared by melt-diffusion method to obtain CNT / NPC-TFSI-55S.

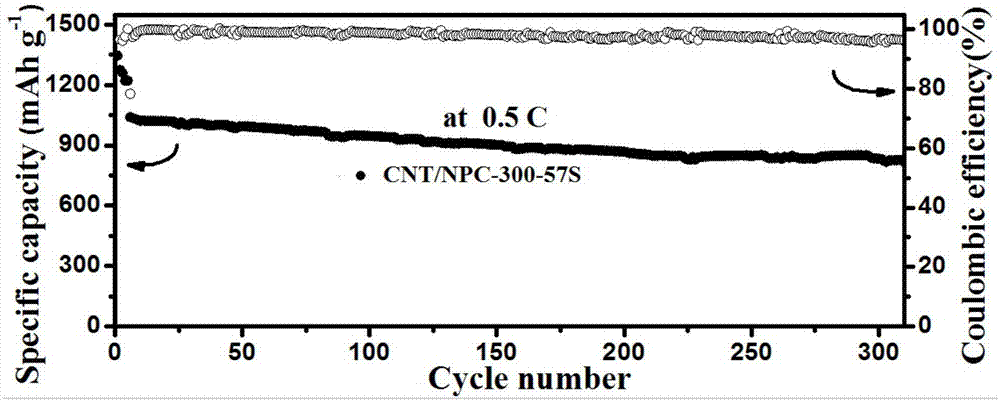

[0042] 2. Electrochemical performan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com