Construction structural adhesive and preparation method thereof

A building structural adhesive and modification technology, applied in the direction of adhesives, epoxy resin adhesives, carboxyl rubber adhesives, etc., can solve the problem of poor moisture and heat aging resistance of building structural adhesives, difficult to meet the requirements of safety and reliability, short service life, etc. problems, to achieve the effect of increasing rigidity, preventing water vapor from entering, and improving moisture and heat aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

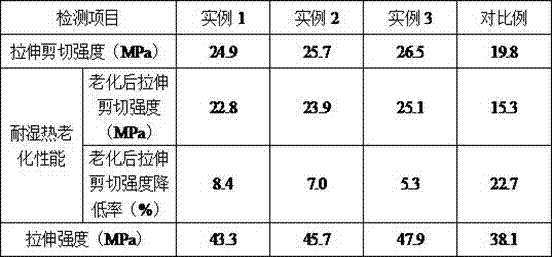

Examples

example 1

[0020] Take 10g of 2,7-dihydroxynaphthalene and 100mL of ethanol solution with a mass fraction of 75% into a three-necked flask equipped with a thermometer and a reflux device, move the three-necked flask into a water bath, control the temperature of the water bath at 65°C, and then pour the three-necked flask into the three-necked flask Add 10g of epichlorohydrin and 30mL of 5% sodium hydroxide solution, and stir for 2 hours to react. After the reaction is over, the product is obtained. The product is moved into a still, and distilled at 80°C. The ethanol solution is recovered to obtain the modified ring Take 8g of 3,3-dichloro-4,4-diaminodiphenylmethane and 100mL of acetone and add them to a three-necked flask with a thermometer and a reflux device, move the three-necked flask into a water bath, and control the temperature of the water bath to After stirring and dissolving at 80°C for 3 minutes, add 1g of sodium amide and 15g of isostearyl alcohol into the three-necked flask,...

example 2

[0022]Take 15g of 2,7-dihydroxynaphthalene and 150mL of ethanol solution with a mass fraction of 75% and add it to a three-necked flask equipped with a thermometer and a reflux device, move the three-necked flask into a water bath, control the temperature of the water bath to 70°C, and then pour it into the three-necked flask Add 13g of epichlorohydrin and 35mL of 5% sodium hydroxide solution, and stir for 2 hours to react. After the reaction is over, the product is obtained. The product is moved into a still, and distilled at 85°C. The ethanol solution is recovered to obtain the modified ring oxygen resin, then take 10g of 3,3-dichloro-4,4-diaminodiphenylmethane and 150mL of acetone into a three-necked flask with a thermometer and a reflux device, move the three-necked flask into a water bath, and control the temperature of the water bath to After stirring and dissolving for 4 minutes at 85°C, add 2g of sodium amide and 18g of isostearyl alcohol into the three-necked flask, an...

example 3

[0024] Take 20g of 2,7-dihydroxynaphthalene and 200mL of 75% ethanol solution into a three-necked flask with a thermometer and a reflux device, move the three-necked flask into a water bath, control the temperature of the water bath to 75°C, and then pour the three-necked flask into the three-necked flask Add 15g of epichlorohydrin and 40mL of 5% sodium hydroxide solution, and stir for 3 hours to react. After the reaction is over, the product is obtained, and the product is moved into a still, and distilled at 90°C, and the ethanol solution is recovered to obtain the modified ring oxygen resin, then take 12g of 3,3-dichloro-4,4-diaminodiphenylmethane and 200mL of acetone and add them to a three-necked flask with a thermometer and a reflux device, move the three-necked flask into a water bath, and control the temperature of the water bath to After stirring and dissolving at 90°C for 5 minutes, add 3g of sodium amide and 20g of isostearyl alcohol into the three-necked flask, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com