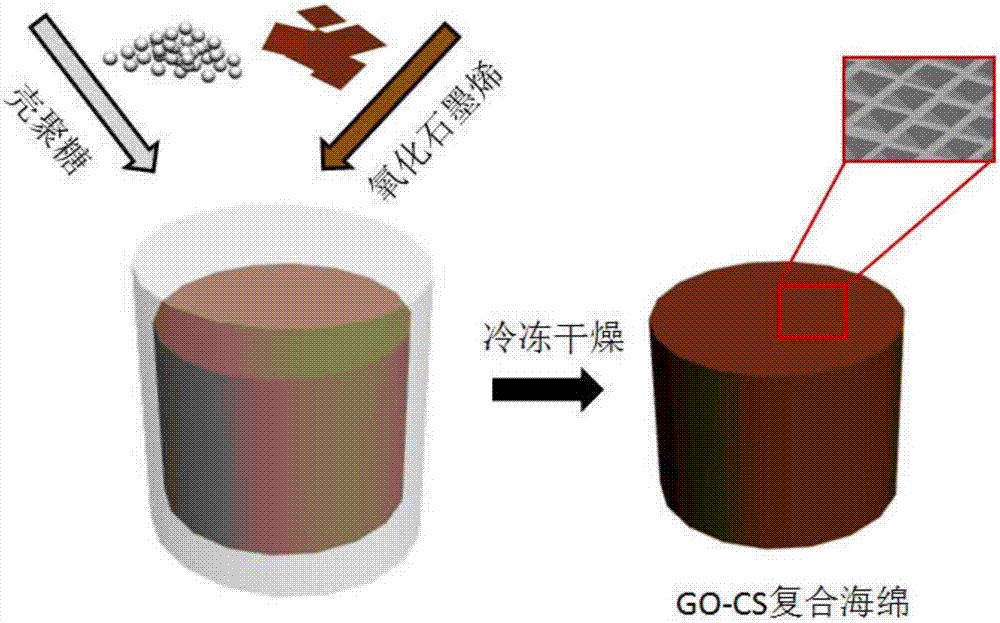

Preparation method and application of multifunctional chitosan composite sponge

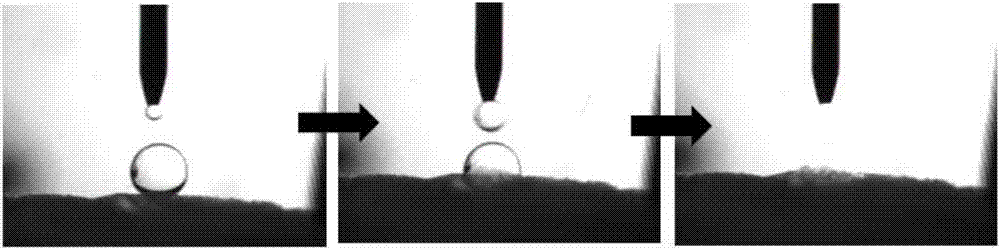

A technology of composite sponge and chitosan, applied in the directions of botanical equipment and methods, applications, separation methods, etc., can solve the problem of no sterilization effect, and achieve the effects of low cost, convenient secondary recovery and high sterilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

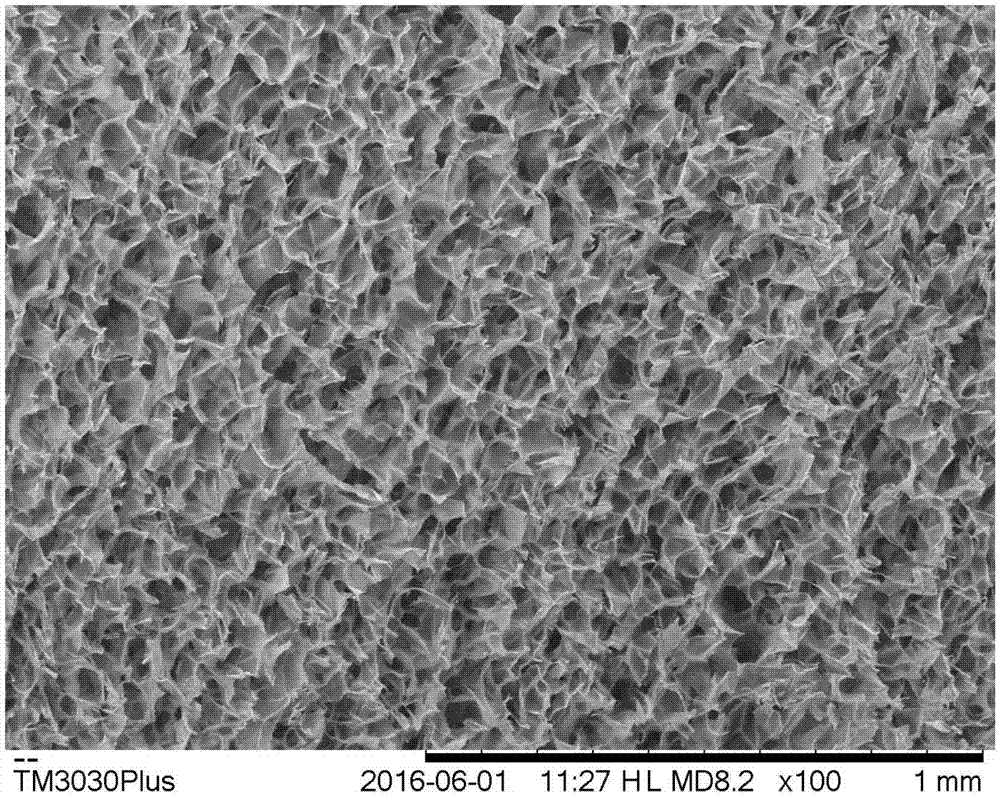

[0032] Example 1: In this embodiment, the GO-CS composite sponge is prepared according to the following steps:

[0033] In the first step, GO nanosheets were prepared by the Hummer method,

[0034] a. The synthesis stage of graphite oxide:

[0035] First, 50ml of concentrated sulfuric acid and 25ml of concentrated nitric acid were added to a round bottom flask, and magnetically stirred for 20 minutes under an ice bath. Then slowly add 4g of natural flake graphite and stir vigorously to avoid graphite agglomeration. After it is uniformly dispersed, slowly add 44g of potassium chlorate (speed control is added within one hour). Finally, the ice bath was removed, and the reaction was allowed to react at room temperature for 96 hours. Because this reaction will produce a large amount of chlorine, use sodium hydroxide solution to absorb the chlorine produced by the reaction. After 96 hours, the natural flake graphite was oxidized to graphite oxide.

[0036] b. Mechanical stripp...

Embodiment 2

[0045] Example 2: In this embodiment, the GO-CS composite sponge is prepared according to the following steps:

[0046] Step 1: Prepare GO nanosheets by the Hummer method,

[0047] a. The synthesis stage of graphite oxide:

[0048] First, 50ml of concentrated sulfuric acid and 25ml of concentrated nitric acid were added to a round bottom flask, and magnetically stirred for 20 minutes under an ice bath. Then slowly add 4g of natural flake graphite and stir vigorously to avoid graphite agglomeration. After it is uniformly dispersed, slowly add 44g of potassium chlorate (speed control is added within one hour). Finally, the ice bath was removed, and the reaction was allowed to react at room temperature for 96 hours. Because this reaction will produce a large amount of chlorine, use sodium hydroxide solution to absorb the chlorine produced by the reaction. After 96 hours, the natural flake graphite was oxidized to graphite oxide.

[0049] b. Mechanical stripping stage:

[00...

Embodiment 3

[0058] Example 3: In this embodiment, the GO-CS composite sponge is prepared according to the following steps:

[0059] Step 1: Prepare GO nanosheets by the Hummer method,

[0060] a. The synthesis stage of graphite oxide:

[0061] First, 50ml of concentrated sulfuric acid and 25ml of concentrated nitric acid were added to a round bottom flask, and magnetically stirred for 20 minutes under an ice bath. Then slowly add 4g of natural flake graphite and stir vigorously to avoid graphite agglomeration. After it is uniformly dispersed, slowly add 44g of potassium chlorate (speed control is added within one hour). Finally, the ice bath was removed, and the reaction was allowed to react at room temperature for 96 hours. Because this reaction will produce a large amount of chlorine, use sodium hydroxide solution to absorb the chlorine produced by the reaction. After 96 hours, the natural flake graphite was oxidized to graphite oxide.

[0062] b. Mechanical stripping stage:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com