Dry material and preparation method and application thereof

A dry-type material and raw material technology, applied in the field of iron and steel smelting, can solve the problems such as the decline in the corrosion resistance and mechanical scouring ability of the matrix structure, the unfavorable high-quality steel billet steelmaking requirements, and the impact on the steel billet quality, etc. High temperature resistance, the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] a plus Al 4SiC 4 The environmentally friendly dry material is prepared from the following raw materials:

[0038] Waste magnesium carbon particles: 70Kg; magnesia through a 200-mesh sieve: 18Kg; glucose: 6Kg; borax: 1Kg; Al 4 SiC 4 Powder: 3Kg; metal silicon powder: 1Kg. The waste magnesia-carbon particles are waste magnesia-carbon brick particles, wherein the content of MgO is more than 70%, and the Al 4 SiC 4 Al in powder 4 SiC 4 The content is more than 90%.

[0039] The preparation process of the environment-friendly dry material described in this embodiment: take the raw materials of the above weight; first mix 50% of the magnesia, glucose, borax, Al 4 SiC 4 Powder and metal silicon powder are premixed for 6 minutes, and put into small bags for later use. Then add the waste magnesium carbon particles, the premix and the rest of the magnesia in the order of mixing and kneading for 5 minutes again, and put them into small bags for packaging.

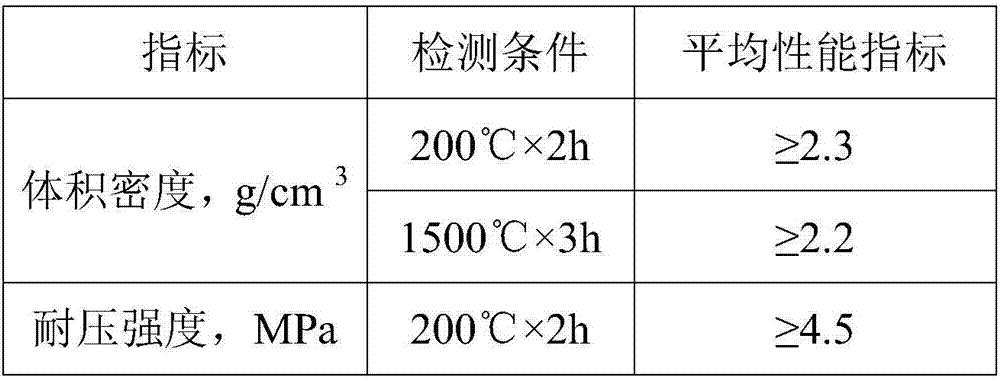

[0040] The d...

Embodiment 2

[0045] a plus Al 4 SiC 4 The environmentally friendly dry material is prepared from the following raw materials:

[0046] Waste magnesium carbon particles: 60Kg; magnesia through a 200-mesh sieve: 30Kg; glucose: 3Kg; borax: 2Kg; Al 4 SiC 4 Powder: 2Kg; metal silicon powder: 0.2Kg. The waste magnesia-carbon particles are waste magnesia-carbon brick particles, wherein the content of MgO is more than 70%, and the Al 4 SiC 4 Al in powder 4 SiC 4 The content is more than 90%.

[0047] The preparation process of the environment-friendly dry material described in this embodiment: take the raw materials of the above weight; first mix 50% of the magnesia, glucose, borax, Al 4 SiC 4 Powder and metal silicon powder are premixed for 6 minutes, and put into small bags for later use. Then add the waste magnesium carbon particles, the premix and the rest of the magnesia in the order of mixing and kneading for 5 minutes again, and put them into small bags for packaging.

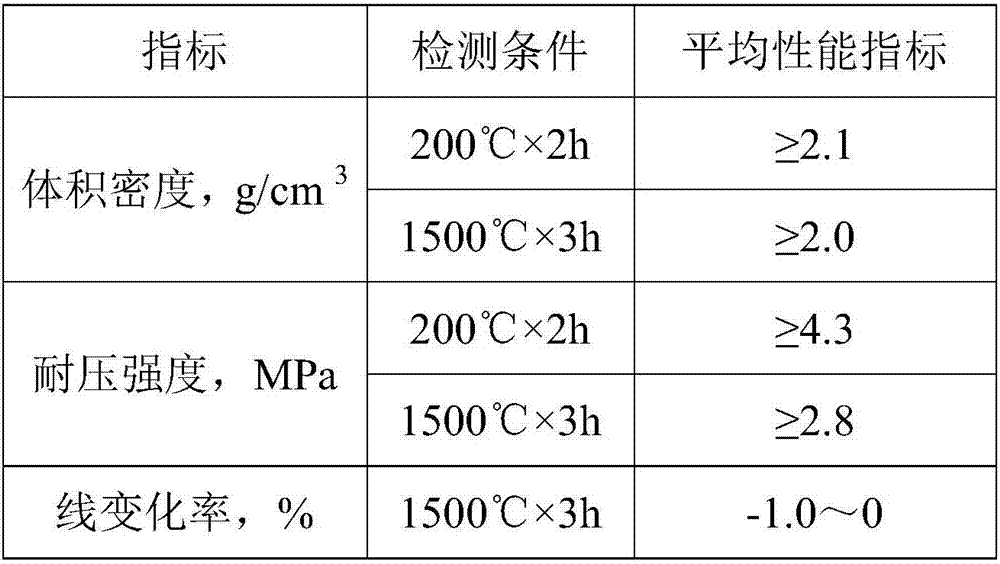

[0048] Th...

Embodiment 3

[0052] a plus Al 4 SiC 4 The environmentally friendly dry material is prepared from the following raw materials:

[0053] Waste magnesium carbon particles: 75Kg; magnesia through a 200-mesh sieve: 15Kg; glucose: 6Kg; borax: 1Kg; Al 4 SiC 4 Powder: 5Kg; metal silicon powder: 1Kg;

[0054] The waste magnesia-carbon particles are waste magnesia-carbon brick particles, wherein the content of MgO is more than 70%, and the Al 4 SiC 4 Al in powder 4 SiC 4 The content is more than 90%.

[0055] The preparation process of the environment-friendly dry material described in this embodiment: take the raw materials of the above weight; first mix 50% of the magnesia, glucose, borax, Al 4 SiC 4 Powder and metal silicon powder are premixed for 6 minutes, and put into small bags for later use. Then add the waste magnesium carbon particles, the premix and the rest of the magnesia in the order of mixing and kneading for 5 minutes again, and put them into small bags for packaging.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com