Preparing method for visible light response CdS/ (cal-Ta2O5-SiO2) composite photocatalyst

A cal-ta2o5-sio2, catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of small specific surface area of raw materials, insufficient stability, and easy destruction of mesopores, etc. Achieve the effects of more active sites, slower recombination speed, and increased photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

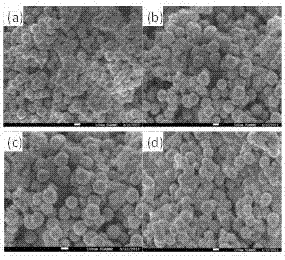

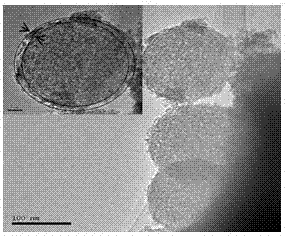

Embodiment 1

[0025] 1) Add ethyl silicate to the ethanol solution of ammonia water and mix well, stir for 14 hours, centrifuge, clean with absolute ethanol and deionized water, dry the product at 80 degrees, and grind the obtained silicon ball sample for backup use.

[0026] 2) TaCl 5 Dissolve in 50ml of ethanol-water (v / v=1:1) solution, adjust pH=4-6 with citric acid, the molar ratio of metal ion to citric acid is 1 / 2. After stirring at room temperature for 1-2 hours, add silicon spheres, stir for 3-8 hours, centrifuge, wash thoroughly with deionized water and absolute ethanol, and dry at 80°C for 14 hours to obtain the desired sample.

[0027] 3) TaCl 5 Dissolve in 50ml of ethanol-water (v / v=1:1) solution, adjust pH=4-6 with citric acid, the molar ratio of metal ion to citric acid is 1 / 2. After stirring at room temperature for 1-2 hours, add the sample prepared in the second step, stir for 3-8 hours, centrifuge, wash thoroughly with deionized water and absolute ethanol, and dry at 80°...

Embodiment 2

[0033] 1) Add ethyl silicate to the ethanol solution of ammonia water and mix well, stir for 14 hours, centrifuge, clean with absolute ethanol and deionized water, dry the product at 80 degrees, and grind the obtained silicon ball sample for backup use.

[0034] 2) TaCl 5 Dissolve in 50ml of ethanol-water (v / v=1:1) solution, adjust pH=4-6 with citric acid, the molar ratio of metal ion to citric acid is 1 / 2. After stirring at room temperature for 1-2 hours, add silicon balls, stir for 3-8 hours, centrifuge, wash thoroughly with deionized water and absolute ethanol, dry at 80°C for 14 hours, and calcinate at 400-600°C for 2 hours to obtain the desired sample .

[0035] 3) TaCl 5 Dissolve in 50ml of ethanol-water (v / v=1:1) solution, adjust pH=4-6 with citric acid, the molar ratio of metal ion to citric acid is 1 / 2. After stirring at room temperature for 1-2 hours, add the sample prepared in the second step, stir for 3-8 hours, centrifuge, wash thoroughly with deionized water ...

Embodiment 3

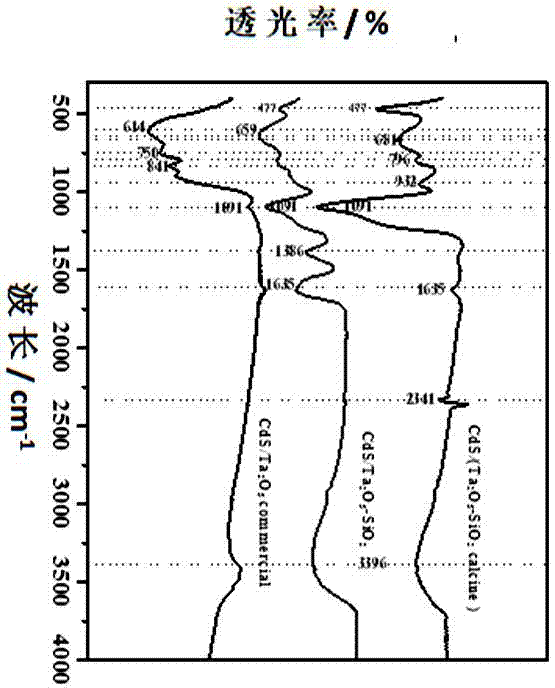

[0041] Investigate the prepared CdS / (Ta 2 o 5 -SiO 2 ) and CdS / (Cal-Ta 2 o 5 -SiO 2 ) Catalytic activity to degrade RhB under visible external light. Ta 2 o 5 CdS / (Ta 2 o 5 -SiO 2 ), CdS / (Cal-Ta 2 o 5 -SiO 2 ) and control CdS / Ta 2 o 5 -commercial 0.1g is put into 200ml rhodamine B (0.01g / L), stirred in the dark for 30 minutes to achieve adsorption-desorption equilibrium, then irradiated with visible light, take a sample every 10 minutes, and measure it with a liquid UV-visible spectrophotometer Absorbance, calculate C / C 0 and -Ln (C / C 0 ), the result is as Figure 5 .

[0042] CdS / (cal-Ta 2 o 5 -SiO 2 ) has the highest photocatalytic activity, and can degrade more than 95% in 30 minutes, far exceeding CdS / (Ta 2 o 5 -SiO 2 ) and CdS / Ta 2 o 5 -commercial degradation efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com