Culture device for lactic acid bacteria

A culture device and colony technology, applied in the field of microaerophilic microorganisms or obligate anaerobic microorganisms, cultivating and detecting microaerobic resistant microorganisms, can solve the problems of high cost, cumbersome and inconvenient device assembly and/or use, and eliminate the need , save the effect of incubation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0184] Embodiment 1. The preparation of the culture device that produces anaerobic environment independently .

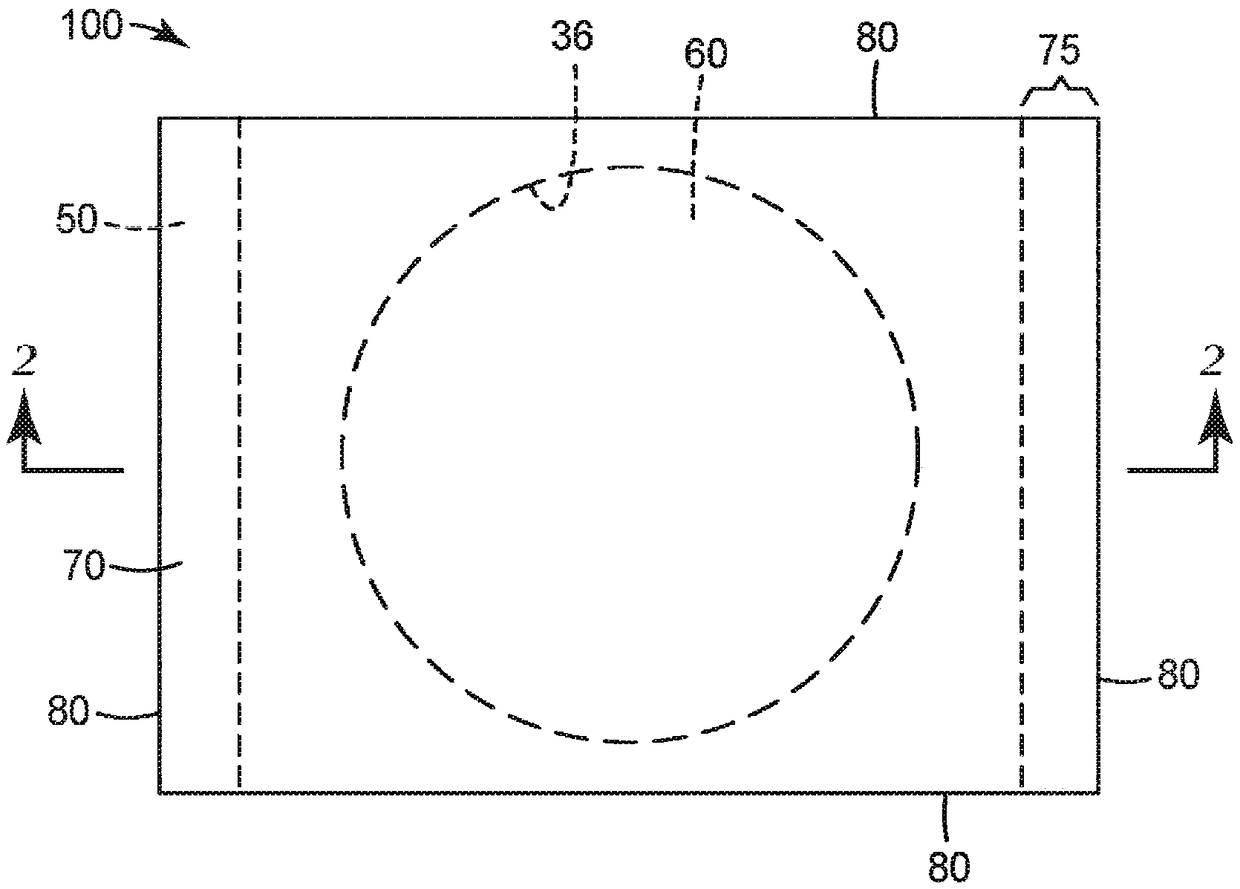

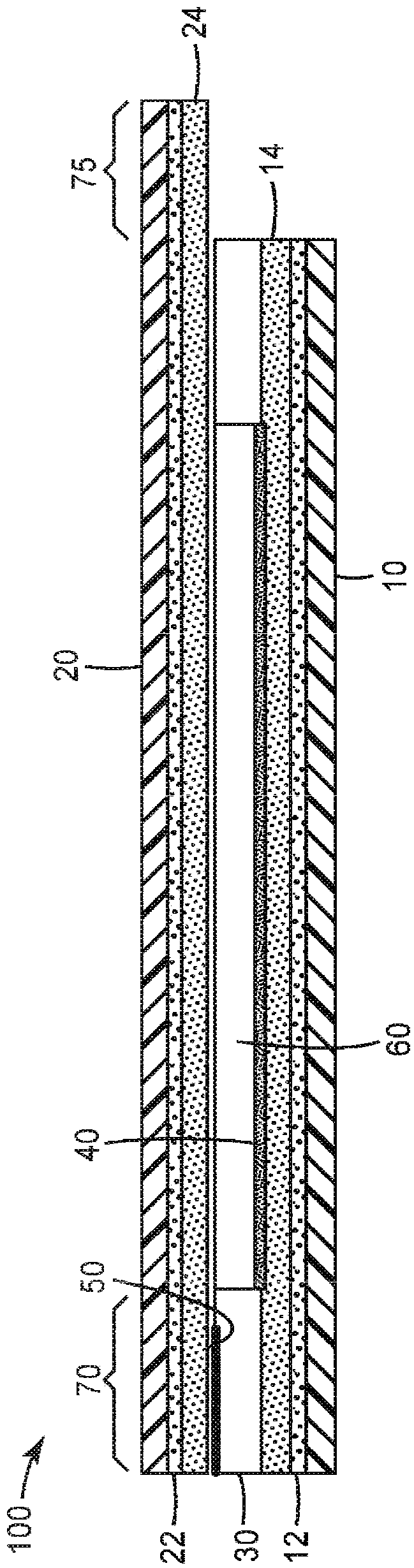

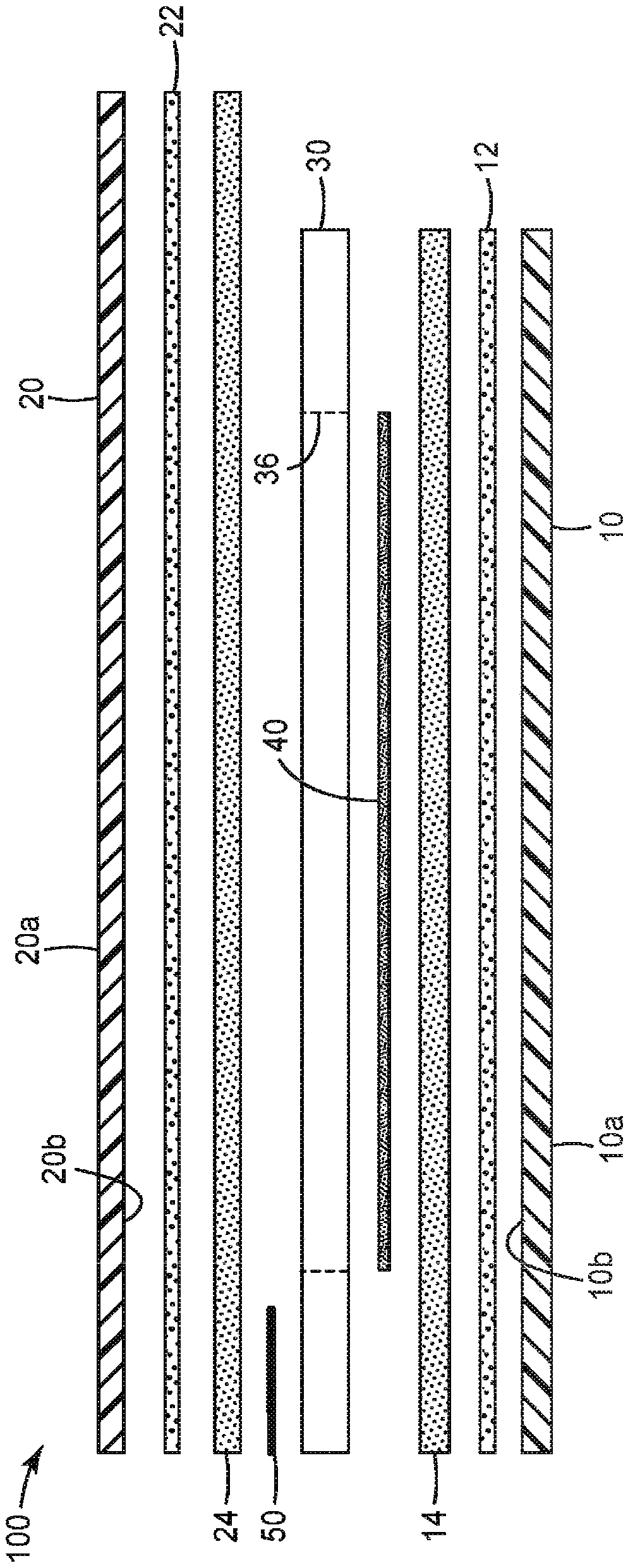

[0185] Construction basis figure 1 A culture device that autonomously generates an anaerobic environment. The base was made of 5 mil (0.127 mm) thick polyester film (MELINEX grade 377, biaxially oriented polyester (PET) film, available from DuPont Teijin; Chester, VA). )composition. The nutrient powder formulation (listed in Table 1) and guar gum (16 g / L) were stirred in deionized water to achieve a substantially homogeneous mixture. The pH of the mixture was targeted at 5.8 + / - 0.5, adjusted with acid or base if necessary to meet the target. This mixture was knife coated onto a substrate and dried in a convection oven at 210°F (98.9°C) for 8 minutes as described in US Patent 4,565,783. Apply the nutrient layer to a target coat weight (after drying) of 0.56g / 24in 2 (3.6mg / cm 2 )thickness of. After drying, approximately 20 mil (0.508 mm) thick polyethylene f...

Embodiment 2

[0191] A culture device autonomously producing an anaerobic environment was prepared as described in Example 1, except that instead of coating with the powder mixture of Example 1, guar gum (89.7% by weight), sodium ascorbate (10% by weight) and carbonic acid A powder mixture of sodium hydrogen (0.3% by weight) coated the binder of the protective layer.

Embodiment 3

[0193] A culture device autonomously producing an anaerobic environment was prepared as described in Example 1, except that instead of coating with the powder mixture of Example 1, guar gum (89.5% by weight), sodium ascorbate (10% by weight) and carbonic acid A powder mixture of sodium hydrogen (0.5% by weight) coated the binder of the protective layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com