Preparation method of fluorine removal agent for water

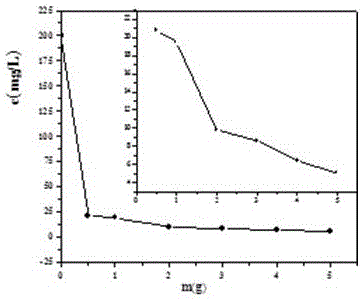

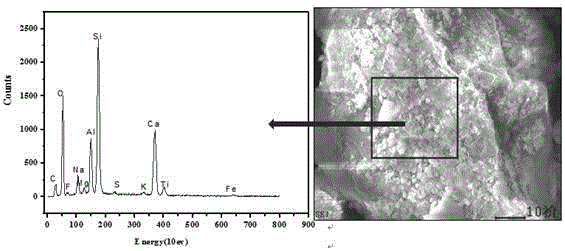

A technology of defluoridation agent and water body, which is applied in the field of waste resource utilization, can solve the problems of high cost of defluoridation, secondary pollution of waste concrete, etc., and achieve the effect of wide source of raw materials, increased specific surface area and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, the method for preparing water body defluoridation agent by using waste concrete is as follows:

[0027] (1) Select waste concrete from construction waste, and use a small hammer crusher for primary crushing, use a square hole sieve to control the particle size of the waste concrete after primary crushing d≤10mm, and put the waste concrete after primary crushing into a muffle furnace Low-temperature pre-calcination is carried out to weaken the bond strength between aggregate and cement stone in waste concrete. The specific calcination conditions are: heating up to 250°C at a rate of 6°C / min, keeping the temperature for 20 minutes and then cooling naturally to 25°C.

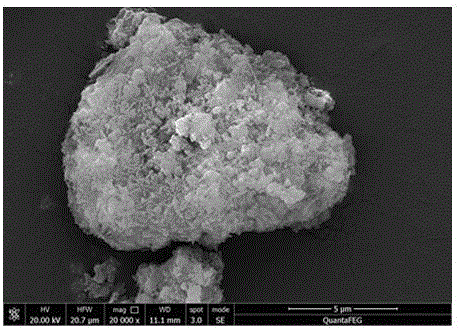

[0028] (2) Vibrate the calcined waste concrete in an electromagnetic vibrating pulverizer to separate the coarse aggregate from the waste cement stone, and put the separated cement stone into a ball mill for grinding to further increase its microstructure defects , to increase its specif...

Embodiment 2

[0031] In this embodiment, the method for preparing water body defluoridation agent by using waste concrete is as follows:

[0032] (1) Select waste concrete from construction waste, and use a small hammer crusher for primary crushing, use a square hole sieve to control the particle size of the waste concrete after primary crushing d≤10mm, and put the waste concrete after primary crushing into a muffle furnace Low-temperature pre-calcination is carried out to weaken the bond strength between the aggregate and cement stone in the waste concrete. The specific calcination conditions are: heating up to 400°C at a rate of 8°C / min, keeping the temperature for 20 minutes and then cooling naturally to 20°C.

[0033] (2) Vibrate the calcined waste concrete in an electromagnetic vibrating pulverizer to separate the coarse aggregate from the waste cement stone, and put the separated cement stone into a ball mill for grinding to further increase its microstructure defects , to increase it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com