Monatomic silver-carbon point and carbon nitride composite catalyst, preparation method and application thereof

A composite catalyst and carbon nitride technology, which is applied in chemical instruments and methods, light water/sewage treatment, water pollutants, etc., can solve the problems of large silver ion particles and limit the catalytic performance of composite catalysts, and achieve good material stability , high application prospects and use value, good repeatability and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

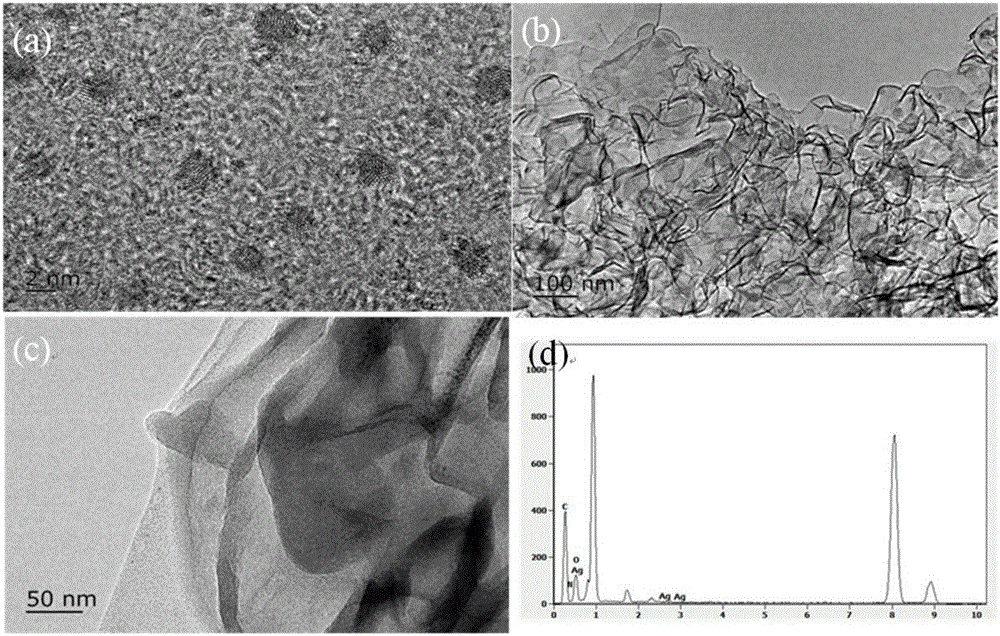

[0038] The preparation of a kind of monoatomic silver-carbon dot and carbon nitride composite catalyst comprises the following steps:

[0039] 1. Weigh 6.005g of sodium tricyanomethane and dissolve in 12ml of water to obtain solution A. Weigh 9.106g silver nitrate and dissolve in 18ml water to obtain solution B. Heat the two solutions of A and B to 80°C respectively. With vigorous stirring, solution B was added dropwise to solution A, and kept stirring at room temperature for 8 h. Suction filter the flocs, wash them four times with ultrapure water, dry them in vacuum at 60°C and grind them to obtain a white powder, which is silver tricyanomethane.

[0040] 2. Weigh 1 g of citric acid in a polytetrafluoroethylene high-temperature hydrothermal reactor, add 0.3 ml of ethylenediamine and 10 ml of ultrapure water into it, transfer the reactor to an oven and react at 200°C for 5 hours. After it was cooled to room temperature, a brownish-yellow aqueous solution was obtained. The s...

Embodiment 2

[0056] The preparation of a kind of monoatomic silver-carbon dot and carbon nitride composite catalyst comprises the following steps:

[0057] 1. Weigh 6.005g of sodium tricyanomethane and dissolve in 12ml of water to obtain solution A. Weigh 9.106g silver nitrate and dissolve in 18ml water to obtain solution B. Heat the two solutions of A and B to 60°C respectively. With vigorous stirring, solution B was added dropwise to solution A, and kept stirring at room temperature for 8 h. Suction filter the flocs, wash them with ultrapure water four times, dry them in vacuum at 80°C, and then grind them to obtain white powder, which is silver tricyanomethane.

[0058] 2. Weigh 3g of citric acid in a polytetrafluoroethylene high-temperature hydrothermal reactor, add 0.7g of ethylenediamine and 15ml of ultrapure water into it, transfer the reactor to an oven and react at 150°C for 3h. After it was cooled to room temperature, a brownish-yellow aqueous solution was obtained. The soluti...

Embodiment 3

[0061] The preparation of a kind of monoatomic silver-carbon dot and carbon nitride composite catalyst comprises the following steps:

[0062] 1. Weigh 6.005g of sodium tricyanomethane and dissolve in 12ml of water to obtain solution A. Weigh 9.106g silver nitrate and dissolve in 18ml water to obtain solution B. Heat the two solutions of A and B to 80°C respectively. With vigorous stirring, solution B was added dropwise to solution A, and kept stirring at room temperature for 8 h. Suction filter the flocs, wash them with ultrapure water for 5 times, dry them in vacuum at 60°C, and then grind them to obtain a white powder, which is silver tricyanomethane.

[0063] 2. Weigh 1 g of citric acid in a polytetrafluoroethylene high-temperature hydrothermal reaction vessel, add 0.3 ml of ethylenediamine into it, transfer the reaction vessel to an oven and react at 220° C. for 3 hours. After it was cooled to room temperature, a brownish-yellow aqueous solution was obtained. The solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com