Deburring, grinding and polishing integrated ultra-fine processing machine

A deburring, ultra-fine technology, applied in grinding/polishing equipment, metal processing mechanical parts, grinding/polishing safety devices, etc., can solve the problems of surface damage, high cost, mutual bumps, etc., to achieve automatic production , Improve the service life and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

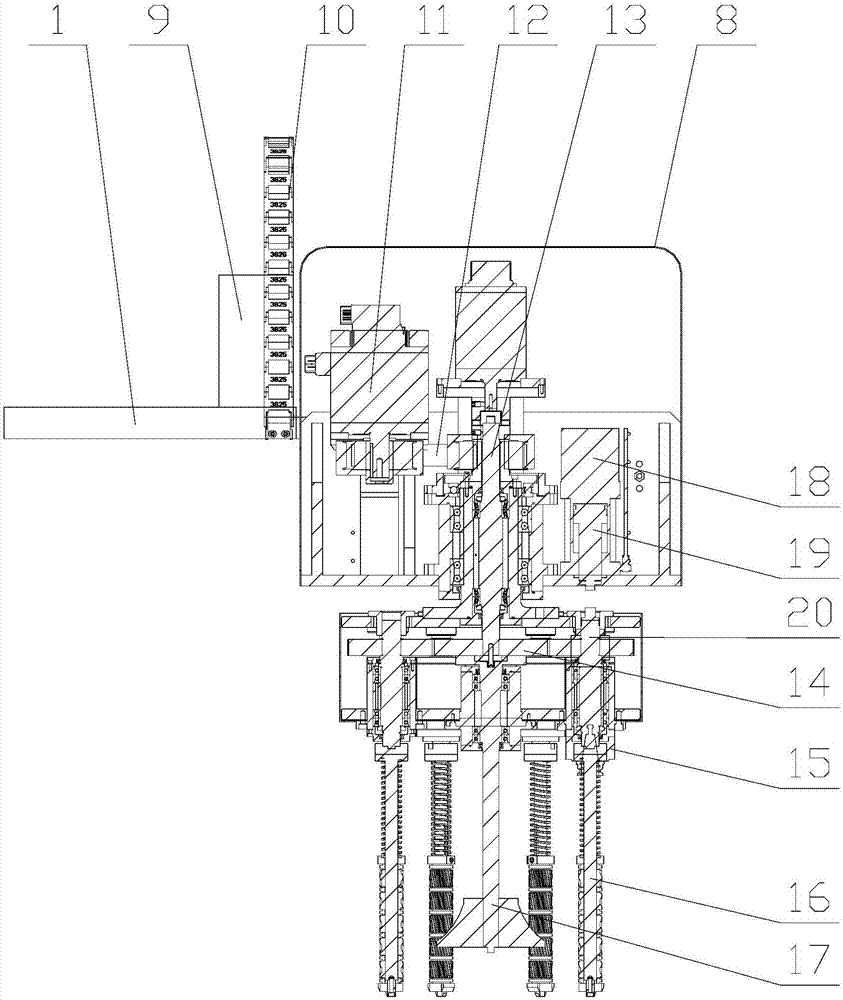

[0041] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0042] like Figure 1 to Figure 5 As shown, a superfine processing machine integrating deburring, grinding and polishing includes a frame 1, a control box 2 is arranged on the frame 1, a planetary mechanism 3 is arranged inside the frame 1, and the planetary A storage tank 4 is provided below the mechanism 3, a grinding fluid filling circulation filter mechanism 5 is provided on one side of the storage tank 4, and a tooling fixture 6 is provided on the other side of the storage tank 4;

[0043] The operating principle and implementation of the device of the present invention are as follows:

[0044] Ⅰ. Turn on the main switch of the equipment and power on, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com