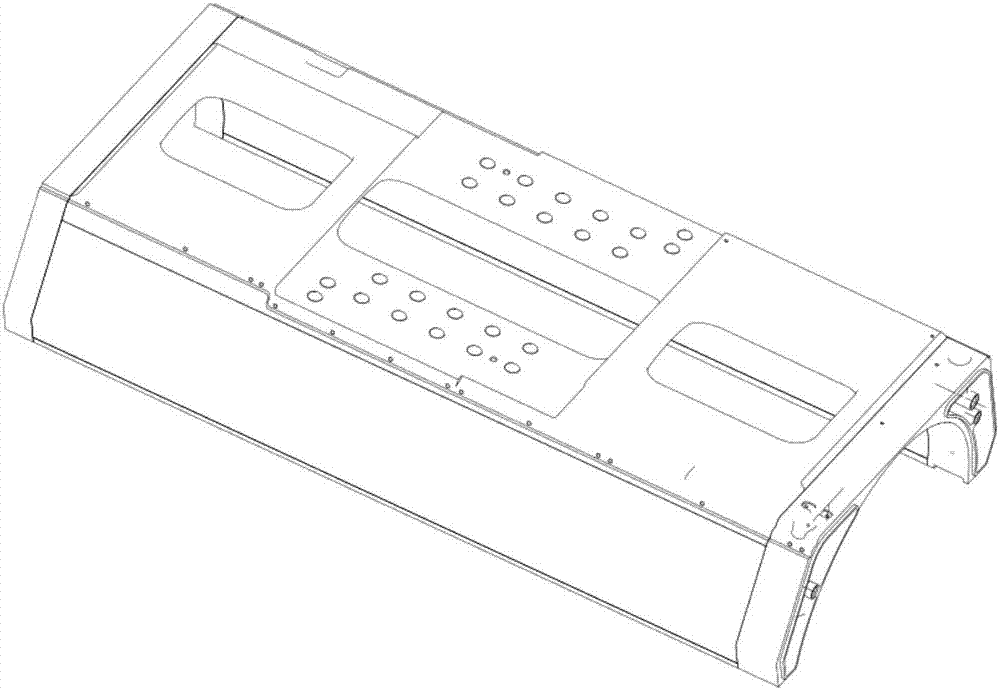

Laser welding technological method for saddle-shaped aluminum alloy structure

A technology of laser welding and process method, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve the problems of long welding seam length, poor forming accuracy of skin components, long welding process flow, etc., and achieve excessively smooth welding seam. , to avoid internal cracks in the weld, the effect of excellent comprehensive mechanical properties of the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

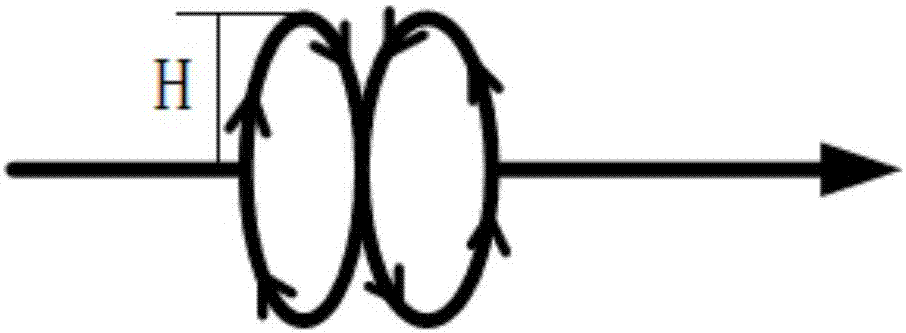

[0038] Before laser welding, clean the scale, oil and other impurities within the range of (20-50) mm from the center of the weld; during welding, the laser power P is 4400W, the laser beam swing path is an "∞" path, and the swing amplitude is H is 2mm, the swing frequency is 300Hz, the welding speed v is 1.8m / min, the spot diameter D is 0.3mm, and the defocus amount 1 is 0mm. 99.99% high-purity argon is used for front protection, and the front gas flow rate is 16L / min.

[0039]The welding results show that the surface of the weld seam is well formed, without pores, cracks, depressions, undercuts and other defects. The average tensile strength of the weld at room temperature can reach 305MPa, and the average elongation after fracture is 7.0%. The weld seam quality of the joint meets the requirements of Class I weld seam in the Q / SB 535-2013 "Technical Conditions for Laser Welding of Aluminum Alloys".

Embodiment 2

[0041] Before laser welding, clean the scale, oil and other impurities within the range of (20-50) mm from the center of the weld; during welding, the laser power P is 5200W, the swing path of the laser beam is an "∞" path, and the swing amplitude is H is 3mm, the swing frequency is 200Hz, the welding speed v is 1.8m / min, the spot diameter D is 0.3mm, and the defocus amount 1 is 0mm. 99.99% high-purity argon is used for front protection, and the front gas flow rate is 16L / min.

[0042] The welding results show that the surface of the weld seam is well formed, without pores, cracks, depressions, undercuts and other defects. The average tensile strength of the weld at room temperature can reach 298MPa, and the average elongation after fracture is 7.2%. The weld seam quality of the joint meets the requirements of Class I weld seam in the Q / SB 535-2013 "Technical Conditions for Laser Welding of Aluminum Alloys".

Embodiment 3

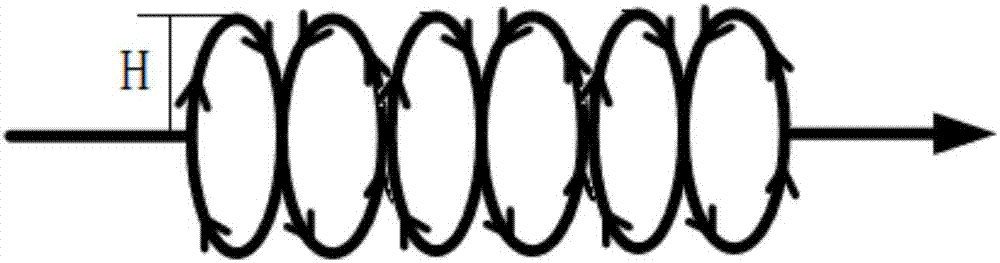

[0044] Before laser welding, clean up the scale, oil and other impurities within the range of (20-50) mm from the center of the weld; during welding, the laser power P is 4400W, the welding speed v is 1.8m / min, and the spot diameter D is 0.3mm , the defocus amount 1 is 0mm. 99.99% high-purity argon is used for front protection, the front gas flow rate is 15L / min, high-purity argon is passed inside the structural parts for back protection, and the back gas flow rate is 4L / min. The laser beam swing frequency is 400Hz and the amplitude is 2mm.

[0045] The welding results show that the surface of the weld seam is well formed, without pores, cracks, depressions, undercuts and other defects. The average tensile strength of the weld at room temperature can reach 298MPa, and the average elongation after fracture is 7.3%. The weld seam quality of the joint meets the requirements of Class I weld seam in the Q / SB 535-2013 "Technical Conditions for Laser Welding of Aluminum Alloys".

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com