Opposite front light-in high-power photoconductive switch device and making method thereof

A photoconductive switch, high-power technology, applied in the direction of semiconductor devices, electrical components, final product manufacturing, etc., can solve problems such as easy breakdown, electrode ablation, and reduced excitation efficiency, so as to improve the withstand voltage value of the switch and avoid edge strikes Wear, improve the effect of light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

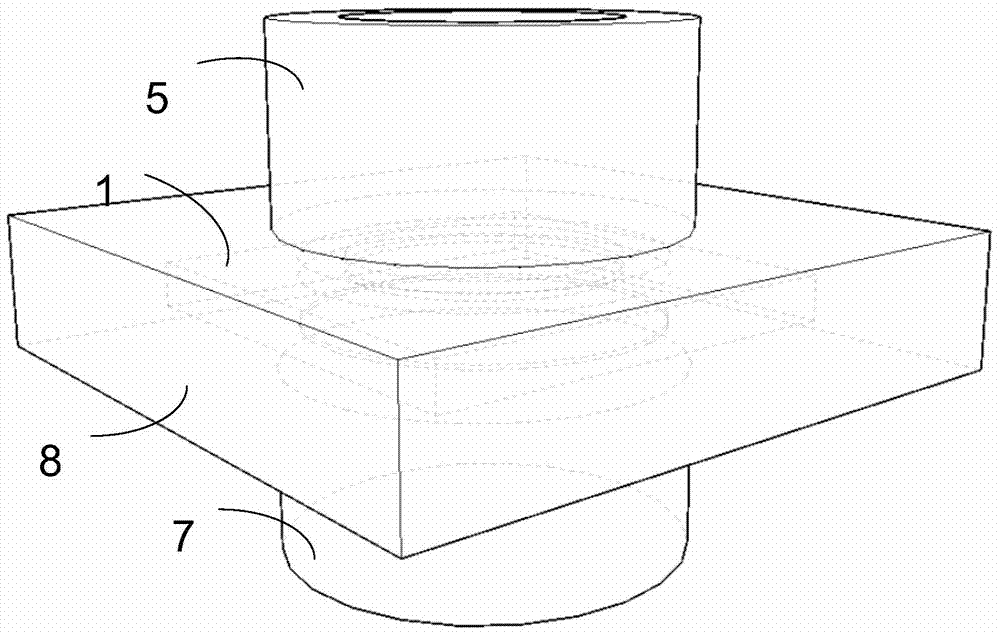

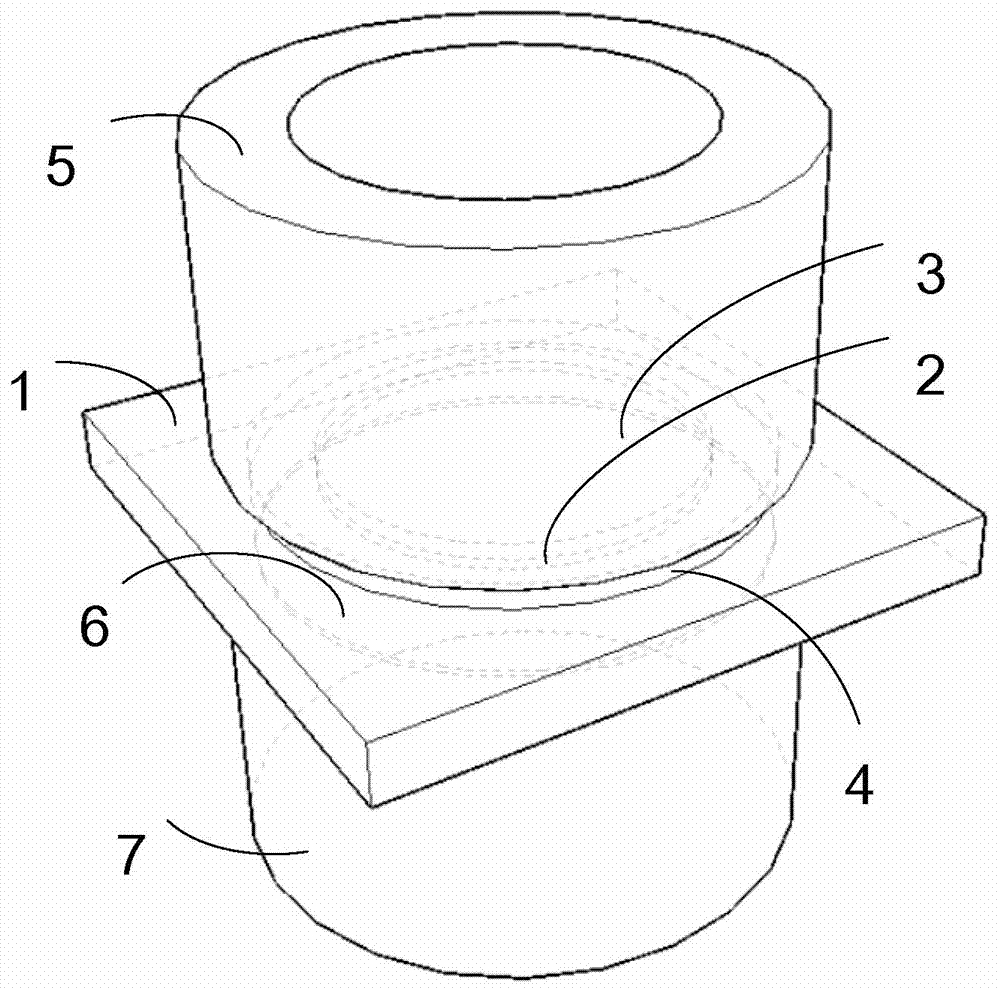

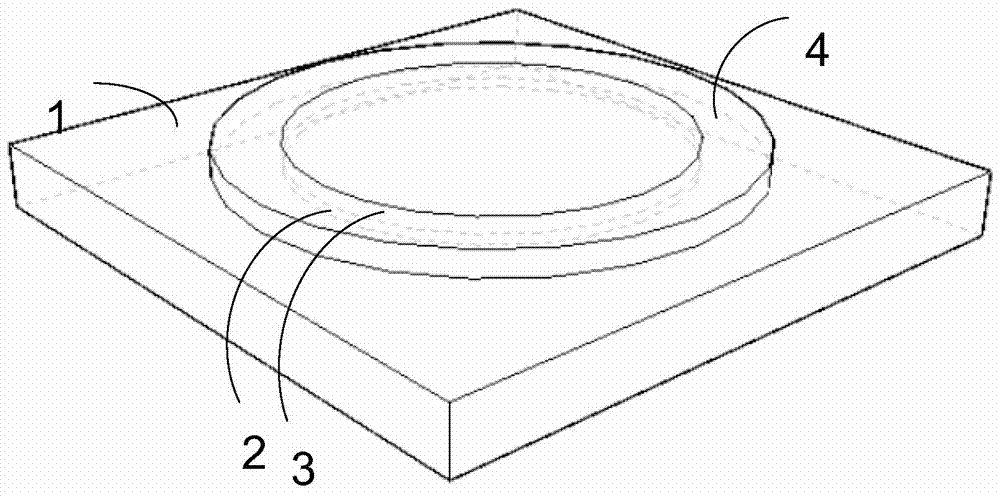

[0071] In this embodiment, a high-resistance 4H-SiC single crystal is used as the substrate material, and the crystal is cut into a 1mm thin slice along the (11-20) plane, and then cut into a 10mm X 10mm square high-resistance semiconductor 1, and six surfaces are polished to a roughness less than 0.2nm. After cleaning by the standard RCA process, etch at 1200°C for 0.5 hours in hydrogen with a pressure of 1 bar to eliminate the surface damage layer. Before use, immerse in 10% HF acid for 10 minutes, rinse with pure water for 30 minutes, use magnetron sputtering equipment to sputter metal Ni on one surface of the high-resistance semiconductor 1, and obtain a ring structure by photolithography (ie metal ring 4) and then annealed at 1100°C. Subsequently, the AlZnO transparent conductive layer 2 is deposited by magnetron sputtering equipment. Then adopt PECVD to deposit SiO2 anti-reflective passivation layer 3, such as image 3 shown. Deposit Ag on the other opposite surface ...

Embodiment 2

[0073] In this embodiment, a high-resistance 4H-SiC single crystal is used as the substrate material, and the crystal is cut into a 1mm thin slice along the (11-20) plane, and then cut into a disc-shaped high-resistance semiconductor 9 with a diameter of 10mm, and two large The face and sides are polished to a roughness of less than 0.2nm. After cleaning by the standard RCA process, etch at 1200°C for 0.5 hours in hydrogen with a pressure of 1 bar to eliminate the surface damage layer. Before use, immerse in HF acid with a concentration of 10% for 10 minutes, rinse with pure water for 30 minutes, use CVD equipment, heat at 1200°C under Ar atmosphere to form a graphene transparent conductive layer on the two facing large surfaces of SiC, Obtain circular graphene transparent conductive layer 10,11 by etching process, such as Figure 7 shown. Then, a magnetron sputtering device is used to sputter metal Ni on one surface of the high-resistance semiconductor 9, and a ring structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com