High-sensitivity netted graphene/elastomer strain sensor and preparation method thereof

A mesh graphene, strain sensor technology, applied in graphene, chemical instruments and methods, electric/magnetic solid deformation measurement, etc., can solve the problems of low sensitivity, high cost, easy structure damage, etc. of the sensor, and achieve widening applications range, increased service life, high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: disperse graphite oxide in an aqueous solution, and ultrasonicate at 40 kHz for 3 hours to obtain a graphene oxide dispersion liquid with a single-sheet dispersion concentration of 0.5 mg / mL.

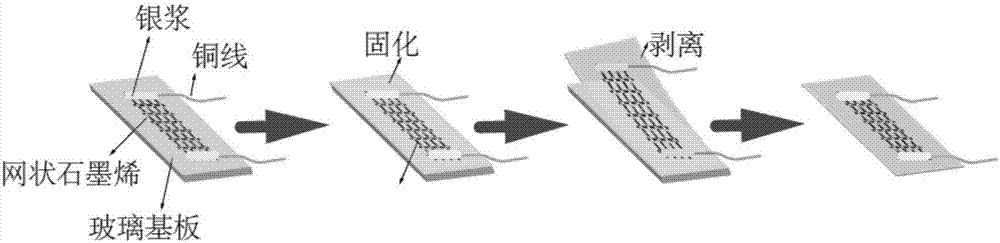

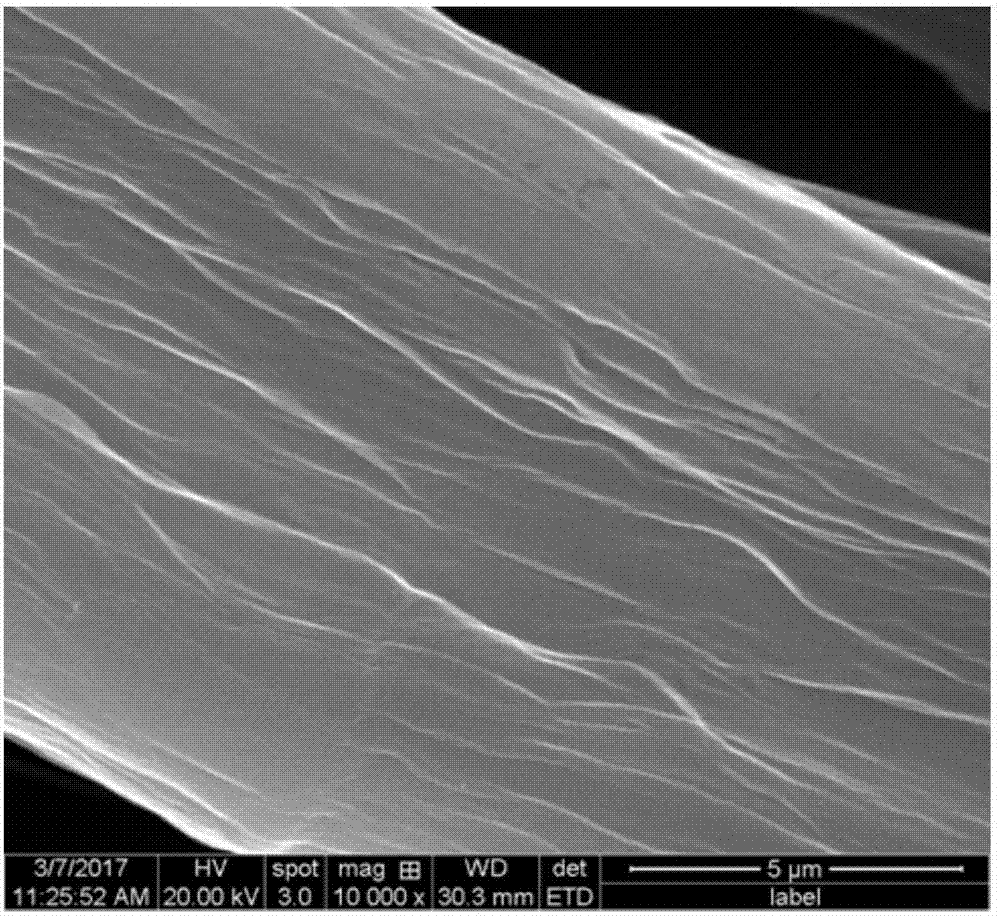

[0028] Step 2: Use the absorbent cotton bandage as a template, wash it three times with deionized water and ethanol alternately, dry it in an oven at 80°C, and soak the absorbent cotton bandage in the graphene oxide dispersion while maintaining a vacuum pressure of -0.05MPa , soaked for 0.5h, took out the absorbent cotton bandage, put it in an oven at 60°C for 2h, then transferred it to an oven at 80°C, and dried it for 1h to obtain a graphene oxide-coated absorbent cotton bandage. The sample obtained above is heated at 250° C. to 310° C. for 3 hours, and then heated at 750° C. to 850° C. for 1 hour to obtain 1 nm network graphene. The network structure of graphene is as follows: figure 1 shown.

[0029] Step 3, place the graphene network obtained in step 2 on a glass sl...

Embodiment 2

[0032] Repeat embodiment 1 method, but in step one, ultrasonic power is 80kHz, and ultrasonic time is 2h, and the graphene oxide concentration that obtains is 2mg / mL; In step two, soaking time is 1h, and the graphene network thickness that obtains is 2nm; in step 3, the elastomer emulsion is styrene-butadiene rubber and natural rubber, the volume ratio is 1:1, the curing temperature is 60°C, and the curing time is 5h.

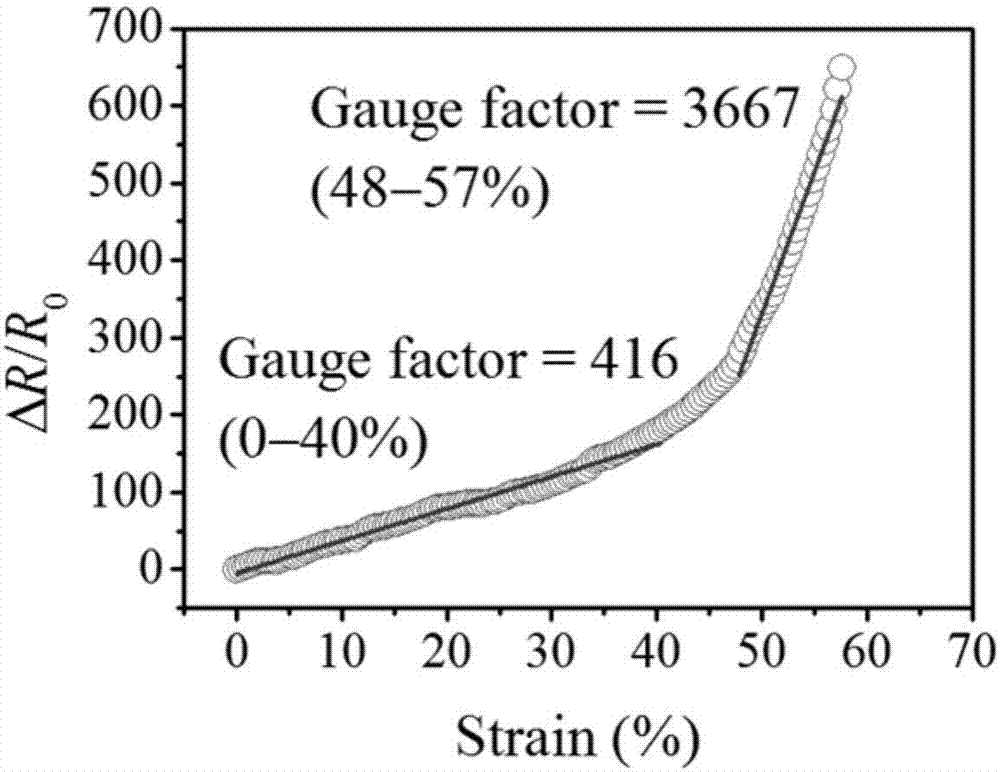

[0033] The sensitivity index Gaugefactor (GF) of the sensor is about 390 (00 ) / R 0 Δε, where R represents the resistance before deformation, R 0 Indicates the resistance after deformation, and Δε indicates the strain). When the strain is 7.5% and 50%, after repeated 50 times, the sensitivity indexes are 389 and 3576 respectively.

Embodiment 3

[0035] Repeat embodiment 1 method, but in step one, ultrasonic power is 100kHz, and ultrasonic time is 1h, and the graphene oxide concentration that obtains is 3mg / mL; In step two, soaking time is 2h, and the graphene network thickness that obtains is 3nm; in step 3, the elastomer emulsion is carboxylated nitrile rubber, the curing temperature is 80° C., and the curing time is 2 hours.

[0036] The sensitivity index Gaugefactor (GF) of the sensor is about 400 (00 ) / R 0 Δε, where R represents the resistance before deformation, R 0 Indicates the resistance after deformation, and Δε indicates the strain). When the strain is 7.5% and 50%, after repeated 50 times, the sensitivity indexes are 390 and 3600 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com