Hollow organic microporous nanosphere cross-linked network and synthesis method and application thereof

A technology of cross-linked network and synthesis method, applied in the field of cross-linked network of hollow organic microporous nanospheres and its synthesis, can solve the problems of large size and uneven size distribution of COF spheres.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

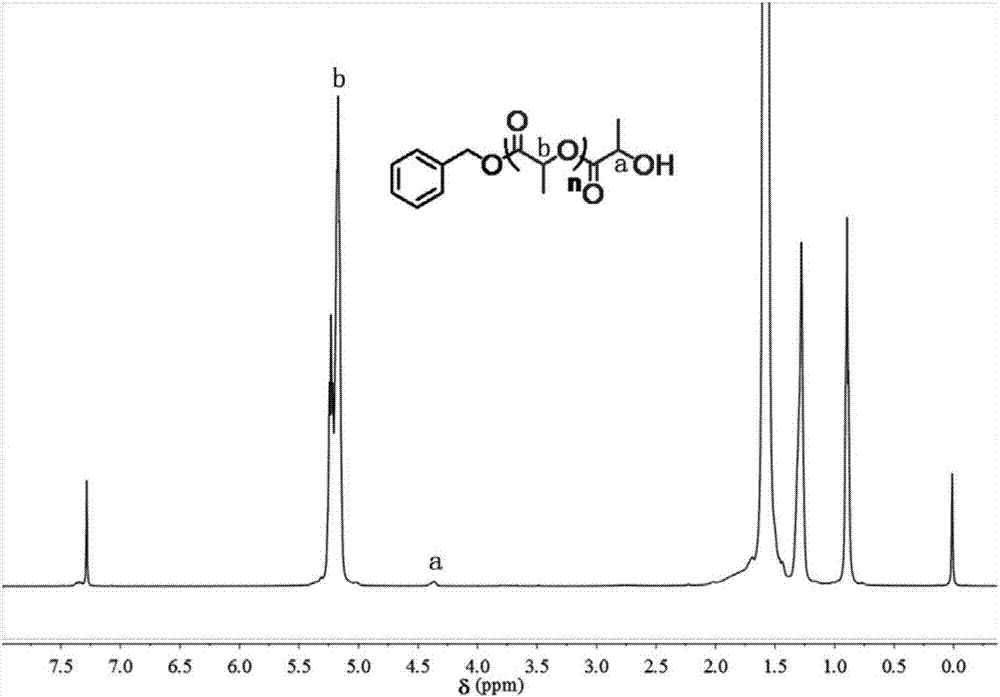

[0104] The synthesis of embodiment 1 diblock copolymer (PLA-b-PS)

[0105] Firstly, polylactic acid was synthesized by ring-opening polymerization method, and then polylactic acid was modified with a chain transfer agent at the end, and finally polystyrene was connected by reversible addition-fragmentation chain transfer polymerization method to obtain a diblock copolymer PLA-b-PS.

[0106] Its synthesis process is shown in formula (VI):

[0107]

[0108] Wherein, n=150, m=250.

[0109] Specifically include the following steps:

[0110] (a-1) Synthesis of PLA

[0111] Benzyl alcohol (10 μl), D,L-lactide (1.3 g), and stannous octoate (19 mg) were added to the reaction tube, and the tube was sealed at 130° C. for 3 hours. After the reaction was completed, it was dissolved in 20 ml of dichloromethane, precipitated in methanol, collected and dissolved in dichloromethane, precipitated in methanol again, and repeated three times in sequence. The finally obtained white product...

Embodiment 2

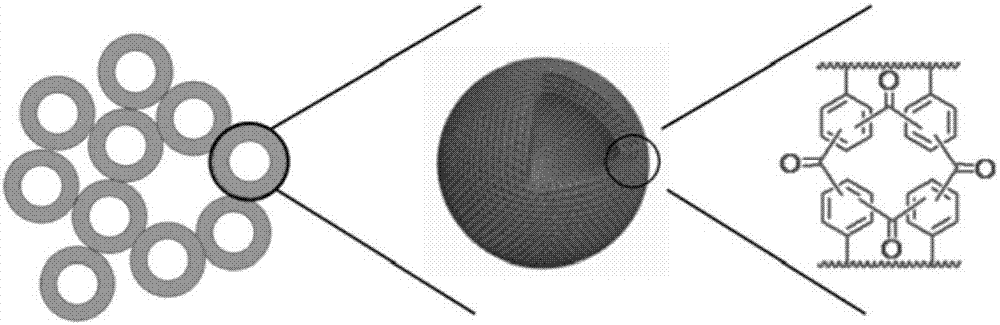

[0118] Example 2 Synthesis of Hollow Organic Microporous Nanosphere Crosslinked Network

[0119] Dissolve the two-block copolymer PLA-b-PS synthesized in Example 1 in carbon tetrachloride, then add a certain amount of anhydrous aluminum chloride, and place it in a closed container at 90°C for 24 hours. After the reaction, respectively The obtained solid was washed three times with a mixed solution of 95% ethanol and water (4:1) and methanol, and finally vacuum-dried at room temperature for 24 hours to obtain the hollow organic microporous nanosphere cross-linked network. Specifically include the following steps:

[0120] Diblock copolymer PLA-b-PS (700 mg) was dissolved in 7 ml of carbon tetrachloride, and after complete dissolution, 2.5 g of anhydrous aluminum chloride was added. After stirring for 5 minutes, tighten the lid to close the reactor, move it into a 90°C oil bath, and let it stand for 24 hours to react. After the reaction solution is cooled to room temperature, ...

Embodiment 3

[0124] The synthesis of embodiment 3 different molecular weight diblock copolymers PLA-b-PS

[0125] (a) PLA 60 The synthesis of D, L-lactide, benzyl alcohol, and the molar ratio of stannous octoate are controlled in the ratio of 60:1:0.5, and the reaction time is 0.5 hour. Other reaction conditions are the same as in Example 1, and polymerization can be obtained Polylactic acid with a degree of 60.

[0126] (b) PLA 60 -b-PS 60 Synthesis of PLA 60 -TC, AIBN, the molar ratio of styrene is controlled in the ratio of 1:0.1:400, and the reaction time is 6 hours, and other reaction conditions are the same as embodiment 1, can obtain diblock copolymer PLA 60 -b-PS 60 .

[0127] (c) PLA 150 -b-PS 130 Synthesis of PLA 150 -TC, AIBN, the molar ratio of styrene is controlled in the ratio of 1:0.1:1000, and the reaction time is 7 hours, and other reaction conditions are the same as Example 1, can obtain diblock copolymer PLA 150 -b-PS 130 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com