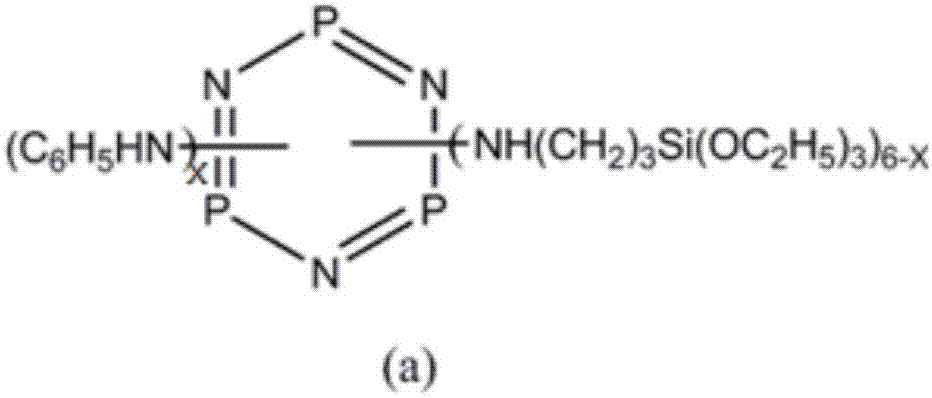

P-N-Si ternary synergistic flame retardant as well as preparation method and application thereof

A phosphorus-nitrogen-silicon and synergistic flame-retardant technology is applied in the field of phosphorus-nitrogen-silicon ternary synergistic flame retardants and their preparations, which can solve the problems of poor flame retardancy and high phosphorus content in flame retardants, and achieve good thermal stability and flame retardancy. The effect of improved combustion performance and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

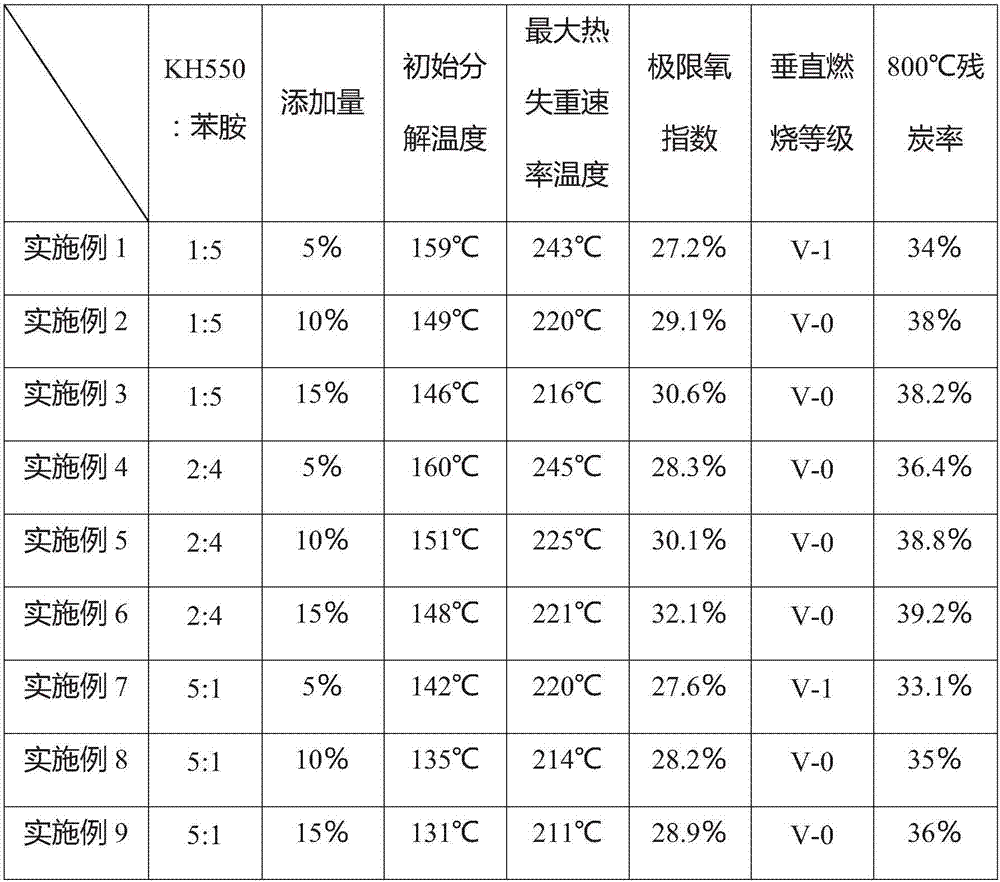

Embodiment 1

[0021] (1) Add 0.0167 mol of hexachlorocyclotriphosphazene and 40 ml of tetrahydrofuran into a three-neck flask, dissolve and stir evenly, and then add 0.0167 mol of triethylamine. N 2 Under protection, fully stirred, 0.0167mol KH550 was added dropwise to the reaction system at 0°C. The solution was heated to reflux at 40°C for 20 hours, cooled and filtered to remove triethylamine hydrochloride, and tetrahydrofuran and tetrahydrofuran were removed by rotary evaporation to obtain an oily product, which was a silanized hexachlorocyclotriphosphazene derivative.

[0022] (2) Add 0.005 mol tetrahydrofuran solution (20 ml) of silanized hexachlorocyclotriphosphazene derivative to a three-neck flask, and slowly add aniline (0.025 mol) and triethylamine tetrahydrofuran solution (0.025 mol) dropwise therein. Stir and reflux for 10 hours under the protection of nitrogen at 40°C. After the reaction, the material was cooled to room temperature, vacuum filtered, washed twice with deionized...

Embodiment 2

[0030] (1) Add 0.0167mol of hexachlorocyclotriphosphazene and 100ml of chloroform into a three-neck flask, dissolve and stir evenly, then add 0.0167mol of triethylamine. N 2 Under protection, fully stirred, 0.0167mol KH550 was added dropwise to the reaction system at 0°C. The solution was heated to reflux at 100°C for 50 hours, cooled and filtered to remove triethylamine hydrochloride, and chloroform was removed by rotary evaporation to obtain an oily substance, which was a silanized hexachlorocyclotriphosphazene derivative.

[0031] (2) Add the chloroform solution (50ml) of the hexachlorocyclotriphosphazene derivative of 0.005mol silanization in the there-necked flask, slowly drop the chloroform solution (0.025mol) of 0.025mol aniline and triethylamine therein . Stir and reflux reaction at 100°C under nitrogen protection for 20h. After the reaction, cool the material to room temperature, vacuum filter, wash with deionized water and chloroform for 5 times, and vacuum dry at ...

Embodiment 3

[0034] (1) Add 0.0167mol of hexachlorocyclotriphosphazene and 80ml of diethyl ether into a three-neck flask, dissolve and stir evenly, then add 0.0167mol of triethylamine. N 2 Stir well under protection, and drop 0.0167mol KH550 into the reaction system at 0°C. The solution was heated to reflux at 45°C for 30 hours, cooled and filtered to remove triethylamine hydrochloride, and the solvent was removed by rotary evaporation to obtain an oily product, which was a silanized hexachlorocyclotriphosphazene derivative.

[0035] (2) Add 0.005 mol of silanized hexachlorocyclotriphosphazene ethyl ether solution (30 ml) into a three-necked flask, and slowly dropwise add 0.025 mol of aniline and triethylamine solution (0.025 mol) thereinto. Stir and reflux for 15 hours under the protection of nitrogen at 45°C. After the reaction, the material was cooled to room temperature, vacuum filtered, washed with deionized water and ether three times, and vacuum-dried at 95°C for 2 hours to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com