A kind of gunning material for non-carbon ladle and its preparation method and application

A carbon-free ladle and gunning material technology, applied in the field of iron and steel smelting, can solve the problems of weak bonding performance, poor pressure resistance and high temperature bending resistance, and achieve the effects of reasonable ratio, enhanced fire resistance, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A gunning material for a carbon-free steel ladle, consisting of the following raw materials:

[0043] 5 ~ 3mm plate corundum: 20Kg; 3 ~ 1mm plate corundum: 15Kg; 1 ~ 0mm spinel: 20Kg; 325 mesh spinel: 23Kg; α-Al 2 o 3 Micropowder: 8Kg; Calcium aluminate cement: 10Kg; Explosion-proof fiber: 0.5Kg; Metal aluminum powder: 0.5Kg; Polycarboxylate anti-slump agent: 0.5Kg;

[0044] Wherein, the Al in the tabular corundum 2 o3 The content of ≥99.5%, Al in the spinel 2 o 3 The content of MgO is ≥78%, and the content of MgO is ≥21%.

[0045] The preparation process is as follows: the above-mentioned raw materials are weighed according to the formula, put into a forced stirrer and stirred evenly, and then the carbon-free ladle gunning material is obtained.

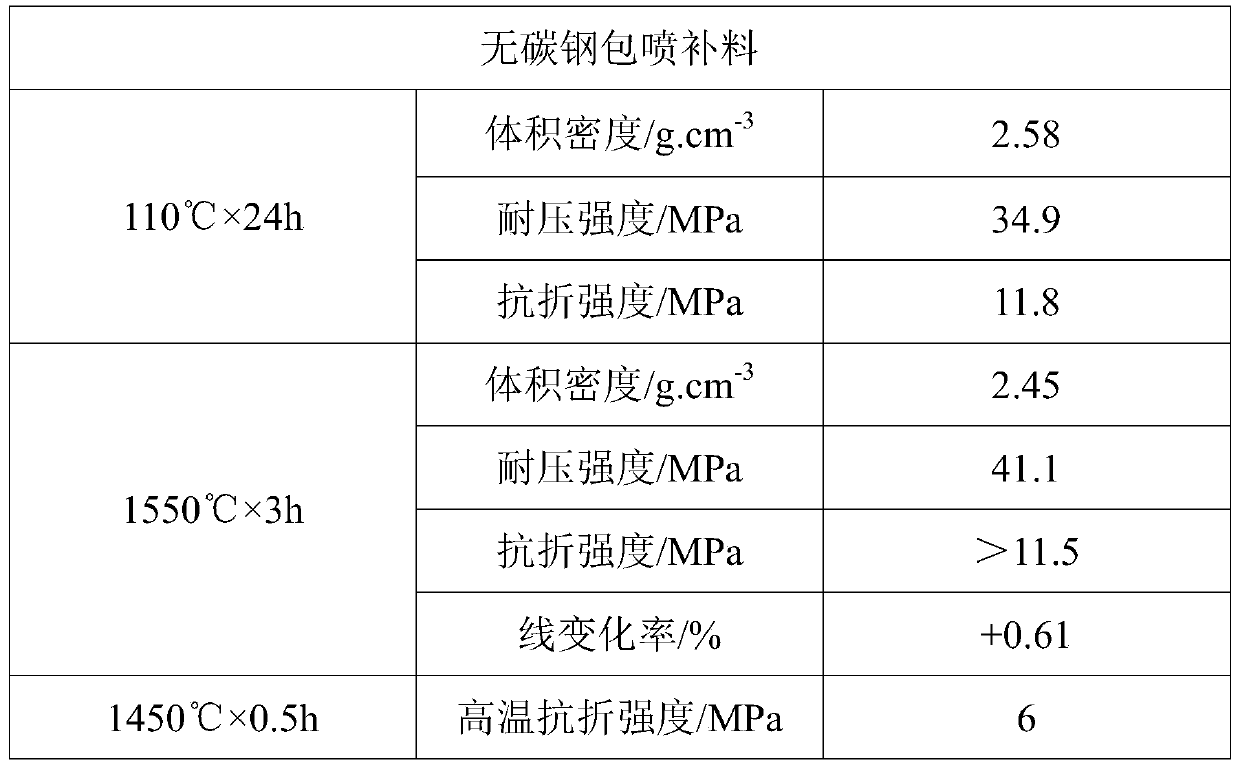

[0046] The physical and chemical indicators of the gunning material for the carbon-free ladle were detected, and the specific detection results are shown in Table 1. According to the data shown in Table 1, it can be seen...

Embodiment 2

[0051] A gunning material for a carbon-free steel ladle, consisting of the following raw materials:

[0052] 5 ~ 3mm plate corundum: 16Kg; 3 ~ 1mm plate corundum: 15Kg; 1 ~ 0mm spinel: 20Kg; 325 mesh spinel: 25Kg; α-Al 2 o 3 Micropowder: 5Kg; calcium aluminate cement: 8Kg; explosion-proof fiber: 0.08Kg; metal aluminum powder: 0.05Kg; polycarboxylate slump stabilizer: 0.05Kg;

[0053] Wherein, the Al in the tabular corundum 2 o 3 The content of ≥99.5%, Al in the spinel 2 o 3 The content of MgO is ≥78%, and the content of MgO is ≥21%.

[0054] The preparation process is as follows: the above-mentioned raw materials are weighed according to the formula, put into a forced stirrer and stirred evenly, and then the carbon-free ladle gunning material is obtained.

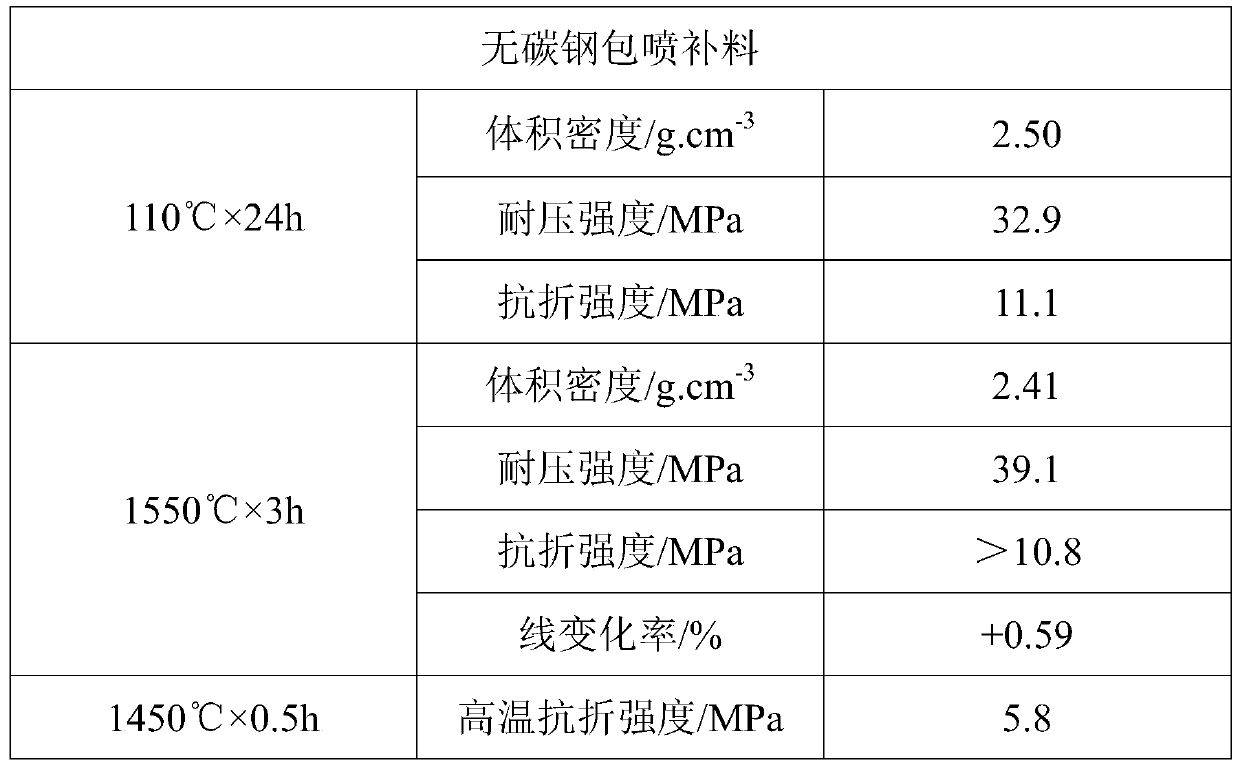

[0055] The physical and chemical indicators of the gunning material for the carbon-free ladle were detected, and the specific detection results are shown in Table 2. According to the data shown in Table 2, it can be ...

Embodiment 3

[0060] A gunning material for a carbon-free steel ladle, consisting of the following raw materials:

[0061] 5 ~ 3mm tabular alumina: 20Kg; 3 ~ 1mm tabular alumina: 15Kg; 1 ~ 0mm spinel: 25Kg; 325 mesh spinel: 20Kg; α-Al 2 o 3 Micropowder: 12Kg; Calcium aluminate cement: 10Kg; Explosion-proof fiber: 2Kg; Metal aluminum powder: 2Kg; Polycarboxylate anti-slump agent: 1Kg;

[0062] Wherein, the Al in the tabular corundum 2 o 3 The content of ≥99.5%.

[0063] The preparation process is as follows: the above-mentioned raw materials are weighed according to the formula, put into a forced stirrer and stirred evenly, and then the carbon-free ladle gunning material is obtained.

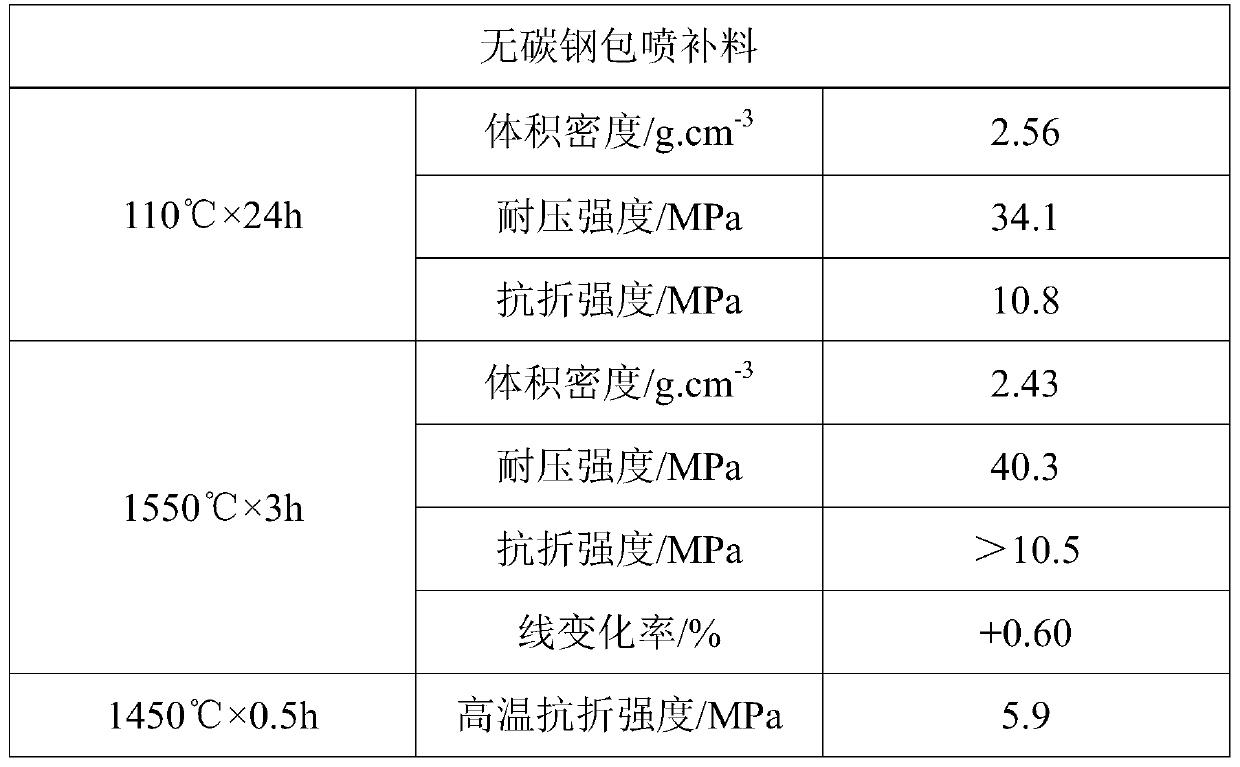

[0064] The physical and chemical indicators of the gunning material for the carbon-free ladle were detected, and the specific detection results are shown in Table 3. According to the data shown in Table 3, it can be seen that the bulk density of the gunning material described in Example 3 is suitable, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com