A kind of polycrystalline cubic boron nitride tool material and preparation method thereof

The technology of cubic boron nitride and boron nitride knife is applied in the field of polycrystalline cubic boron nitride cutting tool material and its preparation. Ultimate performance and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

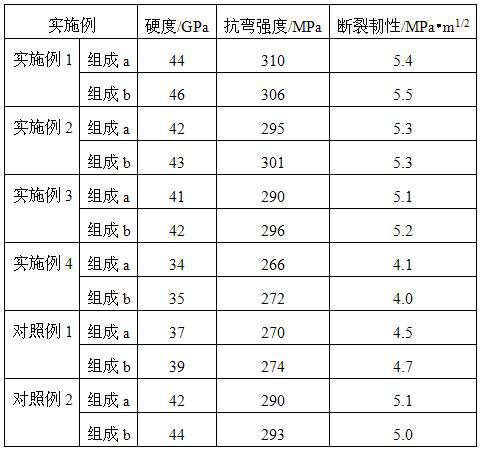

Examples

Embodiment 1

[0032] A polycrystalline cubic boron nitride cutting tool material is made of the following raw materials in weight percentage:

[0033] 70% cubic boron nitride powder, 30% binder; the particle size of the cubic boron nitride powder is 1-8 μm; the weight percentage of the binder is composed of the following composition a or composition b;

[0034] Composition a: 10% silicon powder, 5% zirconia, 0.5% ytterbium aluminum garnet, and the balance is SiC powder and Si 3 N 4 powder; among them, SiC powder and Si 3 N 4 The weight ratio of powder is 7:3;

[0035] Composition b: 3% metal powder, 7% silicon powder, 5% zirconia, 0.5% ytterbium aluminum garnet, and the balance is SiC powder and Si 3 N 4 powder; wherein, the metal powder is all Ti powder; SiC powder and Si 3 N 4 The weight ratio of powder is 7:3.

[0036] The preparation method comprises the following steps:

[0037] ① Cubic boron nitride powder treatment: Pickling cubic boron nitride powder with 15 mol / L hydrofluo...

Embodiment 2

[0042] A polycrystalline cubic boron nitride cutting tool material is made of the following raw materials in weight percentage:

[0043] 90% cubic boron nitride powder, 10% binder; the particle size of the cubic boron nitride powder is 8-15 μm; the weight percent composition of the binder is the following composition a or composition b;

[0044] Composition a: 15% silicon powder, 10% zirconia, 1% ytterbium aluminum garnet, and the balance is SiC powder and Si 3 N 4 powder; among them, SiC powder and Si 3 N 4 The weight ratio of powder is 3:7;

[0045] Composition b: 3% metal powder, 12% silicon powder, 10% zirconia, 1% ytterbium aluminum garnet, and the balance is SiC powder and Si 3 N 4 powder; wherein, half of the metal powder is Ti powder, and half is Al powder; SiC powder and Si 3 N 4 The weight ratio of powder is 3:7.

[0046] The preparation method is the same as in Example 1.

Embodiment 3

[0048] A polycrystalline cubic boron nitride cutting tool material is made of the following raw materials in weight percentage:

[0049] 80% cubic boron nitride powder, 20% binder; the particle size of the cubic boron nitride powder is 1-8 μm; the weight percentage of the binder is composed of the following composition a or composition b;

[0050] Composition a: 3% silicon powder, 20% zirconia, 5% ytterbium aluminum garnet, and the balance is SiC powder and Si 3 N 4 powder; among them, SiC powder and Si 3N 4 The weight ratio of powder is 5:5;

[0051] Composition b: 1% metal powder, 2% silicon powder, 20% zirconia, 5% ytterbium aluminum garnet, and the balance is SiC powder and Si 3 N 4 powder; wherein, the metal powder is all Al powder; SiC powder and Si 3 N 4 The weight ratio of powder is 5:5.

[0052] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com