Preparation method for foam glass with high compressive strength

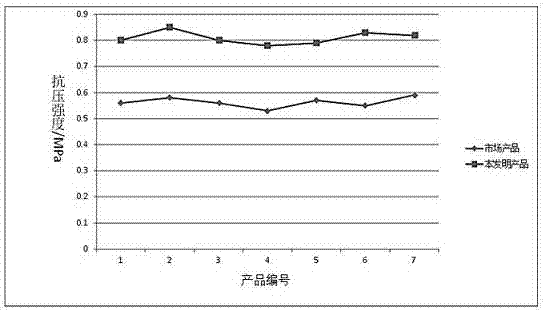

A foam glass, compressive strength technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of increasing particle grinding requirements, not improving the compressive strength of foam glass, and high production process requirements, so as to prevent Bubble breakage and bubble interconnection, promote the formation of stable bubbles, and improve the effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0021] The specific embodiment: a kind of preparation method of high compressive strength cellular glass, is finished by following steps:

[0022] (1) A method for preparing foam glass with high compressive strength. The raw materials are composed as follows: waste glass abrasive powder 90%-94%, raw material additives 1.00%-1.50%, sodium hexametaphosphate 0.5%- 2.0%, borax 1.0%~3.0%, Glauber's salt 0.4%~0.8%, calcium carbonate 1.5%~4%, foaming agent 1.8%~1.9%, foam stabilizer 0.6%~0.8%, flux 0.2%~0.4% , enhancer 0.1% ~ 0.2%.

[0023] According to the above scheme, the raw material additive is high borosilicate waste glass clinker powder, and the foaming agent is composed of 12% to 18% of limestone, 13% to 17% of magnesium carbonate, and 20% to 30% of dolomite by weight. %, activated carbon 12% to 20%, silicon carbide 2% to 6%, silicon carbonate 1% to 3%, manganese dioxide 4% to 6%.

[0024] According to the above scheme, the foam stabilizer is composed of phosphorus pentoxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com