Preparation method of biodegradable high-dust-holding-capacity air filtering material

An air filter material and biodegradable technology, which is applied in the field of preparation of biodegradable high dust holding capacity air filter materials, can solve the problems of non-biodegradability and small dust holding capacity, and achieve the promotion of biodegradability and dust holding capacity , Excellent biodegradability, and the effect of improving dust holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

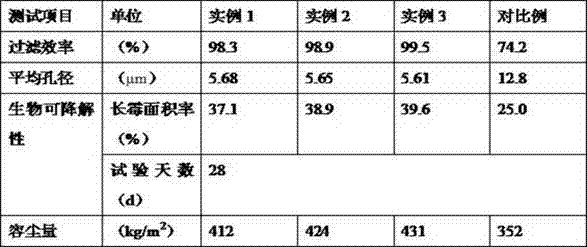

Examples

example 1

[0023] Weigh 120g of cornstarch and 60g of buckwheat starch and mix them in a fermenter with 65mL of yogurt, seal and ferment for 7 days at a temperature of 30°C, filter to remove the filter residue, then add 80mL of sulfuric acid solution with a mass fraction of 35% and mix for 16min , which is self-made lactic acid, add 25mL absolute ethanol and 14mL hydrogen peroxide with a mass fraction of 30% to the self-made lactic acid and mix, and polycondense at 30°C for 45min, which is self-made polylactic acid, which is ready for use, and the volume ratio is 1:1. Acetic anhydride and pyridine were mixed and stirred for 10 minutes to obtain a self-made mixed solution. The above-mentioned self-made polylactic acid was poured into the self-made mixed solution and mixed for 1 hour. Press and draw, that is, self-made polylactic acid fiber, weigh 0.8kg of quartz sand, grind and pulverize for 35 minutes to obtain quartz sand powder, put the quartz sand powder in a kiln at 800°C for 1 hour, ...

example 2

[0025]Weigh 140g of cornstarch and 70g of buckwheat starch and mix them in a fermenter with 75mL of yogurt, seal and ferment at 35°C for 8 days, filter to remove the filter residue, then add 90mL of sulfuric acid solution with a mass fraction of 35% and mix for 18min , which is self-made lactic acid, add 35mL absolute ethanol and 16mL hydrogen peroxide with a mass fraction of 30% to the self-made lactic acid and mix, and polycondense at 40°C for 42min, that is, self-made polylactic acid, which is ready for use, and the volume ratio is 1:1. Acetic anhydride and pyridine were mixed and stirred for 11 minutes to obtain a self-made mixed solution. The above-mentioned self-made polylactic acid was poured into the self-made mixed solution and mixed for 1.5 hours. Extrusion and drawing, that is, self-made polylactic acid fiber, weighing 1.0kg of quartz sand, grinding and pulverizing for 50 minutes, to obtain quartz sand powder, putting the quartz sand powder in a kiln at 1000 ° C for ...

example 3

[0027] Weigh 160g of cornstarch and 80g of buckwheat starch and mix them in a fermenter with 85mL of yogurt, seal and ferment at 40°C for 9 days, filter to remove the filter residue, then add 100mL of sulfuric acid solution with a mass fraction of 35% and mix for 20min , which is self-made lactic acid, add 45mL absolute ethanol and 18mL hydrogen peroxide with a mass fraction of 30% to the self-made lactic acid and mix, and polycondense at 50°C for 60 minutes, which is self-made polylactic acid, which is ready for use, and the volume ratio is 1:1. Acetic anhydride and pyridine were mixed and stirred for 12 minutes to obtain a self-made mixed solution. The above-mentioned self-made polylactic acid was poured into the self-made mixed solution and mixed for 2 hours. Press and draw, that is, self-made polylactic acid fiber. Weigh 1.2kg of quartz sand and grind it for 65 minutes to obtain quartz sand powder. Put the quartz sand powder in a kiln at 1200°C for 2 hours to melt to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com