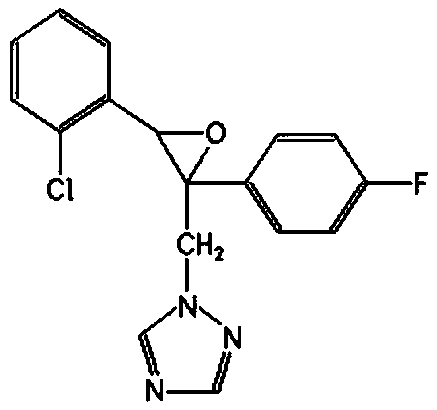

Flueconazole suspension concentrate and preparation method thereof

A technology of epoxiconazole and suspending agent, which is applied in the field of epoxiconazole suspending agent and its preparation, can solve the problems of low suspension rate and poor suspension stability, and achieve the effects of high suspension rate, prevention of aggregation, and long-term storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

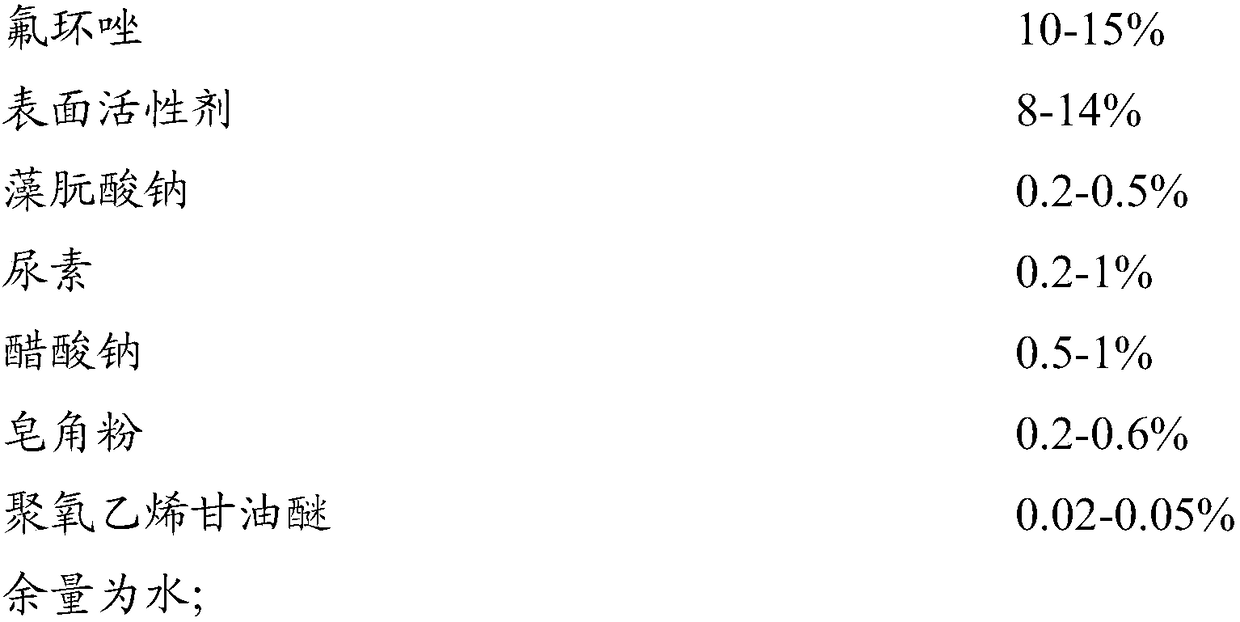

Embodiment 1

[0033] (1) According to the formula of Example 1 in Table 1, epoxiconazole, sucrose fatty acid ester, sodium tridecyl sulfosuccinate, sodium alginate, urea, sodium acetate, saponin powder, polyoxyethylene Glycerin ether and water are stirred and mixed to form a slurry, which is pulverized in a ball mill.

[0034] (2) Put it in a grinder for ultrafine pulverization, and control the average particle size to 2-4 μm.

[0035] (3) Homogenize in a homogenizer to homogenize the particles.

[0036] The prepared suspending agent is a viscous and homogeneous liquid in appearance, and its average particle diameter (D50) is 2.4 μm as measured by a Malvern laser particle size distribution analyzer.

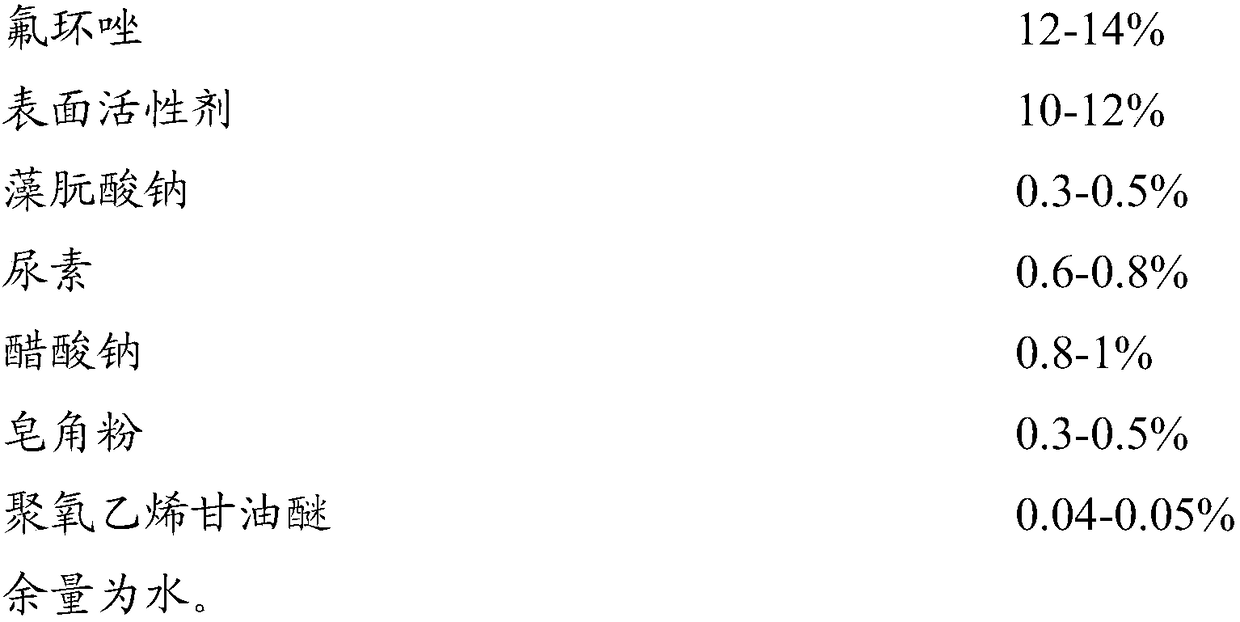

[0037] Table 1: Formulation of epoxiconazole suspension concentrate Unit: kg

[0038]

Embodiment 2

[0040] The raw materials were weighed according to the data in Table 1 corresponding to Example 2, and prepared according to the method of Example 1.

[0041] The prepared suspending agent is a viscous and homogeneous liquid in appearance, and its average particle diameter (D50) is 2.4 μm as measured by a Malvern laser particle size distribution analyzer.

Embodiment 3

[0043] The raw materials were weighed according to the data corresponding to Example 3 in Table 1, and prepared according to the method of Example 1.

[0044] The prepared suspending agent is a viscous and homogeneous liquid in appearance, and its average particle diameter (D50) is 2.3 μm as measured by a Malvern laser particle size distribution analyzer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com