Fabrication method for flexible printed circuit (FPC) fine circuit

A production method and fine circuit technology, applied in the manufacture of printed circuits, removal of conductive materials by chemical/electrolytic methods, printed circuits, etc., can solve problems such as high defect rate of circuits, dry film peeling off, dry film easy to fall off, etc., to achieve Simple and scientific design, reduced dry film shedding, and good copper surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

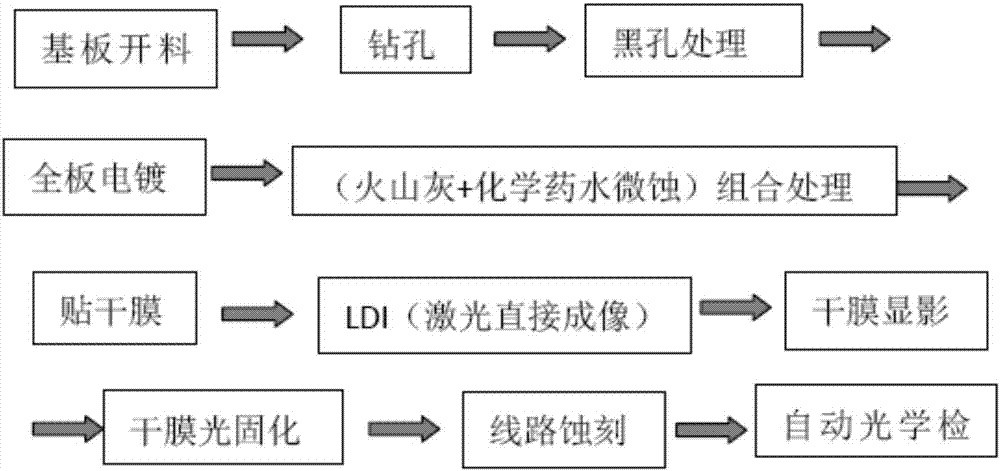

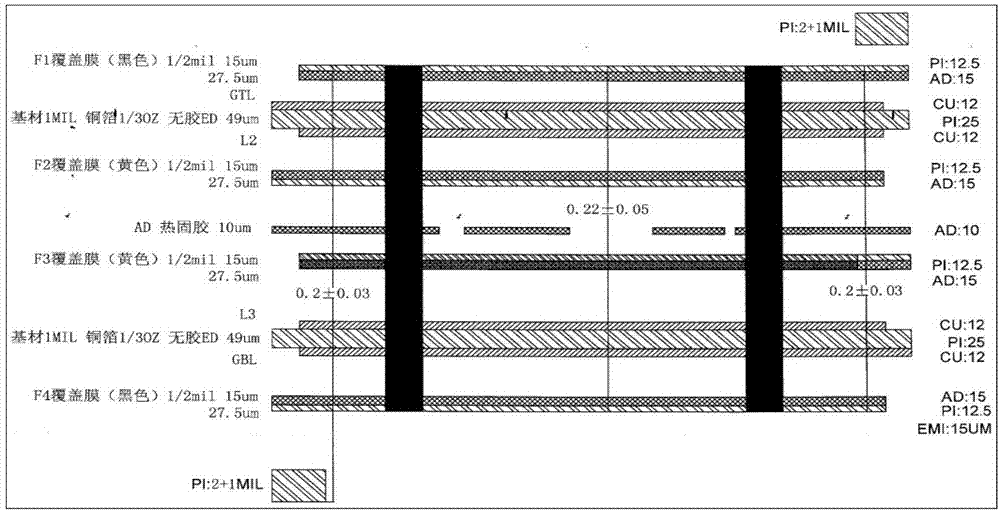

[0030] Such as figure 1 and figure 2 As shown, a FPC fine circuit (30μm / 30μm) manufacturing method:

[0031] 1. Substrate cutting: control the thickness of polyimide (PI) copper to 8 μm to 12 μm, and the laser power of laser cutting is ≥6W.

[0032] 2. Laser drilling: the minimum drilling diameter is 0.05mm-0.1mm, the energy of the laser drilling machine is 4.2-4.5w, the frequency is 40kHz, and the drilling speed is 320-350mm / s.

[0033] 3. Black hole treatment: micro-etching: SPS concentration 60g / L~90g / L, H 2 SO 4 Concentration mass fraction is 3%, Cu 2+ Concentration ≤ 24g / L; ultrasonic cleaning: equivalent concentration of cleaning solution 0.25N-0.30N, ultrasonic cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com