Liquid oxygen and fuel oil mixing device

A mixing device and liquid oxygen technology, applied in mixers, liquid carbon-containing fuels, fuels, etc., can solve the problems of astonishing energy waste and low utilization rate of thermal efficiency of engines, so as to improve the utilization rate of thermal efficiency and solve the problem of low utilization rate of thermal efficiency, The effect of scientific and simple device design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

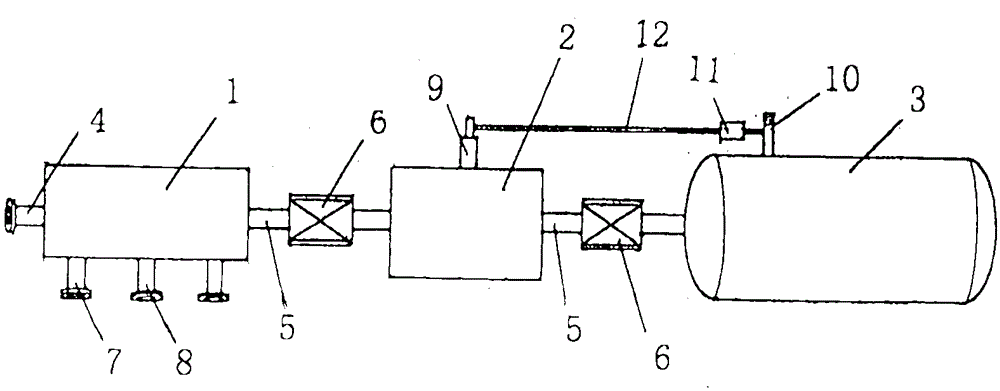

[0009] figure 1 As shown: the tail of the Laval tube 1 provided with the compressed air intake pipe 4 is connected to the pressurization chamber 2 through the delivery pipe 5 and then connected to the energy storage tank 3, and the delivery pipes 5 connected to the two ends of the pressurization chamber 2 are respectively installed with inverters. One-way check valve 6, liquid fuel suction pipe 7 and liquid oxygen suction pipe 8 are arranged on one side of Laval tube 1, electronic spark plug 9 is installed above booster chamber 2, and pressure sensor is installed on barometer pipe joint 10 above energy storage tank 3 11 is connected with electronic spark plug 9 by wire 12.

[0010] The working principle of the present invention is as follows: when the compressed gas enters the Laval tube 1 through the intake pipe 4, it drives the Laval tube 1 liquid fuel suction pipe 7 and the liquid oxygen suction pipe 8 to suck fuel and liquid oxygen into the pipe and mix them. The gas mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com