A kind of preparation method of high-efficiency denitration catalyst

A technology of denitrification catalyst and sodium hydroxide, which is applied in the field of preparation of denitrification catalyst and denitrification catalyst, can solve the problems of high production cost and hinder application, and achieve the effect of increasing added value, easy enlargement and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

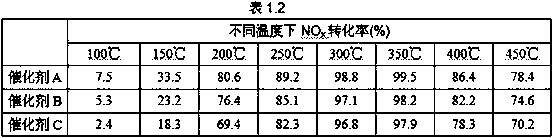

Image

Examples

Embodiment 1

[0022] 1) Copper slag pretreatment: crush the copper slag, screen out 80-100 mesh copper slag, put it in a sodium hydroxide solution with a mass concentration of 15%, then stir it at room temperature for 8 hours and then filter it. After the copper slag is filtered and washed to neutral, it is dried at 105°C for 12 hours; the dried copper slag is placed in a heating device, and 25% O 2 +75%N 2 In a circulating atmosphere, the temperature was raised from room temperature to 500 °C at a rate of 1 °C / min, and it was naturally lowered to room temperature after 5 hours of heat preservation; the mass-volume ratio of copper slag and sodium hydroxide solution was 0.2 g / mL,

[0023] 2) Copper slag modification: Weigh 100g of sucrose and dissolve it in 200mL of deionized water and stir it at room temperature to completely dissolve to obtain a sucrose solution; then add 100g of the copper slag obtained in step 1) to the sucrose solution and continue stirring 8min to obtain mixture A; tr...

Embodiment 2

[0027] 1) Copper slag pretreatment: crush the copper slag, screen out 80-100 mesh copper slag, place it in a sodium hydroxide solution with a mass concentration of 25%, then stir it at room temperature for 4 hours and then filter it. After the copper slag is filtered and washed to neutral, it is dried at 105°C for 12 hours; the dried copper slag is placed in a heating device, and 25% O 2 +75%N 2 In a circulating atmosphere, the temperature was raised from room temperature to 500 °C at a rate of 1 °C / min, and it was naturally lowered to room temperature after 5 hours of heat preservation; wherein, the mass-volume ratio of copper slag and sodium hydroxide solution was 0.4 g / mL;

[0028] 2) Modification of copper slag: Weigh 100g of sucrose and dissolve it in 200mL of deionized water and stir at room temperature for 20min to completely dissolve to obtain a sucrose solution; then add 100g of copper slag obtained in step 1) to the sucrose solution and continue stirring After 10 mi...

Embodiment 3

[0032] 1) Copper slag pretreatment: crush the copper slag, screen out 80-100 mesh copper slag and place it in a sodium hydroxide solution with a mass concentration of 20%, wherein the mass-volume ratio of copper slag and sodium hydroxide solution is 0.3 g / mL, stirred at room temperature for 6 hours, then filtered, filtered and washed the filtered copper slag until neutral, and dried at 105°C for 12 hours; then put the dried copper slag in a heating device, 25% O 2 +75%N 2 In a circulating atmosphere, the temperature was raised from room temperature to 500 °C at a rate of 1 °C / min, and it was naturally lowered to room temperature after 5 hours of heat preservation;

[0033] 2) Copper slag modification: Weigh 100% of sucrose, dissolve it in 200mL deionized water and stir at room temperature for 15 minutes to completely dissolve to obtain a sucrose solution, then add the copper slag obtained in step 1) to the sucrose solution, and continue stirring Treat for 12 minutes to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com