Synthesis method of FeS2 composite positive electrode material, and battery

A composite positive electrode material and synthesis method technology, applied in the field of synthesis of FeS2 composite positive electrode materials, can solve the problems of high open circuit voltage, hindrance to industrialization development, low discharge performance, etc., and achieve the effects of prolonging life, facilitating transmission, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

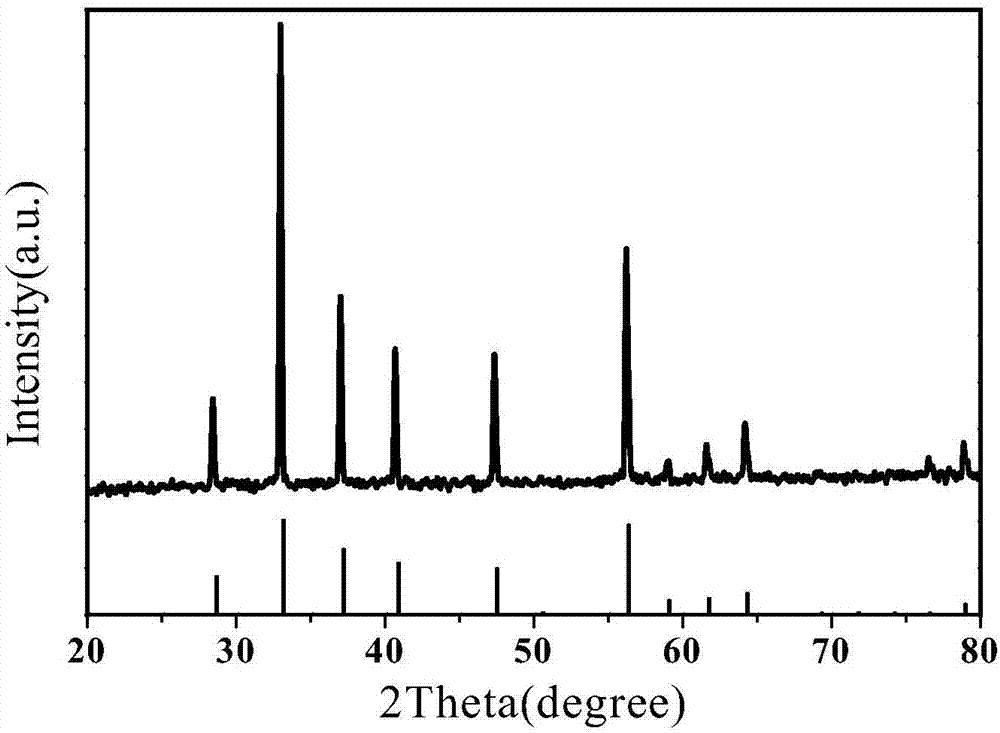

Image

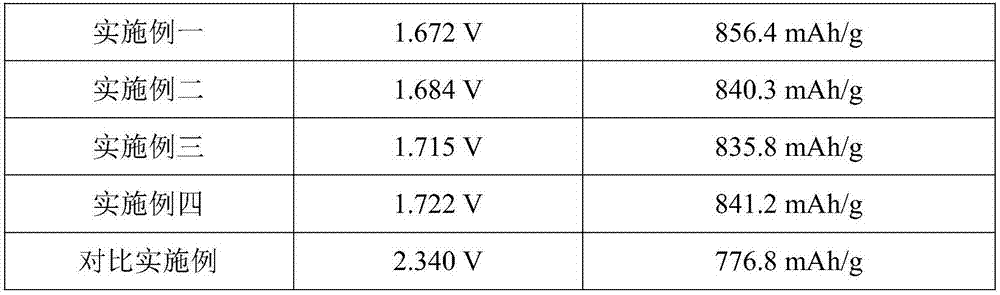

Examples

Embodiment 1

[0025] Embodiment one: a kind of FeS 2 Composite positive electrode material, the composite positive electrode material is coated with FeS by metal powder 2 powder, where the FeS 2 The mass percentage content of the powder is 98%, the mass percentage content of the metal powder is 2%, and the metal powder is zinc powder.

[0026] Its preparation steps are as follows:

[0027] (1) Weighing 1.44g of ferrous oxalate, 3g of thiourea and 0.03g of PVP was dissolved in 50mL of deionized water to form a mixed solution;

[0028] (2) Stir the mixed solution at a constant temperature in a water bath at 60° C. for 1 hour, then add 3.72 g of disodium EDTA and 0.96 g of sulfur powder, keep stirring, adjust the pH of the solution to 7 with ammonia water, and form a sol;

[0029] (3) After the sol is formed, it is heated to 70° C. and stirred for 3 hours to obtain a wet gel, which is dried at 120° C. under vacuum for 8 hours to obtain a dry gel;

[0030] (4) Place the obtained xerogel in ...

Embodiment 2

[0035] Embodiment two: a kind of FeS 2 Composite positive electrode material, the composite positive electrode material is coated with FeS by metal powder 2 powder, where the FeS 2 The mass percentage content of the powder is 98%, the mass percentage content of the metal powder is 2%, and the metal powder is copper powder.

[0036] Its preparation steps are as follows:

[0037] (1) Take by weighing 2.68g of ferrous citrate, 1.5g of thiourea and 0.027g of PVP dissolved in 50mL of deionized water to form a mixed solution;

[0038] (2) Stir the mixed solution at a constant temperature in a 55°C water bath for 0.5h, then add 3.84g of citric acid and 1.28g of sulfur powder, keep stirring, adjust the pH of the solution to 7.5 with ammonia water, and form a sol;

[0039] (3) After the sol is formed, it is heated to 80° C. and stirred for 2 hours to obtain a wet gel, which is dried at 140° C. under vacuum for 6 hours to obtain a dry gel;

[0040] (4) Place the obtained xerogel in ...

Embodiment 3

[0044] Embodiment three: a kind of FeS 2 Synthesis method and battery of composite positive electrode material, the composite positive electrode material is coated with FeS by metal powder 2 powder, where the FeS 2 The mass percentage content of the powder is 98%, the mass percentage content of the metal powder is 2%, and the metal powder is silver powder.

[0045] Its preparation steps are as follows:

[0046] (1) Take by weighing 1.74g of ferrous acetate, 2.25g of thiourea and 0.02g of PVP dissolved in 50mL of deionized water to form a mixed solution;

[0047] (2) Stir the mixed solution at a constant temperature in a water bath at 50° C. for 1 hour, then add 3.72 g of disodium EDTA and 0.16 g of sulfur powder, keep stirring, adjust the pH of the solution to 8 with ammonia water, and form a sol;

[0048] (3) After the sol is formed, heat it up to 75°C and stir for 2.5 hours to obtain a wet gel, and dry the obtained wet gel at 130°C under vacuum for 10 hours to obtain a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com