Preparation method of high-chromium vanadium-titanium magnetite pellets

A technology of vanadium-titanium magnetite and vanadium-titanium magnet, which is applied in the field of preparation of high-chromium vanadium-titanium magnetite pellets, which can solve the problems of large fluctuations in the humidity of the mixture, long drying time of the pellets, and long roasting time of the pellets, etc. problems, to achieve the effect of small water loss, shortened drying time, and small water evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

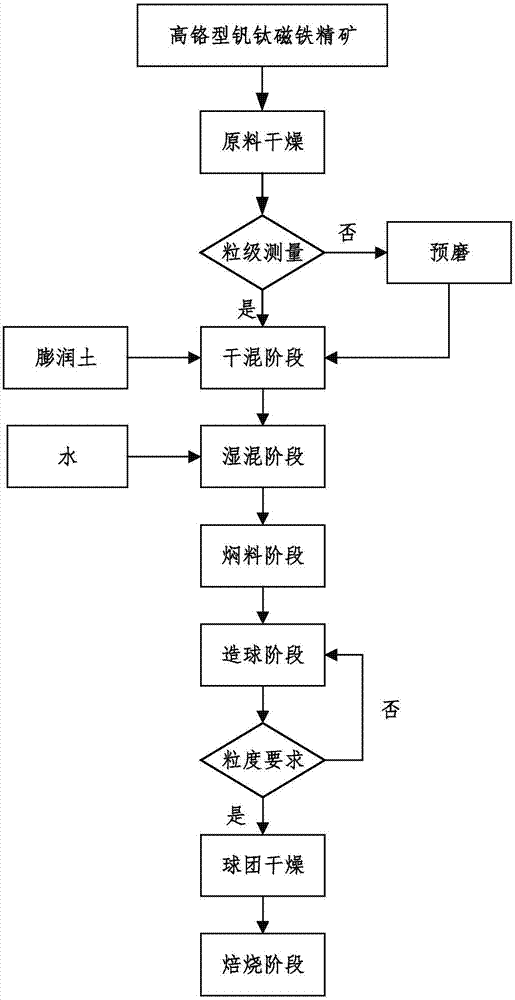

[0046] A preparation method of high-chromium vanadium-titanium magnetite pellets, reference figure 1 As shown, the method includes:

[0047] 1. Raw material drying

[0048] The high-chromium vanadium-titanium magnetite is dried in a drying box, the drying temperature is 105-108 DEG C, and the drying time is 4 to 4.5h, so that the moisture of the high-chromium-type vanadium-titanium magnetite is less than or equal to 1.4%.

[0049] It has been tested that the moisture content of the high-chromium vanadium-titanium magnetite powder is in the range of 1.2% to 1.4%, which is the crystal water content, and the content exceeding this range is free water; to avoid free water from affecting the dry mixing effect, such as bentonite absorbing high-chromium vanadium The moisture in the titanomagnetite will agglomerate together and reduce the mixing effect with the high-chromium vanadium-titanium magnetite; at the same time, to ensure precise adjustment of the moisture content during the wet mix...

Embodiment 2

[0075] A method for preparing high-chromium vanadium-titanium magnetite pellets. This example is based on Example 1. The specific operation steps are as follows:

[0076] 1. Raw material drying

[0077] Take 5kg of high-chromium vanadium-titanium magnetite and dry it in a drying box. The drying temperature is 108℃ and the drying time is 4h. After drying, the moisture content of the high-chromium-type vanadium-titanium magnetite is 1.2%. .

[0078] 2. Mixing stage

[0079] The calcium-based bentonite is added to the high-chromium-type vanadium-titanium magnetite for dry mixing treatment, and the dry-mixing time is 10 minutes. The calcium-based bentonite added accounts for 0.9% of the weight of the high-chromium-type vanadium-titanium magnetite.

[0080] The high-chromium vanadium-titanium magnetite is then sprayed and wet-mixed, wherein the water is evenly sprayed onto the dry-mixed high-chromium-type vanadium-titanium magnetite through a high-pressure sprayer, and the wet-mixing treatm...

Embodiment 3

[0093] This embodiment is based on embodiment 1, and the specific operations are as follows:

[0094] 1. Raw material drying

[0095] Take 5kg of high-chromium vanadium-titanium magnetite and dry it in a drying box. The drying temperature is 106℃ and the drying time is 4.5h. After drying, the water content of the high-chromium-type vanadium-titanium magnetite is 1.22. %.

[0096] 2. Mixing stage

[0097] The hydrogen-based bentonite is added to the high-chromium-type vanadium-titanium magnetite for dry mixing treatment, and the dry-mixing time is 12 minutes, and the calcium-based bentonite added therein accounts for 1.1% of the weight of the high-chromium-type vanadium-titanium magnetite.

[0098] The high-chromium vanadium-titanium magnetite is then sprayed and wet-mixed, wherein the water is evenly sprayed onto the dry-mixed high-chromium-type vanadium-titanium magnetite through a high-pressure sprayer, and the wet-mixing treatment is performed by spraying water while mixing. The am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com