Method for reducing erosion of Al2O3-C stopper during pouring of aluminum killed cold heading steel

A technology of cold heading steel and al2o3-c, which is applied in the direction of casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve the problems of aluminum-killed cold heading steel corrosion, etc., reduce the consumption of aluminum wires, reduce the cost per ton of steel, Effect of avoiding stopper rod erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

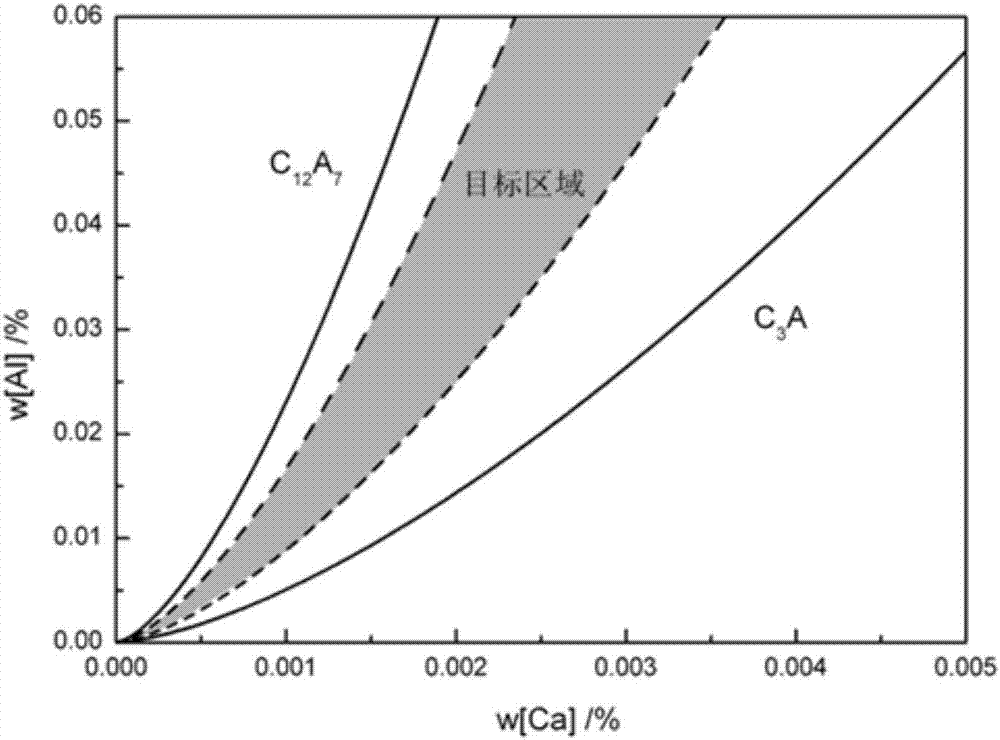

[0031] Now choose the steel type as cold heading steel as SWRCH22AB as an example to illustrate.

[0032] The molten steel tapped from the SWRCH22AB converter enters the LF refining station to start refining. By adding lime, calcium carbide and other slag materials to make white slag, adding alloys such as ferromanganese, adjusting the flow rate of bottom-blown argon, feeding aluminum wire, feeding calcium wire and other process steps to Complete the refining tasks such as desulfurization, adjustment of molten steel [Al] and [Ca], adjustment of temperature, and removal of inclusions. When LF refining and tapping, the [Al] in molten steel is 0.030%, 4.5×10 -6 , when the tundish is poured, the full protection pouring is used, and the Al 2 O 3 -C quality integral stopper rod to control the flow rate of molten steel during the pouring process. Al used in the tundish to protect the pouring process 2 O 3 -Al in quality C monolithic stopper rod 2 O 3 The mass percentage is 58...

Embodiment 2

[0035] Now choose the steel type as cold heading steel as SWRCH22AB as an example to illustrate.

[0036] The molten steel tapped from the SWRCH22AB converter enters the LF refining station to start refining. By adding lime, calcium carbide and other slag materials to make white slag, adding ferromanganese and other alloys, adjusting the flow of argon gas at the bottom, feeding aluminum wire, feeding calcium wire and other process steps to Complete the refining tasks such as desulfurization, adjustment of molten steel [Al] and [Ca], adjustment of temperature, and removal of inclusions. When LF refining and tapping, the [Al] in molten steel is 0.039%, 7.8×10 -6 , when the tundish is poured, the full protection pouring is used, and the Al 2 O 3 -C quality integral stopper rod to control the flow rate of molten steel during the pouring process. Al used in the tundish to protect the pouring process 2 O 3 -Al in quality C monolithic stopper rod 2 O 3 The mass percentage is 60...

Embodiment 3

[0039] Now choose the steel type as cold heading steel as SWRCH22AB as an example to illustrate.

[0040] The molten steel tapped from the SWRCH22AB converter enters the LF refining station to start refining. By adding lime, calcium carbide and other slag materials to make white slag, adding ferromanganese and other alloys, adjusting the flow of argon gas at the bottom, feeding aluminum wire, feeding calcium wire and other process steps to Complete the refining tasks such as desulfurization, adjustment of molten steel [Al] and [Ca], adjustment of temperature and removal of inclusions. When LF refining and tapping, the [Al] in molten steel is 0.045%, is 10×10 -6 , when the tundish is poured, the full protection pouring is used, and the Al 2 O 3 -C quality integral stopper rod to control the flow rate of molten steel during the pouring process. Al used in the tundish to protect the pouring process 2 O 3 -Al in quality C monolithic stopper rod 2 O 3 The mass percentage is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com