Natural zeolite multifunctional modification method for improving ammonia nitrogen removal rate of water body

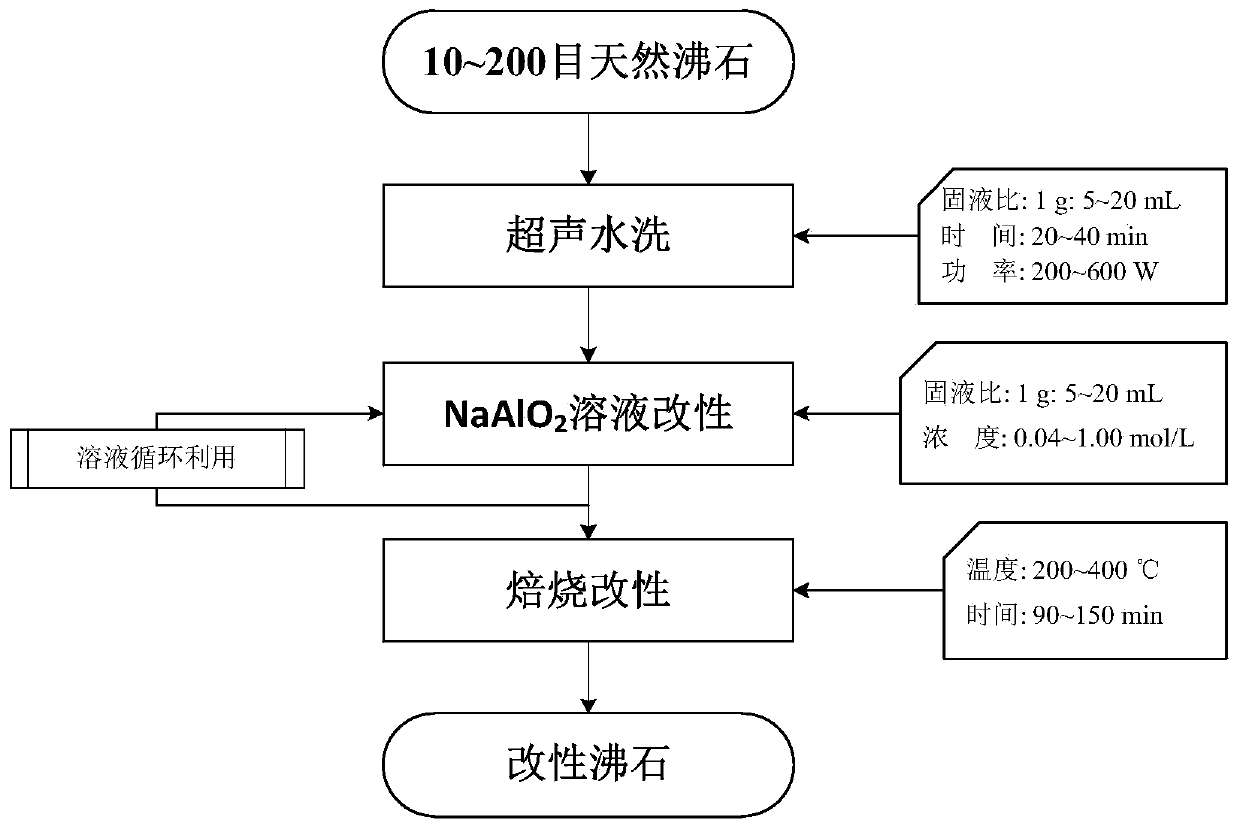

A technology of ammonia nitrogen removal rate and natural zeolite, which is applied in the field of multifunctional modification of natural zeolite, can solve problems such as damage, secondary pollution, and waste of resources, and achieve the effects of improving ion exchange capacity, sufficient modification, and reducing the ratio of silicon to aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The natural zeolite is crushed and sieved to obtain zeolite particles with a mesh size of 20-50 mesh. Ultrasonic cleaning was performed for 20 minutes under the conditions of a power of 300W and a solid-to-liquid ratio of zeolite to water of 1g:20mL. Mix the pretreated zeolite with 0.20mol / L sodium metaaluminate solution at a solid-to-liquid ratio of 1g:10mL, and impregnate and modify for 20h. After solid-liquid separation, the zeolite is dried at 105° C., and then calcined at 300° C. for 150 minutes to obtain a multifunctional modified zeolite. The zeolite modified by this method has a removal rate of 60.53% for ammonia nitrogen.

Embodiment 2

[0036] The natural zeolite is crushed and sieved to obtain zeolite particles with a mesh size of 20-50 mesh. Ultrasonic cleaning was performed for 10 minutes at a power of 360W and a solid-to-liquid ratio of zeolite to water of 1g:20mL. Mix the pretreated zeolite with 0.10mol / L sodium metaaluminate solution at a solid-to-liquid ratio of 1g:20mL, and impregnate and modify for 20h. After solid-liquid separation, the zeolite is dried at 105° C., and then calcined at 200° C. for 120 minutes to obtain a multifunctional modified zeolite. The zeolite modified by this method has a removal rate of 59.67% for ammonia nitrogen.

Embodiment 3

[0038] The natural zeolite is crushed and sieved to obtain zeolite particles with a mesh size of 20-50 mesh. Ultrasonic cleaning was performed for 30 minutes at a power of 480W and a solid-to-liquid ratio of zeolite to water of 1g:20mL. Mix the pretreated zeolite with 0.50mol / L sodium metaaluminate solution at a solid-to-liquid ratio of 1g:20mL, and impregnate and modify for 24h. After solid-liquid separation, the zeolite is dried at 105° C., and then calcined at 300° C. for 120 minutes to obtain a multifunctional modified zeolite. The zeolite modified by this method has a removal rate of 66.75% for ammonia nitrogen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com