A method for preparing sulfur- and nitrogen-doped carbon quantum dots through separation on a column and applications

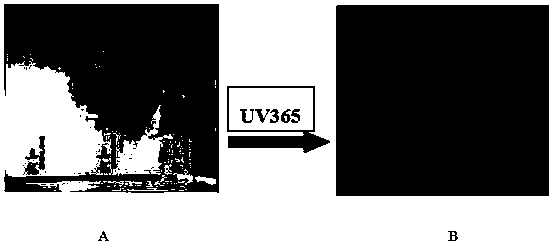

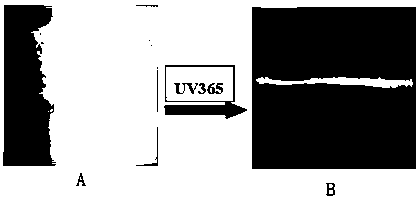

A technology of carbon quantum dots and nitrogen doping, applied in the field of chemical analysis and detection, can solve the problems of limiting the application of carbon quantum dots, incompatibility with organic solvents to form anti-counterfeiting ink, etc., and achieves easy identification, easy anti-counterfeiting processing, high fluorescence characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation of sulfur- and nitrogen-doped carbon quantum dot solution: Weigh 10 g of poly(sodium p-styrene sulfonate) and 5 g of o-phenylenediamine, add it to 500 mL of ultrapure water, and sonicate for 10 min to form a colorless and transparent solution. It was transferred to a polytetrafluoroethylene reactor, heated at 220 °C for 10 hours, and after natural cooling, it was first filtered with a 0.22 μm filter membrane, and then dialyzed with a dialysis bag with a molecular weight cut-off of 3500 Da for 24 hours to obtain water-soluble sulfur and nitrogen doped Heterofluorescent carbon quantum dots;

[0028] 2. Separation of carbon quantum dots:

[0029] (1) Wet packing: 15g of 200-300 mesh silica gel is mixed with 75mL of ethyl acetate, ultrasonicated for 5min, and stirred continuously to remove air bubbles, and packed in a chromatographic column with an inner diameter of 24mm, and the height of the silica gel column is about 10cm;

[0030] (2) Sample loading: The...

Embodiment 2

[0036] 1. Preparation of sulfur and nitrogen doped carbon quantum dot solution: Weigh 15g of poly(sodium p-styrene sulfonate) and 8g of o-phenylenediamine, add it to 500mL of ultrapure water, and ultrasonicate for 15min to form a colorless and transparent solution. It was transferred to a polytetrafluoroethylene reaction kettle, heated at 250 °C for 10 hours, and after natural cooling, it was first filtered with a 0.22 μm filter membrane, and then dialysis treatment was carried out with a dialysis bag with a molecular weight cut-off of 3000 Da for 24 hours to obtain water-soluble sulfur and nitrogen doped Heterofluorescent carbon quantum dots;

[0037] 2. Separation of carbon quantum dots:

[0038] (1) Mix 15g of 200-300 mesh silica gel with 105mL of ethyl acetate, sonicate for 10min, and keep stirring to remove air bubbles, and pack it into a 24mm inner diameter chromatography column;

[0039] (2) Sample loading: The water-soluble sulfur and nitrogen-doped fluorescent carbon...

Embodiment 3

[0046] 1. Preparation of sulfur- and nitrogen-doped carbon quantum dot solution: Weigh 12 g of poly(sodium p-styrene sulfonate) and 10 g of o-phenylenediamine, add it to 500 mL of ultrapure water, and ultrasonicate for 12 minutes to form a colorless and transparent solution. It was transferred to a polytetrafluoroethylene reactor, heated at 230°C for 10h, and after natural cooling, filtered with a 0.22μm filter membrane, and then dialysis treatment with a dialysis bag with a molecular weight cut-off of 3200Da for 24h to obtain water-soluble sulfur, nitrogen-doped Heterofluorescent carbon quantum dots;

[0047] 2. Separation of carbon quantum dots:

[0048] (1) Mix 15g of 200-300 mesh silica gel with 150mL of ethyl acetate, sonicate for 8min, and keep stirring to remove air bubbles, and pack into a 24mm inner diameter chromatography column;

[0049] (2) Sample loading: The water-soluble sulfur- and nitrogen-doped fluorescent carbon quantum dot solution was first vacuum-dried a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com