Application method of ultraviolet curing adhesive for temporary protection

A technology of temporary protection and application method, applied in the direction of adhesive, bonding method, adhesive type, etc., can solve the problem of easy falling off of rubber stopper, and achieve the effect of improving product quality, low hardness and high curing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

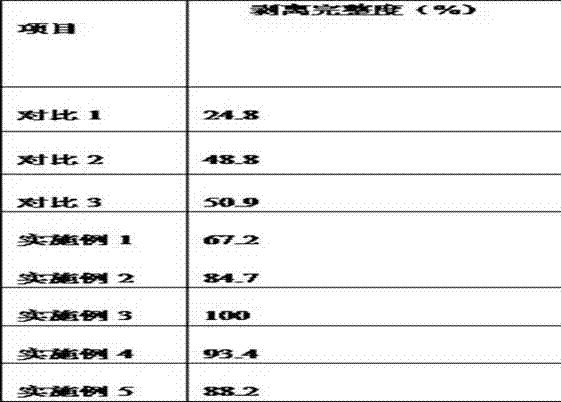

Examples

Embodiment 1

[0048] Put the UV-curable adhesive into the opaque needle tube, install the needle, put the needle tube with the needle into the automatic dispensing machine, set the dispensing program according to the dispensing path, control the air pressure at 60psi, and glue the glue during CNC processing The glue is injected into the corresponding screw hole of the metal shell, and the UV-curable adhesive is completely cured by natural light irradiation or artificial ultraviolet light irradiation; after the CNC treatment, the second ultraviolet light irradiation is performed to peel off the rubber plug in the screw hole;

[0049] Described ultraviolet curing adhesive is carried out according to the following steps:

[0050] 40 parts of self-made bifunctional urethane acrylate prepolymer, 10 parts of multifunctional urethane acrylate prepolymer, 8 parts of polyester acrylate prepolymer, 12 parts of reactive amine complexing agent, acrylate reactive diluent 20 parts, 2 parts of leveling we...

Embodiment 2

[0057] Put the UV-curable adhesive into the opaque needle tube, install the needle, put the needle tube with the needle into the automatic dispensing machine, set the dispensing program according to the dispensing path, control the air pressure at 60psi, and glue the glue during CNC processing The glue is injected into the corresponding screw hole of the metal shell, and the UV-curable adhesive is completely cured by natural light irradiation or artificial ultraviolet light irradiation; after the CNC treatment, the second ultraviolet light irradiation is performed to peel off the rubber plug in the screw hole;

[0058] Described ultraviolet curing adhesive is carried out according to the following steps:

[0059] The ultraviolet curing glue is carried out according to the following steps:

[0060] 40 parts of self-made bifunctional urethane acrylate prepolymer, 10 parts of multifunctional urethane acrylate prepolymer, 8 parts of polyester acrylate prepolymer, 12 parts of react...

Embodiment 3

[0067] Put the UV-curable adhesive into the opaque needle tube, install the needle, put the needle tube with the needle into the automatic dispensing machine, set the dispensing program according to the dispensing path, control the air pressure at 60psi, and glue the glue during CNC processing The glue is injected into the corresponding screw hole of the metal shell, and the UV-curable adhesive is completely cured by natural light irradiation or artificial ultraviolet light irradiation; after the CNC treatment, the second ultraviolet light irradiation is performed to peel off the rubber plug in the screw hole;

[0068] Described ultraviolet curing adhesive is carried out according to the following steps:

[0069] 20-60 parts of self-made bifunctional urethane acrylate prepolymer, 5-15 parts of multi-functional urethane acrylate prepolymer, 5-15 parts of polyester acrylate prepolymer, 5-20 parts of reactive amine complexing agent 10-30 parts of acrylate reactive diluent, 0.5-5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com