High-intensity high-temperature-resistant polymer-based dielectric thin film and preparation method thereof

A high-temperature-resistant polymer and dielectric film technology, which can be applied to flat products, other household appliances, household appliances, etc., can solve problems such as interfacial compatibility that is prone to agglomeration, high glass transition temperature, and poor heat resistance. Achieve the effect of improving mechanical strength and temperature resistance level, high dielectric constant and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Such as figure 1 As shown, the preparation method of the high-strength and high-temperature-resistant polymer-based dielectric film provided by the embodiment of the present invention includes the following steps:

[0030] S101: Grafting 4-aminophenoxyphthalonitrile (4-APN) onto the surface of graphene oxide (GO) by chemical modification;

[0031]S102: Use cyano-functionalized graphene (GN-CN) as a filler and cross-linkable polyarylether nitrile (PEN-ph) as a matrix to prepare a mixed solution, and use high-speed ball milling to obtain uniformly dispersed PEN-ph PEN-ph / GN-CN composite film with controllable thickness and size can be obtained by melting and pressing ultrafine powder of / GN-CN into film;

[0032] S103: A polymer-based dielectric composite film with comprehensive properties such as high temperature resistance, excellent mechanical and dielectric properties obtained through uniaxial thermal stretching and high-temperature crosslinking.

[0033] The prepar...

Embodiment 1

[0046] Preparation of cyano-functionalized graphene (GN-CN):

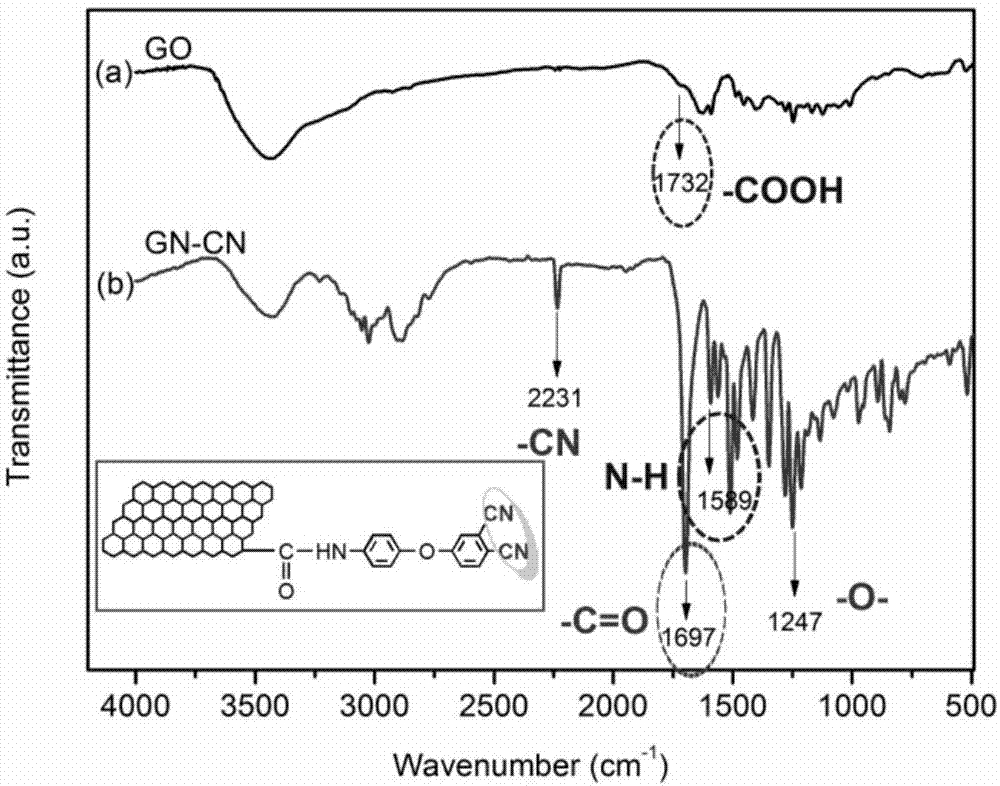

[0047] GO was put into thionyl chloride solution and stirred ultrasonically, and heated under reflux at 70°C for 24 h under the catalysis of N,N-dimethylformamide. After the reaction was completed, the thionyl chloride in the system was removed by refluxing toluene, and the obtained black reaction product was vacuum-dried to obtain acid-chlorinated graphene (GN-COCl). Then, excess 4-APN and GN-COCl were added to the toluene solvent, and the reaction was stirred and refluxed at 25°C for 72h. The reaction product obtains cyano-functionalized graphene (GN-CN) after repeated washing, centrifugation and vacuum drying, and the infrared spectrum and structural formula of GN-CN are as follows figure 2 shown.

[0048] Synthesis of crosslinkable polyarylene ether nitrile (PEN-ph):

[0049] (1) Add 34.4g of 2,6-dichlorobenzonitrile to 75mL of N-methylpyrrolidone to obtain a solution with a concentration of 0.229g / mL;

[...

Embodiment 2

[0065] Preparation of cyano-functionalized graphene (GN-CN):

[0066] The preparation of cyano-functionalized graphene (GN-CN) is consistent with the process in Example 1.

[0067] Preparation of PEN-ph / GN-CN Dielectric Film:

[0068] (1) Dissolve 4g of PEN-ph in 20mL of N-methylpyrrolidone (NMP) to obtain a PEN-ph solution with a concentration of 200mg / mL;

[0069] (2) Dissolve 80mg of GN-CN in 20mL of N-methylpyrrolidone (NMP), and stir in a water bath ultrasonically (60°C, 100W) to obtain a uniformly dispersed GN-CN solution with a concentration of 4mg / mL;

[0070] (3) Slowly add the GN-CN solution obtained in step (2) to the PEN-ph solution in step (1), and ultrasonically and mechanically stir at 60°C for 0.5-2 hours to obtain a concentration of 100 mg / mL dispersed Uniform PEN-ph / GN-CN solution, wherein the mass fraction of GN-CN in PEN-ph is 2%;

[0071] (4) Add 200mL of precipitation solution (precipitation solution is a mixture of deionized water and NMP, the volume ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Performance | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com