A kind of method for continuously synthesizing n-methylpyrrolidone and n-ethylpyrrolidone

A technology of ethylpyrrolidone and methylpyrrolidone, which is applied in the field of continuous synthesis of N-methylpyrrolidone and N-ethylpyrrolidone using micro-reaction technology, can solve the problems of high reaction pressure, high safety risk, high catalyst cost, etc. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

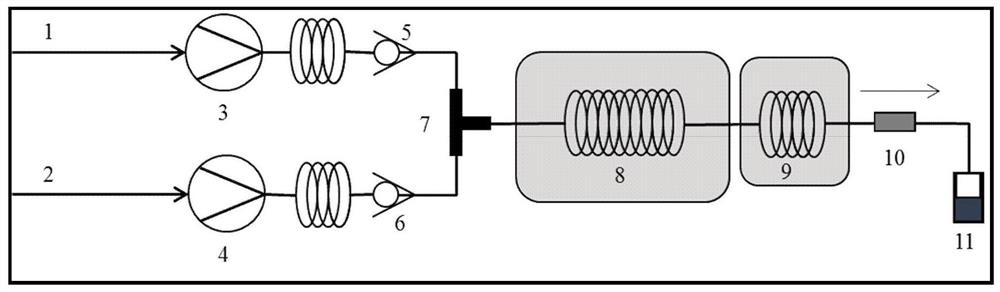

Embodiment 1

[0017] Prepare 1.25M γ-butyrolactone solution 1 and 1.5M methylamine solution 2 with ethylene glycol as a solvent, and the two materials pass through metering pump 3 and metering pump 4 through one-way flow at 0.1ml / min and 0.1ml / min respectively. The valves 5 and 6 are sent to the micro-mixer 7 and then enter the micro-reactor system to start the reaction at normal temperature. After that, the reaction liquid enters the air bath temperature control zone 8. The temperature in the temperature control zone is controlled at 290°C. The reaction residence time in the zone is 13.3min, and the reacted material enters the cooling zone 9, and the cold fluid heat exchange is used to suppress the reaction. The residence time of the reaction suppression section is 42 seconds, and the pressure of the system is stabilized at 5.2 through the back pressure valve 10. MPa, the reaction product is collected at the outlet of the microreactor system, and the collected sample 11 is processed and ana...

Embodiment 2

[0019] Prepare 1.25M gamma-butyrolactone solution 1 and 1.5M ethylamine solution 2 with ethylene glycol as a solvent, and the two materials pass through metering pump 3 and metering pump 4 through one-way The valves 5 and 6 are sent to the micro-mixer 7 and then enter the micro-reactor system to start the reaction at normal temperature. After that, the reaction liquid enters the air bath temperature control zone 8. The temperature in the temperature control zone is controlled at 290°C. The reaction residence time in the zone is 13.3min, and the reacted material enters the cooling zone 9, and the cold fluid heat exchange is used to suppress the reaction. The residence time of the reaction suppression section is 42 seconds, and the pressure of the system is stabilized at 5.2 through the back pressure valve 10. MPa, the reaction product was collected at the outlet of the microreactor system, and the collected sample 11 was processed and then analyzed by gas chromatography and comb...

Embodiment 3

[0021] Use ethylene glycol as a solvent to prepare 2M γ-butyrolactone solution 1 and 2.8M methylamine solution 2, and the two materials pass through metering pump 3 and metering pump 4 through the check valve at flow rates of 0.1ml / min and 0.1ml / min respectively 5 and 6 are transported to the micro-mixer 7 and then enter the micro-reactor system to start the reaction at room temperature, and then the reaction liquid enters the air bath temperature control zone 8, the temperature in the temperature control zone is controlled at 290 ° C, and the two materials are in the temperature control zone The reaction residence time of the reaction is 13.3min, and the reacted material enters the cooling zone 9, and the cold fluid is used to exchange heat to suppress the reaction. The residence time of the reaction suppression section is 42 seconds, and the pressure of the system is controlled at 5.2MPa through the back pressure valve 10. , the reaction product was collected at the outlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com