Strontium titanate-based ceramic material with high energy storage density and low dielectric loss and preparation method thereof

A high energy storage density, ceramic material technology, applied in the field of energy storage ceramics, can solve the problems of low saturation polarization, limited application, low energy storage density, etc., achieve uniform grain size distribution, fast and efficient drying, high storage capacity. The effect of energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] (1-x)SrTiO of the present invention 3 -xBi 0.48 La 0.02 Na 0.48 Li 0.02 Ti 0.98 Zr 0.02 o 3 The preparation method comprises the following steps:

[0050] (1) According to the chemical formula SrTiO 3 , will analyze pure SrCO 3 and TiO 2 Mix the ingredients evenly, then dry at 100°C, pass through a 120-mesh sieve, briquette, and then pre-fire at 1150-1200°C for 3-5 hours to obtain a blocky solid, then crush the blocky solid and pass through a 120-mesh sieve , to get SrTiO 3 Powder;

[0051] (2) According to the chemical formula Bi 0.48 La 0.02 Na 0.48 Li 0.02 Ti 0.98 Zr 0.02 o 3 , will Bi 2 o 3 , La 2 o 3 、Na 2 CO 3 , Li 2 CO 3 、TiO 2 and ZrO 2 Carry out ingredients and mix evenly, then sieve and briquette, and then pre-calcine at 800-850°C for 3-4 hours to obtain a block solid, then crush the block solid and pass through a 120-mesh sieve to obtain Bi 0.48 La 0.02 Na 0.48 Li 0.02 Ti 0.98 Zr 0.02 o 3 Powder;

[0052] (3) the SrTiO of s...

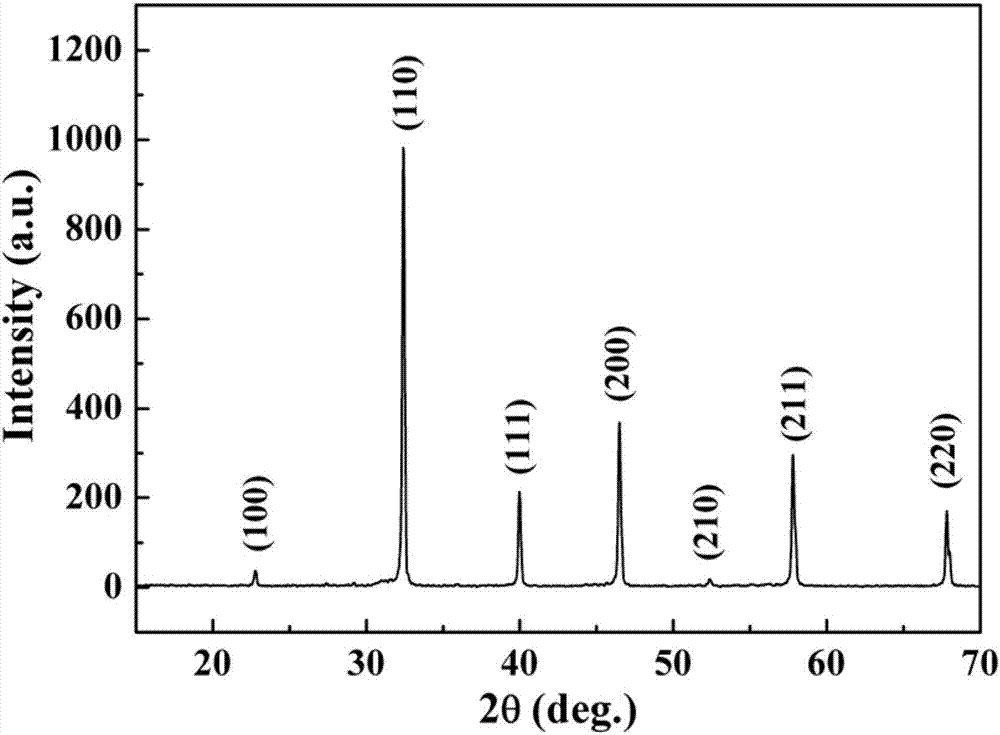

Embodiment 1

[0063] The chemical formula of the ceramic material in this example is: (1-x)SrTiO 3 -xBi 0.48 La 0.02 Na 0.48 Li 0.02 Ti 0.98 Zr 0.02 o 3, where x represents Bi 0.48 La 0.02 Na 0.48 Li 0.02 Ti 0.98 Zr 0.02 o 3 Mole fraction, and x=0.1.

[0064] The preparation method of the above-mentioned strontium titanate-based ceramic material with high energy storage density and low dielectric loss comprises the following steps:

[0065] (1) According to the chemical formula SrTiO 3 will analyze pure SrCO 3 and TiO 2 After batching, use absolute ethanol as the medium, mix evenly through ball milling for 12 hours, then dry at 100°C, pass through a 120-mesh sieve, briquette, and pre-calcine at 1150°C for 5 hours to obtain a block solid, and then the block After the solid is crushed and passed through a 120-mesh sieve, the SrTiO 3 Powder;

[0066] (2) According to the chemical formula Bi 0.48 La 0.02 Na 0.48 Li 0.02 Ti 0.98 Zr 0.02 o 3 Bi 2 o 3 , La 2 o 3 , Na ...

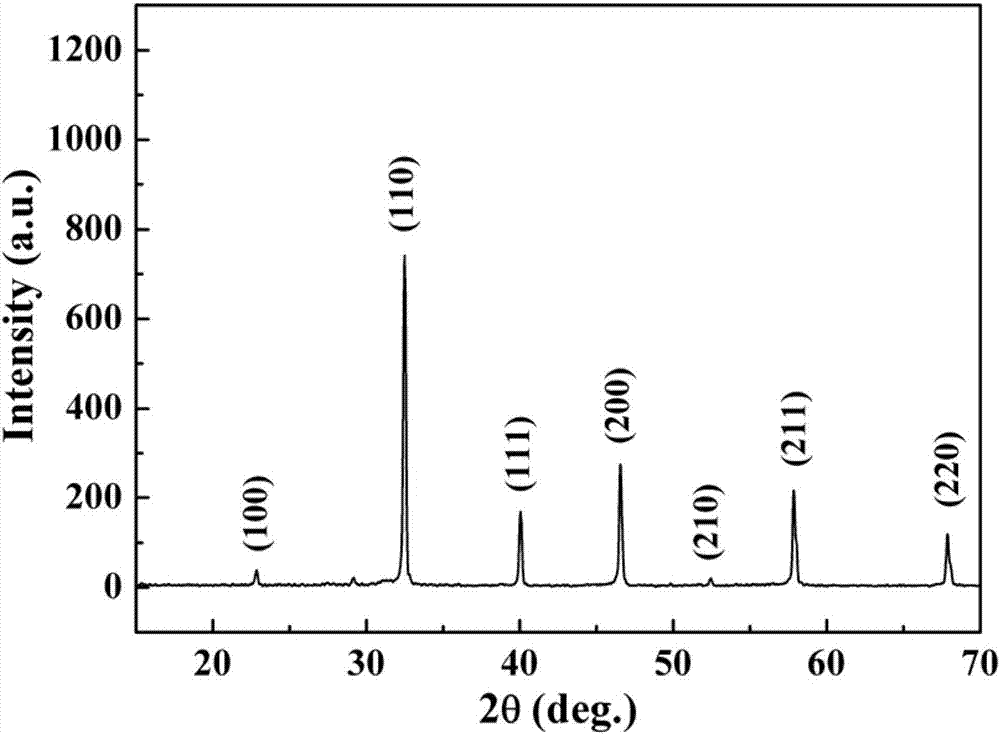

Embodiment 2

[0074] The chemical formula of the ceramic material in this example is: (1-x)SrTiO 3 -xBi 0.48 La 0.02 Na 0.48 Li 0.02 Ti 0.98 Zr 0.02 o 3 , where x represents Bi 0.48 La 0.02 Na 0.48 Li 0.02 Ti 0.98 Zr 0.02 o 3 Mole fraction, and x=0.2.

[0075] The preparation method of the above-mentioned strontium titanate-based ceramic material with high energy storage density and low dielectric loss comprises the following steps:

[0076] (1) According to the chemical formula SrTiO 3 will analyze pure SrCO 3 and TiO 2 After batching, use absolute ethanol as the medium, mix evenly through ball milling for 14 hours, then dry at 100°C, pass through a 120-mesh sieve, briquette, and pre-calcine at 1180°C for 4 hours to obtain a block solid, and then the block After the solid is crushed and passed through a 120-mesh sieve, the SrTiO 3 Powder;

[0077] (2) According to the chemical formula Bi 0.48 La 0.02 Na 0.48 Li 0.02 Ti 0.98 Zr 0.02 o 3 Bi 2 o 3 , La 2 o 3 、Na ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com