Steel pipe inner wall derusting machine

A technology of steel pipe inner wall and derusting machine, which is applied in the field of pipeline processing equipment, can solve the problems of non-cleaning, waste of manpower, high price, etc., and achieve the effect of meeting the needs of derusting and derusting thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be specifically described below with reference to the accompanying drawings.

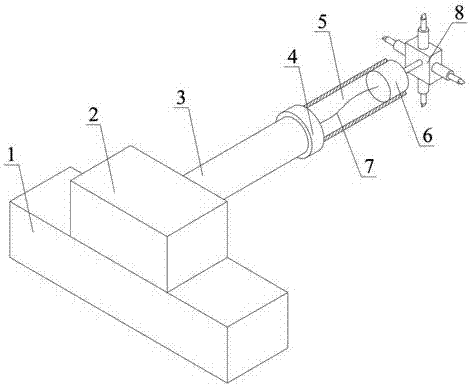

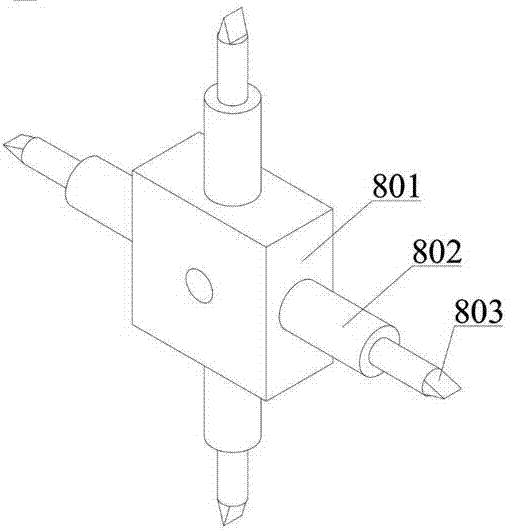

[0022] Such as Figures 1 to 3 As shown, a steel pipe inner wall derusting machine includes a fixed base 2, an extending mechanism fixed horizontally on the fixing base 2, a driving device fixedly arranged on the extending mechanism, and a rust remover 8 driven by the driving device.

[0023] The fixed base 2 is fixedly arranged on a counterweight base 1 . A control device is arranged in the fixed seat 2, and the control device includes a servo drive and a hydraulic cylinder drive, both of which are prior art and will not be repeated here.

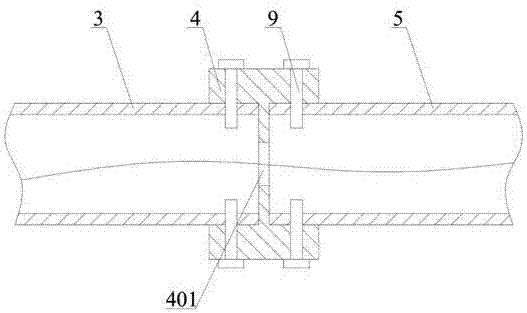

[0024] The extension mechanism is composed of several detachably connected extension tubes 3, and all the extension tubes 3 are connected in sequence. Two adjacent extension pipes 3 are detachably connected through a connector 4, the connector 4 is set as a cylindrical structure, and two slots are opened on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com