Pulse type airflow mixer

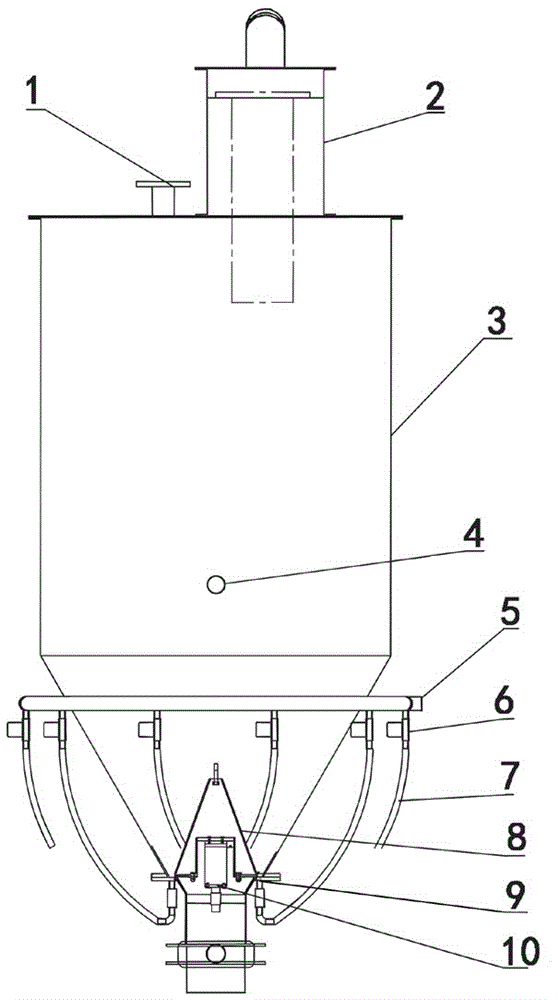

A kind of airflow mixing and pulse technology, which is applied in the direction of mixers, dissolution, chemical instruments and methods, etc., can solve the problems of broken products, mechanical transmission friction heat, affecting product quality, etc., and achieve the effect of fast speed and large mixing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

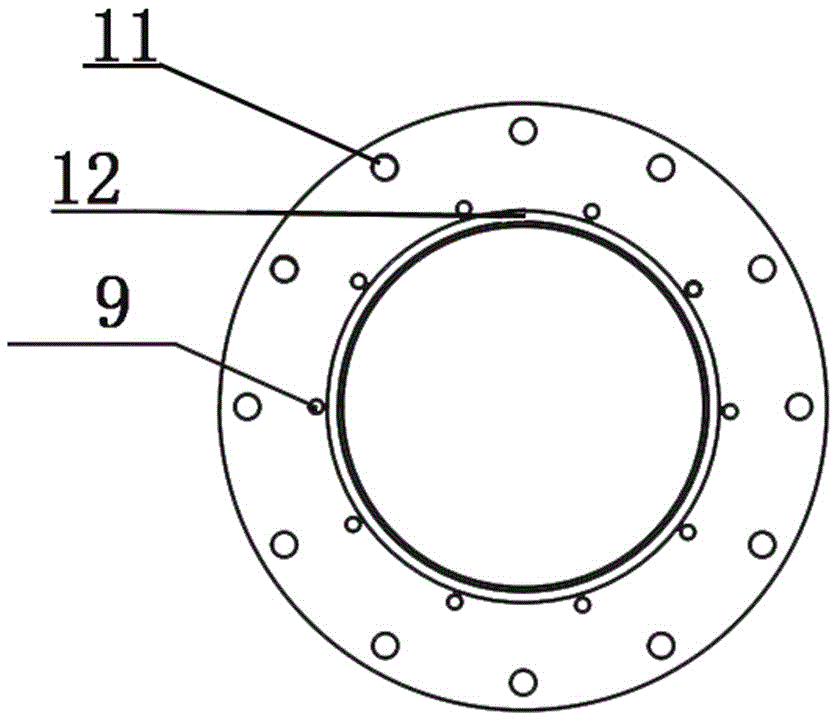

[0030] Powder mixing, according to the powder mixing output, select the appropriate number of nozzles of the mixing head and the pressure and flow of compressed air, controlled by the PLC programmable controller, and perform single-cycle airflow injection homogenization in the form of pulses, combined airflow injection homogenization Homogenize with air jet injection. The material instantly rises spirally along the cylinder wall with the compressed air, and forms a fluidized state. After several pulse blowing and pause gaps, the material in the entire volume is quickly and evenly mixed.

[0031] For powder discharge, open the discharge butterfly valve and discharge the material into the required container.

[0032] The above is only a specific embodiment of the present invention, but the scope of protection of the present invention is not limited thereto. Any person skilled in the art can easily think of changes or substitutions within the technical scope disclosed in the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com