Shock absorber guiding device

A technology of guides and shock absorbers, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of powder metallurgy process without improvement, increase costs, etc., achieve good strength and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

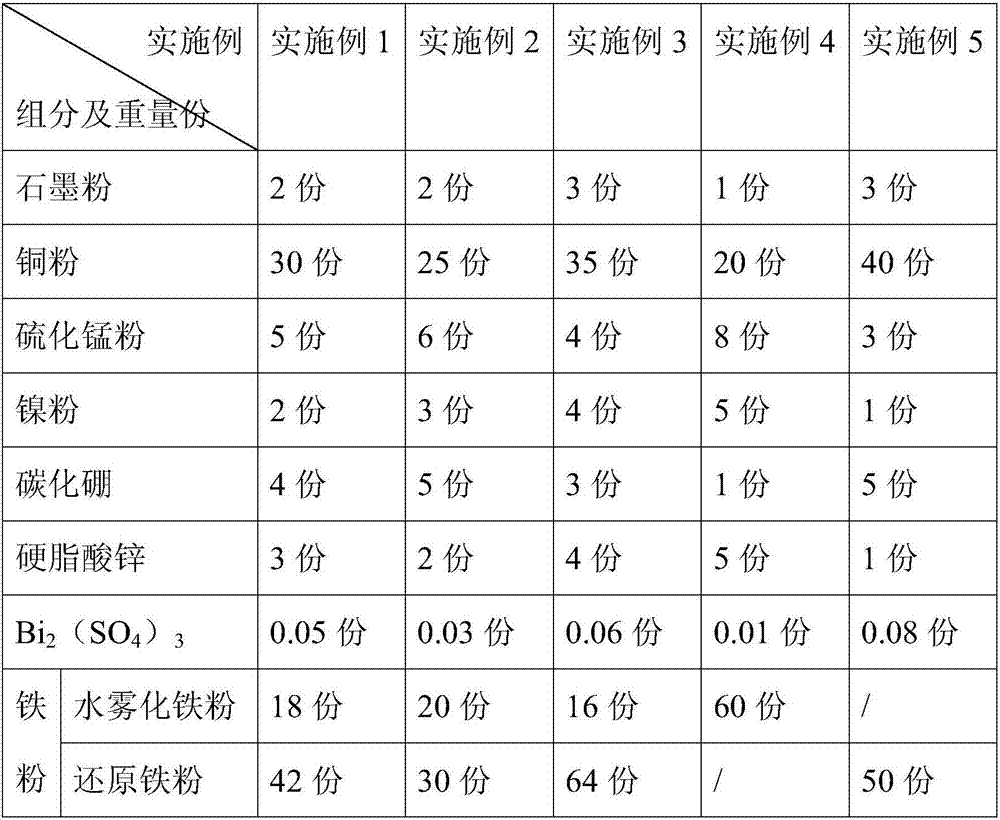

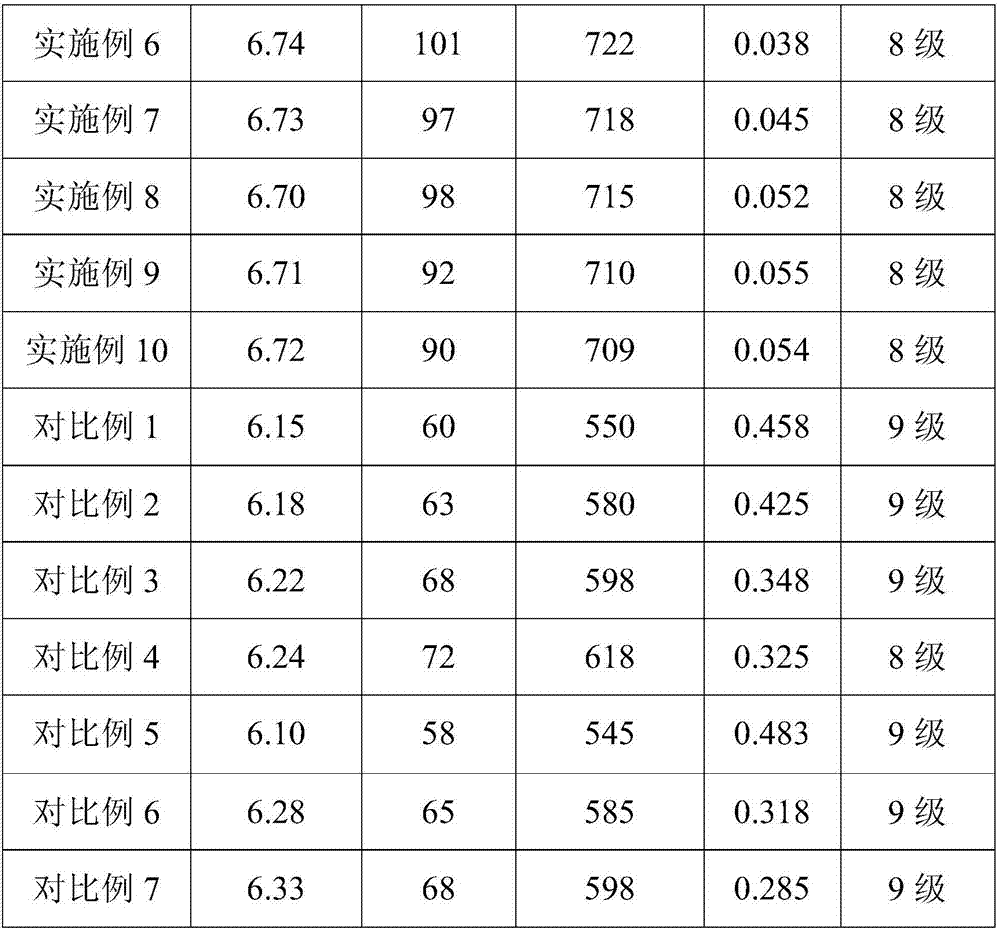

Examples

Embodiment 6

[0031] Compression molding: Weigh the raw materials according to the components and parts by weight of the shock absorber guide described in Example 1 in Table 1 and mix them uniformly, and press the mixed raw materials at 540 MPa to obtain a guide blank;

[0032] Sintering: put the guide blank into a mesh belt sintering furnace, and sinter it at 1180°C under gas protection to obtain the guide blank; during the sintering process, the sintering is carried out under the protection of hydrogen and nitrogen, and the The volume ratio is 3:1, and the net speed is 100mm / s;

[0033] Secondary pressing: After coating a layer of protective agent on the surface of the guide blank, carry out secondary pressing at 540MPa to obtain a semi-finished guider; the protective agent includes the following components in parts by weight: fluorine oil: 40 parts, hydroxypropyl Methyl cellulose: 15 parts, glycerol: 12 parts, magnesium oxide: 3 parts, silicon oxide: 4 parts, tungsten carbide: 3 parts; ...

Embodiment 7

[0036] Compression molding: Weigh the raw materials according to the components of the shock absorber guide described in Example 2 in Table 1 and their parts by weight and mix them evenly, and press the mixed raw materials at 530 MPa to obtain a guide blank;

[0037] Sintering: put the guide blank into a mesh belt sintering furnace, and sinter it at 1150°C under gas protection to obtain the guide blank; during the sintering process, the sintering is carried out under the protection of hydrogen and nitrogen, and the The volume ratio is 3:1, and the net speed is 110mm / s;

[0038] Secondary pressing: After coating a layer of protective agent on the surface of the guide blank, carry out secondary pressing at 550 MPa to obtain a semi-finished guider; the protective agent includes the following components in parts by weight: fluorine oil: 35 parts, hydroxypropyl Methyl cellulose: 18 parts, glycerol: 11 parts, magnesium oxide: 4 parts, silicon oxide: 2 parts, tungsten carbide: 3 part...

Embodiment 8

[0041] Compression molding: Weigh the raw materials according to the components and parts by weight of the shock absorber guide described in Example 3 in Table 1 and mix them uniformly, and press the mixed raw materials at 550 MPa to obtain a guide blank;

[0042] Sintering: put the guide blank into a mesh belt sintering furnace, and sinter it at 1200°C under gas protection to obtain the guide blank; during the sintering process, the sintering is carried out under the protection of hydrogen and nitrogen, and the The volume ratio is 2:1, and the net speed is 105mm / s;

[0043] Secondary pressing: After coating a layer of protective agent on the surface of the guide blank, carry out secondary pressing at 530MPa to obtain a semi-finished guider; the protective agent includes the following components in parts by weight: fluorine oil: 45 parts, hydroxypropyl Methyl cellulose: 12 parts, glycerol: 14 parts, magnesium oxide: 2 parts, silicon oxide: 4 parts, tungsten carbide 2 parts;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com