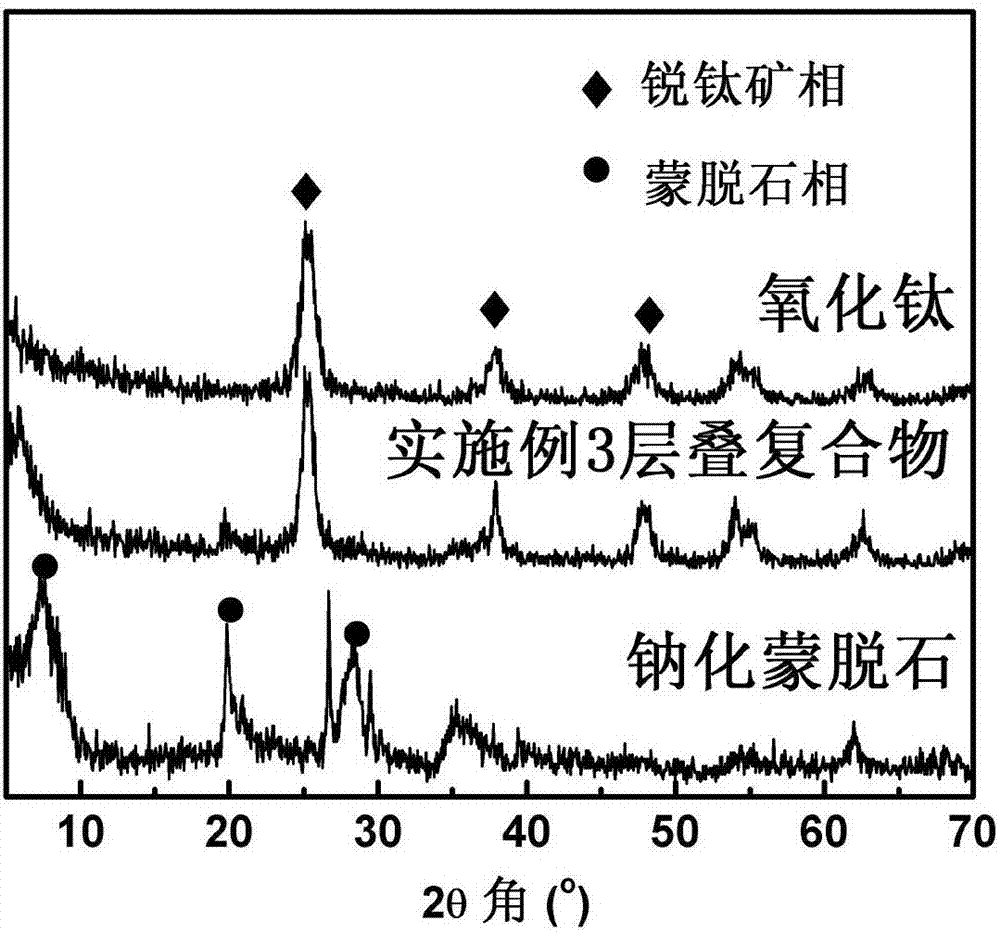

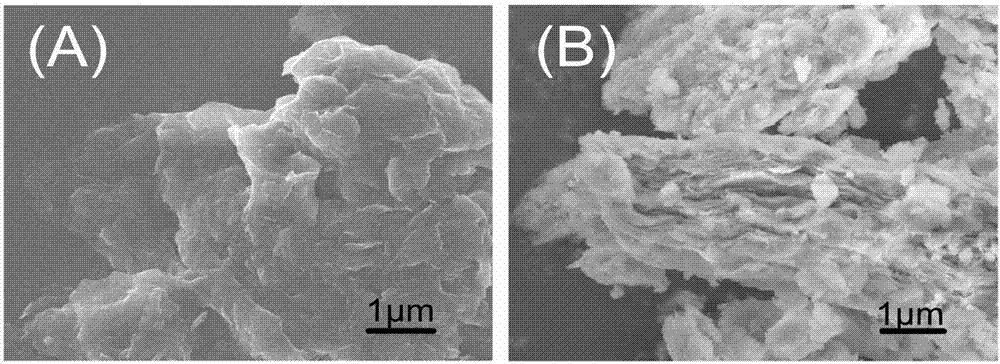

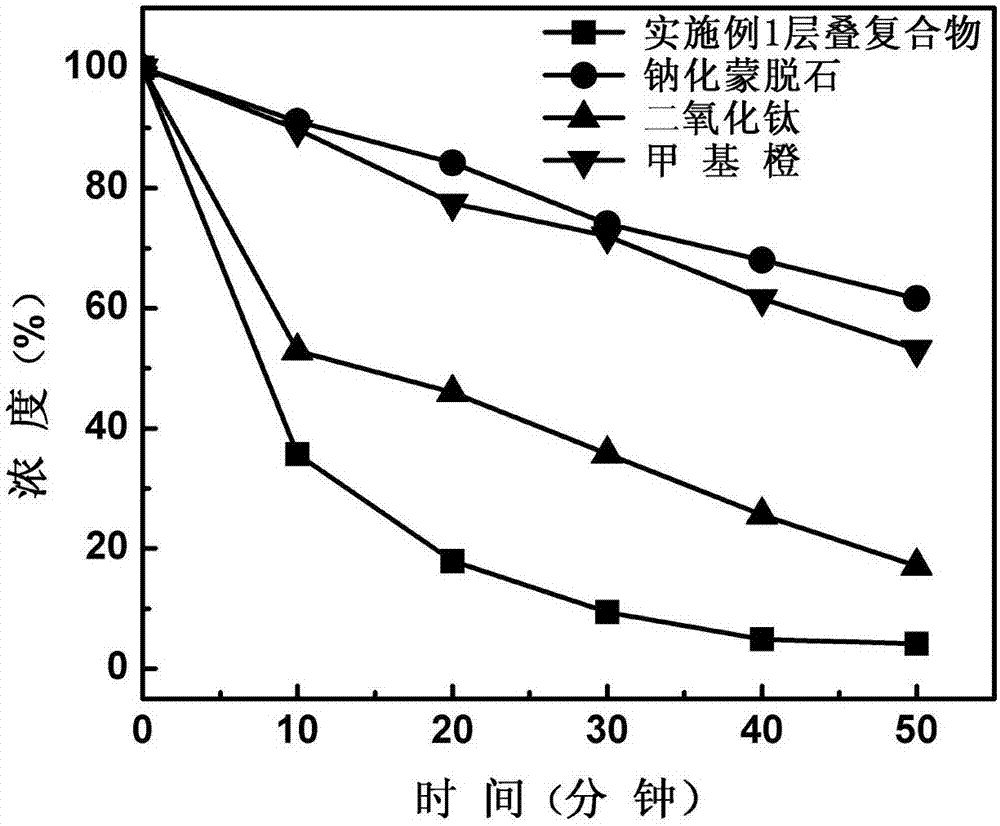

Laminated composite material of anatase and montmorillonite and preparation method thereof

A composite material and montmorillonite micro-layer technology, applied in the field of mineral-based composite materials, can solve problems such as poor crystallinity, reduce difficulty, improve adsorption performance, and avoid the use of organic precursors and organic modifiers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028](1) Get 3g sodium montmorillonite and add 600mL deionized water to make 0.5wt% sodium montmorillonite suspension, then adjust the pH value of montmorillonite suspension to 9 with ammonia water, and carry out 2h Stir magnetically to obtain a montmorillonite suspension in which the microplatelets are fully opened.

[0029] (2) Take 3 g of titanium sulfate and add 42 mL of deionized water to make a solution, and then add ammonia water dropwise to adjust its pH value to 6. At this time, the titanium salt is hydrolyzed to form a white precursor slurry. Then magnetically stir for 30 min.

[0030] (3) under stirring, the white slurry generated in step 2 is added dropwise to the montmorillonite suspension obtained in step 1, and the pH of the above-mentioned mixed liquid is readjusted to 3 with 25% dilute sulfuric acid solution, and then Magnetic stirring was performed for 1 h.

[0031] (4) Put the mixed solution in step 3 into a polytetrafluoroethylene-lined stainless steel r...

Embodiment 2

[0034] (1) Get 3g sodium montmorillonite and add 150mL deionized water to make 2wt% sodium montmorillonite suspension, then adjust the pH value of montmorillonite suspension to 8 with ammonia water, and carry out 2h magnetic Stir to obtain a montmorillonite suspension in which the microplatelets are fully opened.

[0035] (2) Take 9 g of titanium sulfate and add 378 mL of deionized water to form a solution, then add NaOH solution dropwise to adjust its pH value to 7, and then the titanium salt is hydrolyzed to form a white precursor slurry. Then magnetically stir for 30 min.

[0036] (3) under stirring, the white slurry generated in step 2 is added dropwise to the smectite suspension obtained in step 1, and the pH of the above mixed liquid is readjusted to 5 with 25% dilute sulfuric acid solution, after that Magnetic stirring was performed for 1 h.

[0037] (4) Put the mixed solution in step 3 into a polytetrafluoroethylene-lined stainless steel reaction kettle, and keep it ...

Embodiment 3

[0040] (1) Get 3g sodium montmorillonite and add 1500mL deionized water to make 0.2wt% sodium montmorillonite suspension, then adjust the pH value of montmorillonite suspension to 11 with ammonia water, and carry out 2h Stir magnetically to obtain a montmorillonite suspension in which the microplatelets are fully opened.

[0041] (2) Take 3 g of titanium sulfate and add 42 mL of deionized water to form a solution, then add NaOH solution dropwise to adjust its pH value to 10, and then the titanium salt is hydrolyzed to form a white precursor slurry. Then magnetically stir for 30 min.

[0042] (3) under stirring, the white slurry generated in step 2 is added dropwise to the smectite suspension obtained in step 1, and the pH of the above-mentioned mixed liquid is readjusted to 4 with 25% dilute sulfuric acid solution, and then Magnetic stirring was performed for 1 h.

[0043] (4) Put the mixed liquid in step 3 into a polytetrafluoroethylene-lined stainless steel reaction kettle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com