Preparation method of medical fiber wound dressing prepared through composition of natural polysaccharide derivatives and natural polymers

A technology of natural polymers and natural polysaccharides, which is applied in the field of preparation of natural polysaccharide derivatives/natural polymer composite fiber medical wound dressings, can solve problems such as not being able to meet the needs of skin tissue repair, and achieve excellent biodegradability and strength. control, excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Under the protection of nitrogen at 85°C, dissolve 3.0g dextran (molecular weight: 40,000) in 8wt% LiCl / DMF solution. After complete dissolution, the solution temperature drops to 55°C, add 5.6g pyridine, and stir for 40min. Add 8.6 g of methacrylic anhydride dropwise, react for 5 hours, cool down to room temperature after the reaction, precipitate in cold isopropanol, centrifuge, and vacuum dry to obtain modified dextran derivatives.

[0028] 2) Take 0.5g of the modified dextran derivative obtained in step 1), 0.5g of gelatin, 2g of deionized water, 1.1×10 -3 gDarocur 2959, fully carry out magnetic stirring at 40°C, and put the solution under ultrasonication for 1-2 hours to precipitate all the bubbles to obtain a uniform and transparent electrospinning solution.

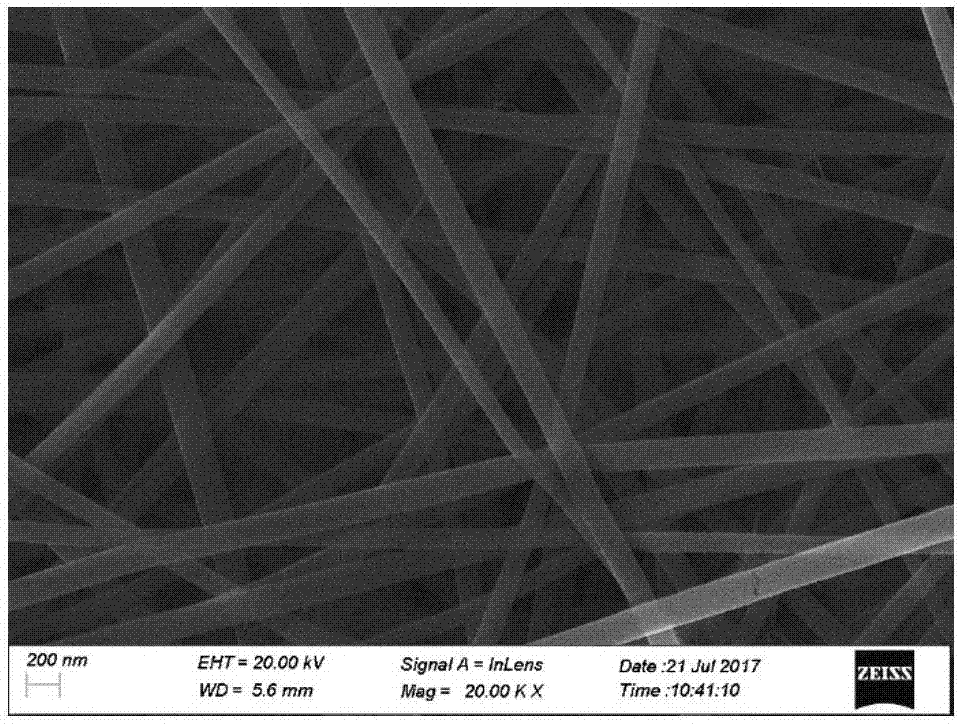

[0029] 3) Take the electrospinning solution prepared in step 2), and use a multi-nozzle electrospinning machine to perform large-area electrospinning to obtain composite fibers of dextran derivatives and ...

Embodiment 2

[0032]1) Under nitrogen protection at 60°C, dissolve 3.0g konjac glucomannan (molecular weight: 200,000) in 6wt% LiCl / DMF. After complete dissolution, the solution temperature drops to 40°C, add 8.5g pyridine, and stir for 20min , add 13.0 methacrylic anhydride dropwise, react for 24 hours, cool down to room temperature after the reaction, precipitate in cold isopropanol, centrifuge, and vacuum dry to obtain modified konjac glucomannan derivatives.

[0033] 2) Take 0.2g of the modified konjac glucomannan derivative obtained in step 1), 0.8g of hyaluronic acid, 3.0g of deionized water, 5.5×10 -4 g Darocur 2959, fully carry out magnetic stirring at 40°C, and place the solution for 1-2 hours in ultrasonic to make all the bubbles precipitate out to obtain a uniform and transparent electrospinning solution.

[0034] 3) Take the electrospinning solution prepared in step 2), and use a multi-nozzle electrospinning machine to perform large-area electrospinning to obtain composite fiber...

Embodiment 3

[0037] 1) Under nitrogen protection at 70°C, dissolve 3.0g inulin (molecular weight 6,200) in 5wt% LiCl / DMF. After complete dissolution, the solution temperature drops to 40°C, add 5.6g pyridine, stir for 30min, dropwise Add 8.6g of methacrylic anhydride, react for 12h, cool down to room temperature after the reaction, precipitate in cold isopropanol, centrifuge, and vacuum dry to obtain modified inulin derivatives.

[0038] 2) Take 0.4g of the modified inulin derivative obtained in step 1), 0.6g of carboxymethyl cellulose, 3g of deionized water, 1.1×10 -3 g Quantacure QTX, fully carry out magnetic stirring at 40°C, and place the solution for 1-2 hours in ultrasonic to make all the bubbles precipitate out to obtain a uniform and transparent electrospinning solution.

[0039] 3) Take the electrospinning solution prepared in step 2), and use a multi-nozzle electrospinning machine to perform large-area electrospinning to obtain composite fibers of inulin derivatives and carboxyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com