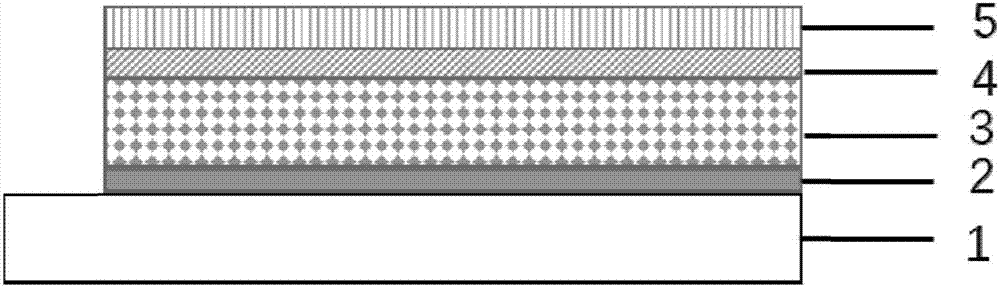

Organic-inorganic hybrid perovskite solar cell and preparation method thereof

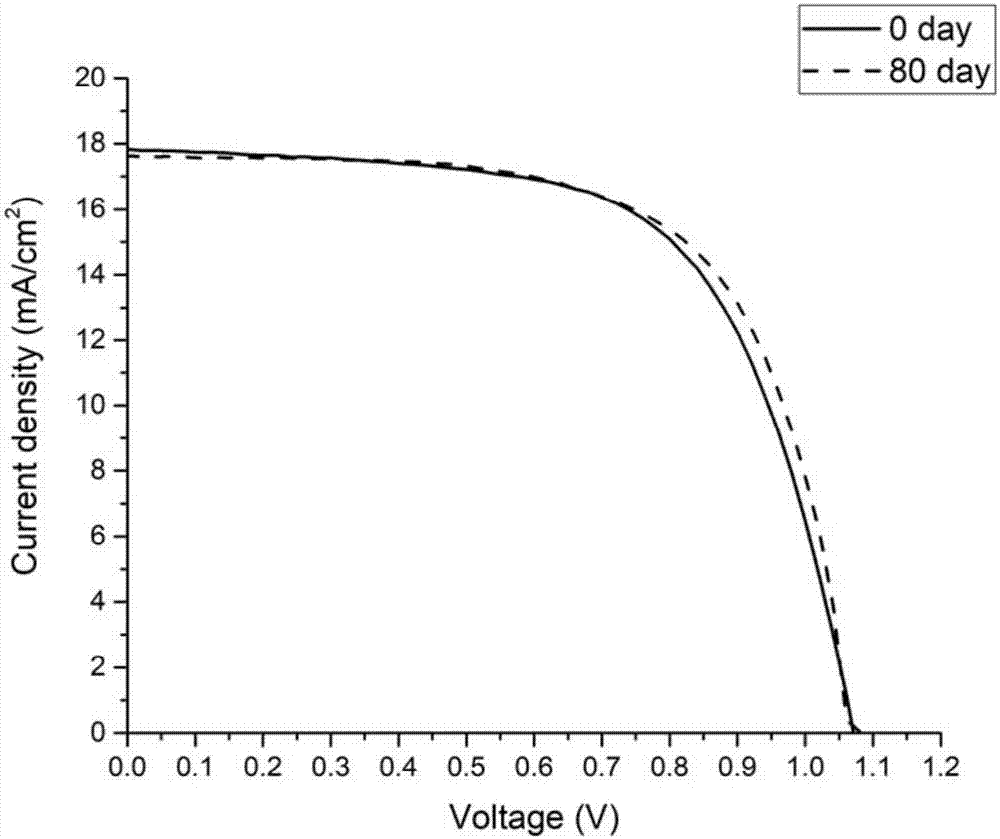

A solar cell and perovskite technology, applied in the field of solar energy utilization, can solve the problems of no more than 300nm and poor stability, and achieve the effects of excellent stability, reduced preparation conditions, and reduced photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Deposit TiO on the transparent conductive electrode 2 Dense layer: Add 1g tetraisopropyl titanate to 1g acetylacetone and 3g ethanol solution to prepare TiO 2 Precursor, 50 nm thick TiO deposited by spray pyrolysis at 450 °C 2 dense layer.

[0029] (2) Preparation of mixed cation organic-inorganic hybrid perovskite solution: the molar ratio FAI:PbI 2 :MABr:PbBr 2 =0.70:070:0.30:0.30 The mixture is added to the mixed solution of DMSO and DMF, the mass ratio of DMF and DMSO is 9:1, and the concentration of the obtained mixed cation organic-inorganic hybrid perovskite solution is 0.3mol / L.

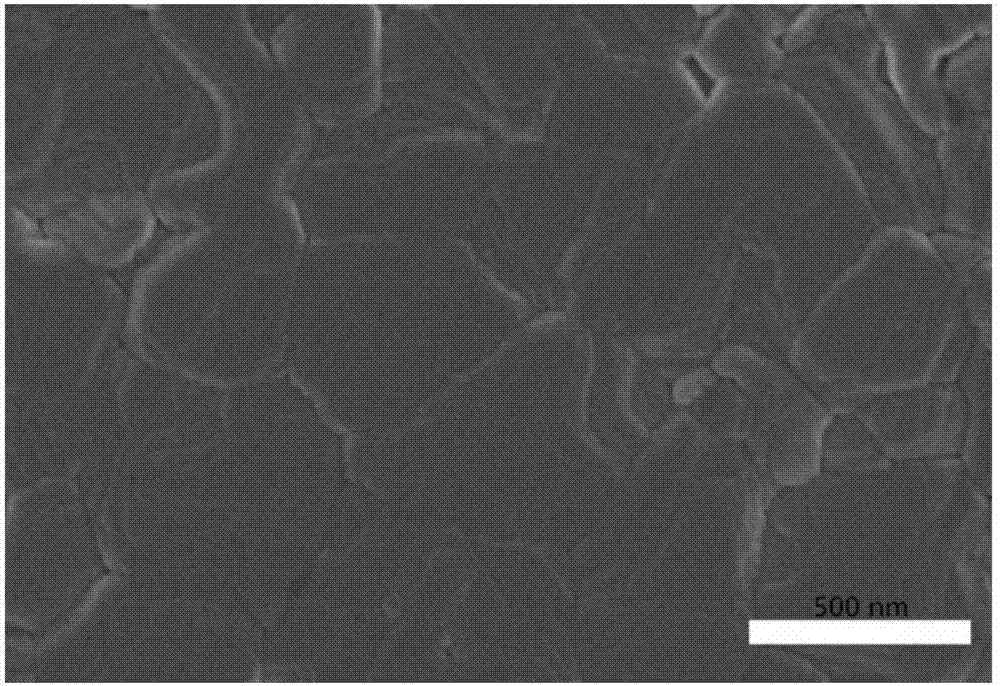

[0030] (3) on TiO 2 Deposition of perovskite films on dense layers: Perovskite films were prepared by thermal substrate spraying in atmospheric environment, where the carrier gas was N 2 , the spray gun pressure is 3 atmospheres, the hot substrate temperature is 130°C, the spraying time is controlled, the film thickness is 200nm, and then annealed at 100°C for 15min.

[0031]...

Embodiment 2

[0035] (1) Deposit TiO on the transparent conductive electrode 2Dense layer: Add 1g tetraisopropyl titanate to 1g acetylacetone and 3g ethanol solution to prepare TiO 2 Precursor, 50 nm thick TiO deposited by spray pyrolysis at 450 °C 2 dense layer.

[0036] (2) Preparation of mixed cation organic-inorganic hybrid perovskite solution: the molar ratio FAI:PbI 2 :MABr:PbBr 2 =0.85:0.85:0.15:0.15 The mixture is added to the mixed solution of DMSO and DMF, the mass ratio of DMF and DMSO is 9:1, and the concentration of the obtained mixed cation organic-inorganic hybrid perovskite solution is 0.3mol / L.

[0037] (3) on TiO 2 Deposition of perovskite films on dense layers: Perovskite films were prepared by thermal substrate spraying in atmospheric environment, where the carrier gas was N 2 , the spray gun pressure is 3 atmospheres, the hot substrate temperature is 130°C, the spraying time is controlled, the film thickness is 200nm, and then annealed at 100°C for 15min.

[0038]...

Embodiment 3

[0042] (1) Deposit TiO on the transparent conductive electrode 2 Dense layer: Add 1g tetraisopropyl titanate to 1g acetylacetone and 3g ethanol solution to prepare TiO 2 Precursor, 50 nm thick TiO deposited by spray pyrolysis at 450 °C 2 dense layer.

[0043] (2) Preparation of mixed cation organic-inorganic hybrid perovskite solution: the molar ratio FAI:PbI 2 :MABr:PbBr 2 =0.90:0.90:0.10:0.10 The mixture is added to the mixed solution of DMSO and DMF, the mass ratio of DMF and DMSO is 9:1, and the concentration of the obtained mixed cation organic-inorganic hybrid perovskite solution is 0.3mol / L.

[0044] (3) on TiO 2 Deposition of perovskite films on dense layers: Perovskite films were prepared by thermal substrate spraying in atmospheric environment, where the carrier gas was N 2 , the spray gun pressure is 3 atmospheres, the hot substrate temperature is 130°C, the spraying time is controlled, the film thickness is 200nm, and then annealed at 100°C for 15min.

[0045...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com