Silver gyrus/graphene/gold film three-dimensional SERS (surface-enhanced Raman scattering) substrate and method for preparing same

A graphene and substrate technology, which is applied in the field of preparation of 3D SERS substrates based on gallium gyrus/graphene/gold film composite type, which can solve the effects of enhanced strength, sensitivity and uniformity on the shape, size and periodicity of metal nanostructures, etc. problem, to achieve the effect of easy promotion, increased specific surface area, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

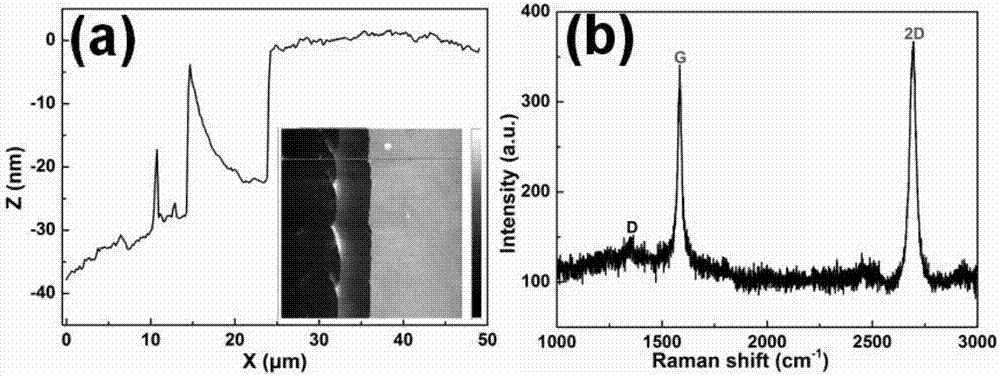

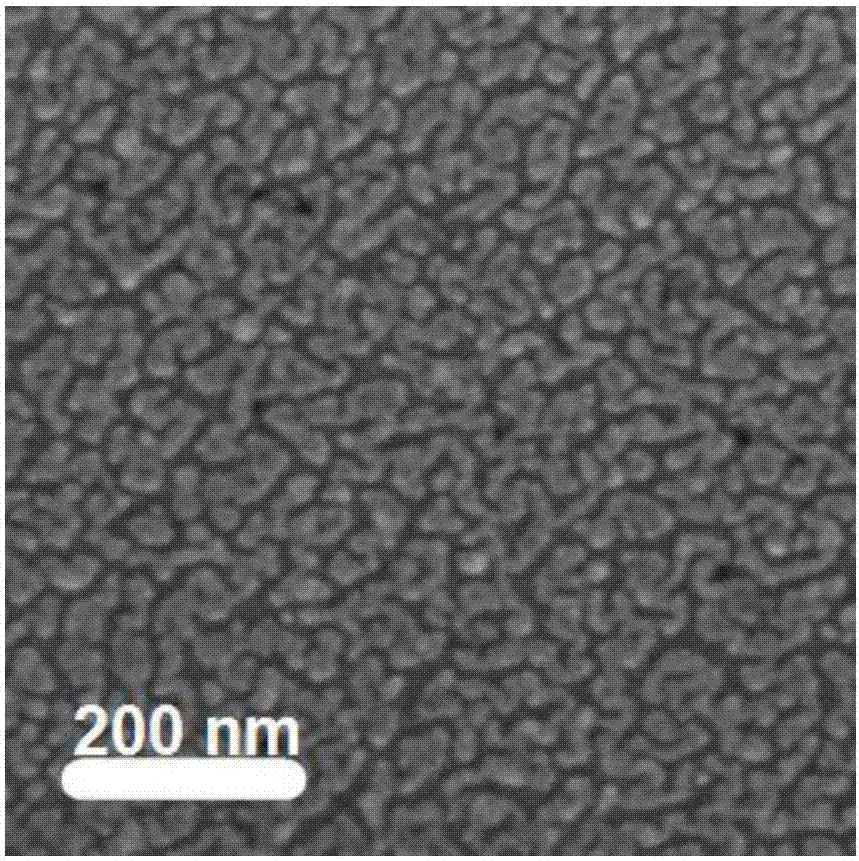

[0043] A preparation method and application of a silver gyrus / graphene / gold film composite three-dimensional Raman enhanced substrate, including the following steps: depositing a gold nano film on the surface of a quartz substrate by a thermal evaporation method, and a wet transfer chemical vapor deposition method ( CVD) grown graphene, and then using a thermal evaporation method to evaporate the silver gyrus nanostructure on the surface of the graphene to obtain a silver gyrus / graphene / gold film composite three-dimensional Raman enhanced substrate. Repeating the above steps can prepare a three-dimensional composite structure of silver gyrus / graphene / gold film on a flexible ultra-thin mica sheet to obtain a flexible Raman enhanced substrate for food safety inspection.

[0044] Further, the thickness of the gold nano film is 10-50 nm.

[0045] Further, the number of graphene layers is 2-10 layers.

[0046] Further, the width of the silver gyrus nanostructure is 10-30 nm, the gap is 1...

Embodiment 1

[0048] A preparation method of a silver gyrus / graphene / gold film composite three-dimensional Raman enhanced substrate includes the following preparation steps:

[0049] 1) Put the quartz substrates into acetone, alcohol and deionized water in turn and ultrasonically clean them in an ultrasonic machine for 15 minutes to obtain a clean quartz substrate;

[0050] 2) Physical vapor deposition (PVD) thermal vapor deposition gold film: put the clean quartz wafer into the thermal vapor deposition equipment, 15cm away from the molybdenum boat (length: 10cm, width: 10mm, thickness: 0.3mm), and place it in the molybdenum boat Add 0.0080g high-purity gold wire, seal, and pump to 5×10 -3 Pa, adjust the current to 130A to obtain a uniform gold film;

[0051] 3) Wet transfer graphene: first coat the protective layer PMMA (polymethyl methacrylate) solution on the copper foil with graphene, let it dry naturally, and put it on the configured FeCl 3 In the solution (1M), make the copper foil float on ...

Embodiment 2

[0057] A method for preparing a flexible silver gyrus / graphene / gold film composite three-dimensional Raman reinforced substrate includes the following preparation steps:

[0058] 1) Put the flexible mica film into acetone, alcohol and deionized water in order for ultrasonic cleaning in an ultrasonic machine for 15 minutes to obtain a clean mica substrate;

[0059] 2) Physical vapor deposition (PVD) thermal vapor deposition gold film: Put the clean mica sheet into the thermal vapor deposition equipment, 15cm away from the molybdenum boat (length: 10cm, width: 10mm, thickness: 0.3mm), and place it in the molybdenum boat Add 0.0080g high-purity gold wire, seal, and pump to 5×10 -3 Pa, adjust the current to 130A to obtain a uniform gold film;

[0060] 3) Wet transfer graphene: First, coat the protective layer PMMA solution on the copper foil with graphene, dry it naturally, and put it on the configured FeCl 3 In the solution (1M), make the copper foil float on the surface of the solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com