A kind of samarium cobalt magnetic material cleaning liquid and cleaning method

A magnetic material and cleaning fluid technology, applied in the field of metal surface cleaning, can solve the problems of unsatisfactory cleaning effect, general cleaning effect and high cleaning cost, and achieve the effects of reducing formula cost, fast and efficient cleaning, and high solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

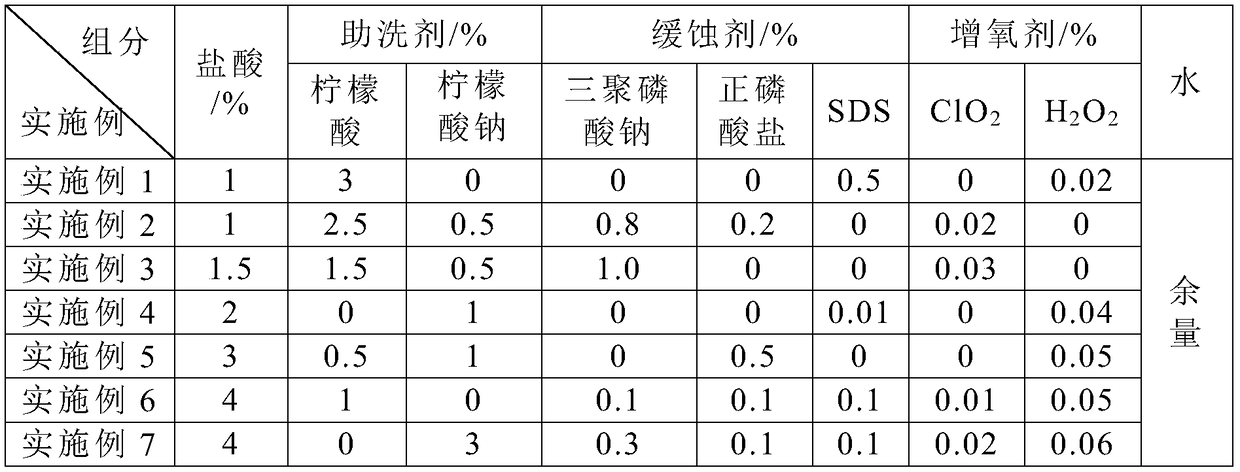

[0042] The samarium-cobalt magnetic material cleaning solution in the embodiment 1-7 of the present invention is prepared from the following components in weight percentage:

[0043] Hydrochloric acid 1%-4%;

[0044] Builder 1%-3%, is one or both of citric acid and sodium citrate, and when the builder is citric acid, the total weight percentage of hydrochloric acid and citric acid is 2%-5%;

[0045] Corrosion inhibitor 0.01%-1%, one or more of tripolyphosphate, orthophosphate and sodium dodecylsulfonate (SDS);

[0046] Oxygenating agent 0.02%-0.08%, is chlorine dioxide (ClO 2 ), hydrogen peroxide (H 2 o 2 ) either or both;

[0047] The balance is water.

[0048] The components and contents of the cleaning solution in Examples 1-7 are as shown in Table 1.

[0049] Table 1: Components and content of cleaning solution in Examples 1-7

[0050]

Embodiment 8-14

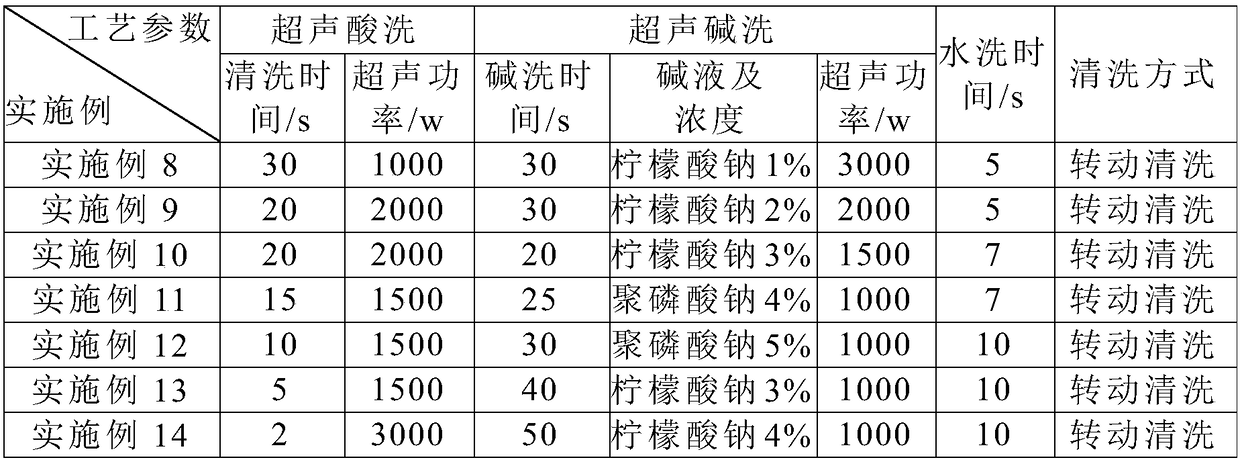

[0052] Use the cleaning solution in Example 7 to clean the samarium cobalt magnetic material to be cleaned, and the cleaning steps are as follows:

[0053] (1), ultrasonic pickling, put the product to be cleaned into an ultrasonic cleaning device whose inner wall is a titanium alloy material, and add a cleaning solution, and rotate and clean it for 2s-30s under an ultrasonic power of 1000W-3000W to obtain a pickling product;

[0054] (2), ultrasonic alkaline cleaning, put the pickling product into an ultrasonic cleaning device whose inner wall is made of stainless steel, and add weak lye, and rotate and clean it for 20s-50s under 1000W-3000W ultrasonic power to obtain the alkaline cleaning product, Weak lye is sodium citrate solution or sodium polyphosphate solution;

[0055] (3), water washing, put the alkali-washed product into standing clear water, rotate and wash for 5s-10s, and obtain the water-washed product;

[0056] (4) Drying with heat, putting the washed product int...

Embodiment 15-20

[0062] The samarium-cobalt magnetic material to be cleaned was cleaned by using the cleaning solutions of Examples 1-6 respectively under the parameter conditions of Example 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com