Multi-stage deep removing process of biomass gas tar

A technology of biomass gas and tar, applied in gas dust removal, petroleum industry, combustible gas purification, etc. Excellent shower cooling effect, reducing operating load and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

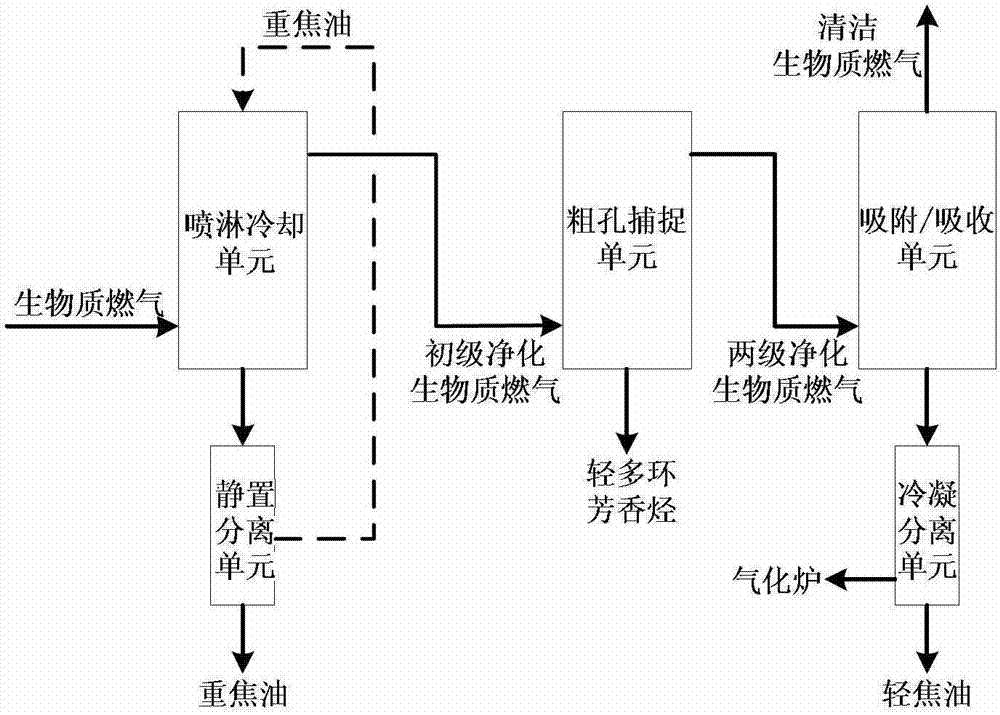

[0028] Its process principle block diagram is as follows figure 1 As shown, the tar-rich 800°C biomass gas produced by the biomass gasifier first enters the spray cooling unit after dust removal, and the tar content is 1000mg / Nm 3 , is sprayed and cooled to 120°C by the heavy tar liquid, and heat is released; the heavy tar liquid enters the static separation unit to obtain heavy tar and residue products, and part of the heavy tar returns to the spray cooling unit as a spray cooling medium.

[0029] The primary purified biomass gas enters the coarse-pore capture unit, and utilizes the capillary coagulation and interception of the coarse pores of the 2800-mesh wire mesh to remove most of the light polycyclic aromatic hydrocarbons (2-3 rings) tar, and the temperature drops to 80°C . The tar-retained screen is blown out of the tar by steam, and the tar is used as a product, or returned to the gasifier as a raw material; the purified screen is reused for the coarse-hole capture un...

Embodiment 2

[0032] Its process principle block diagram is as follows figure 1 As shown, the tar-rich 1000°C biomass gas produced by the biomass gasifier first enters the spray cooling unit after dust removal, and the tar content is 2000mg / Nm 3 , is sprayed and cooled by the heavy tar liquid to 110°C, and heat is released; the heavy tar liquid enters the static separation unit to obtain heavy tar and residue products, and part of the heavy tar returns to the spray cooling unit as a spray cooling medium.

[0033] The primary purified biomass gas enters the coarse pore capture unit, and utilizes the capillary condensation and interception of charcoal coarse pores to remove most of the light polycyclic aromatic hydrocarbons (2-3 rings) tar, and the temperature drops to 90°C. The charcoal with trapped tar is returned to the gasifier as feedstock.

[0034] The biomass gas after the two-stage purification enters the absorption unit, and uses the absorption of light diesel oil to remove a small ...

Embodiment 3

[0036] Such as the multi-stage deep removal process of biomass gas tar in Example 1, the temperature of biomass gas is 750°C, and the tar content is 2500mg / Nm 3 . The cooling temperature of the spray cooling unit is 105°C. The coarse capture unit is filled with wood chips and operates at 80°C; the charcoal with trapped tar is returned to the gasifier as feedstock. The adsorbent of the adsorption unit is activated carbon fiber, and the adsorption temperature is 40°C; water vapor is used for desorption. After purification, the tar dew point of biomass gas is reduced to -10°C, and subsequent use will not condense and corrode equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com