Acid and alkali resistant metal powder coating and preparation method thereof

A metal powder, acid and alkali resistant technology, applied in powder coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of large differences in quality and poor consistency of metal powder coatings, and achieve protection from acid and alkali corrosion, reduce Interfering factors, effect of particle uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

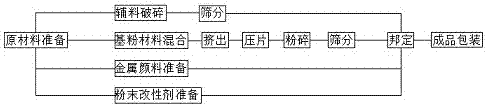

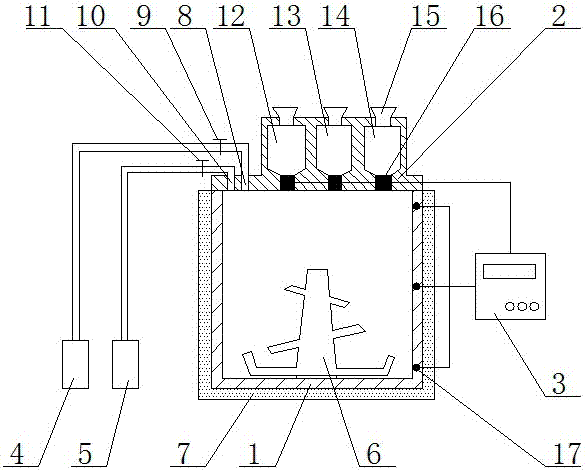

Method used

Image

Examples

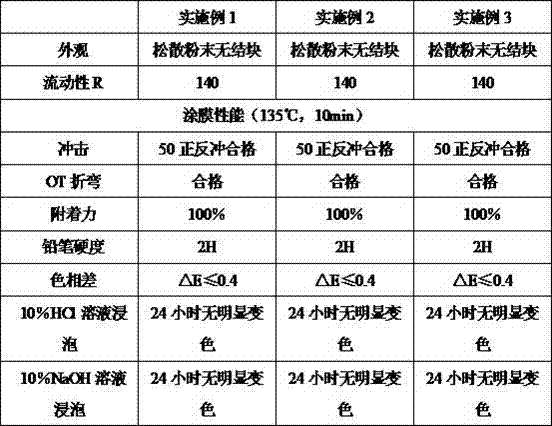

Embodiment 1

[0048] Produce a kind of acid and alkali resistant metal powder coating, its specific steps are as follows:

[0049] a. Weigh the raw materials and prepare the following raw materials in parts by mass:

[0050] Bisphenol A epoxy resin 35kg;

[0051] Hydroxy acrylic resin 25kg;

[0052] Phenolic resin 15kg;

[0053] 2-methylimidazole 2kg;

[0054] Aluminum silver powder 9kg;

[0055] Sand texture agent 2kg;

[0056] Titanium dioxide 16kg;

[0057] Calcium carbonate 12kg;

[0058] Benzoin 0.5kg;

[0059] White carbon black 0.4kg;

[0060] b. Add the bisphenol A epoxy resin, hydroxyacrylic resin, 2-methylimidazole, sanding agent, titanium dioxide, calcium carbonate and benzoin prepared in step a into the Misekra tank of the mixer for pre-mixing , the mixing time is: 2 minutes at low speed, 6 minutes at high speed; 100r / min at low speed and 300r / min at high speed;

[0061] c, the phenolic resin prepared in step a is added in the resin breaker and carried out micro-grindi...

Embodiment 2

[0072] Produce a kind of acid and alkali resistant metal powder coating, its specific steps are as follows:

[0073] a. Weigh the raw materials and prepare the following raw materials in parts by mass:

[0074] Bisphenol A type epoxy resin 40kg;

[0075] Hydroxy acrylic resin 30kg;

[0076] Phenolic resin 18kg;

[0077] 2-methylimidazole 3.6kg;

[0078] Aluminum silver powder 10.6kg;

[0079] Sand texture agent 2kg;

[0080] Titanium dioxide 16.8kg;

[0081] Calcium carbonate 13.2kg;

[0082] Benzoin 0.5kg;

[0083] White carbon black 0.4kg;

[0084] b. Add the bisphenol A epoxy resin, hydroxyacrylic resin, 2-methylimidazole, sanding agent, titanium dioxide, calcium carbonate and benzoin prepared in step a into the Misekra tank of the mixer for pre-mixing , the mixing time is: 2 minutes at low speed, 6 minutes at high speed; 100r / min at low speed and 300r / min at high speed;

[0085] c, the phenolic resin prepared in step a is added in the resin breaker and carried ou...

Embodiment 3

[0096] Produce a kind of acid and alkali resistant metal powder coating, its specific steps are as follows:

[0097] a. Weigh the raw materials and prepare the following raw materials in parts by mass:

[0098] Bisphenol A epoxy resin 45kg;

[0099] Hydroxy acrylic resin 35kg;

[0100] Phenolic resin 20kg;

[0101] 2-Methylimidazole 4kg;

[0102] Aluminum silver powder 12kg;

[0103] Sand texture agent 2kg;

[0104] Titanium dioxide 18kg;

[0105] Calcium carbonate 14kg;

[0106] Benzoin 0.5kg;

[0107] White carbon black 0.4kg;

[0108] b. Add the bisphenol A epoxy resin, hydroxyacrylic resin, 2-methylimidazole, sanding agent, titanium dioxide, calcium carbonate and benzoin prepared in step a into the Misekra tank of the mixer for pre-mixing , the mixing time is: 2 minutes at low speed, 6 minutes at high speed; 100r / min at low speed and 300r / min at high speed;

[0109] c, the phenolic resin prepared in step a is added in the resin breaker and carried out micro-grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com