Spent fuel waste resin transport tank truck and transport method

A waste resin and spent fuel technology, which is applied in the direction of goods transport vehicles, freight vehicles, oil tank trucks, etc., can solve the problems of easy blockage of pipelines, difficult maintenance of pipelines, personal injury of maintenance personnel, etc., and achieves convenient operation , simple structure and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

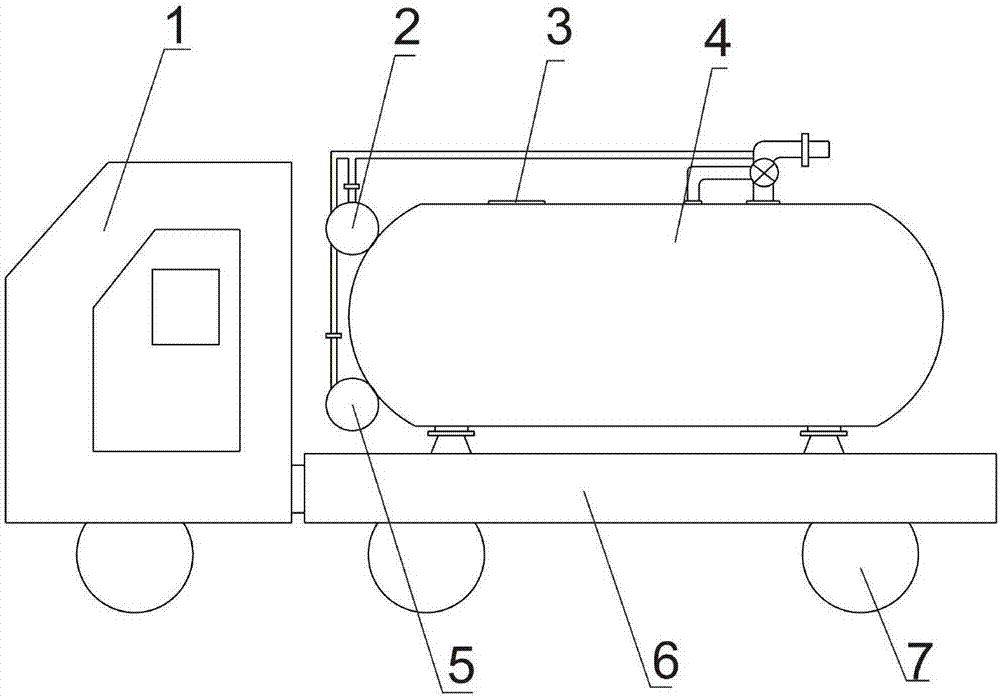

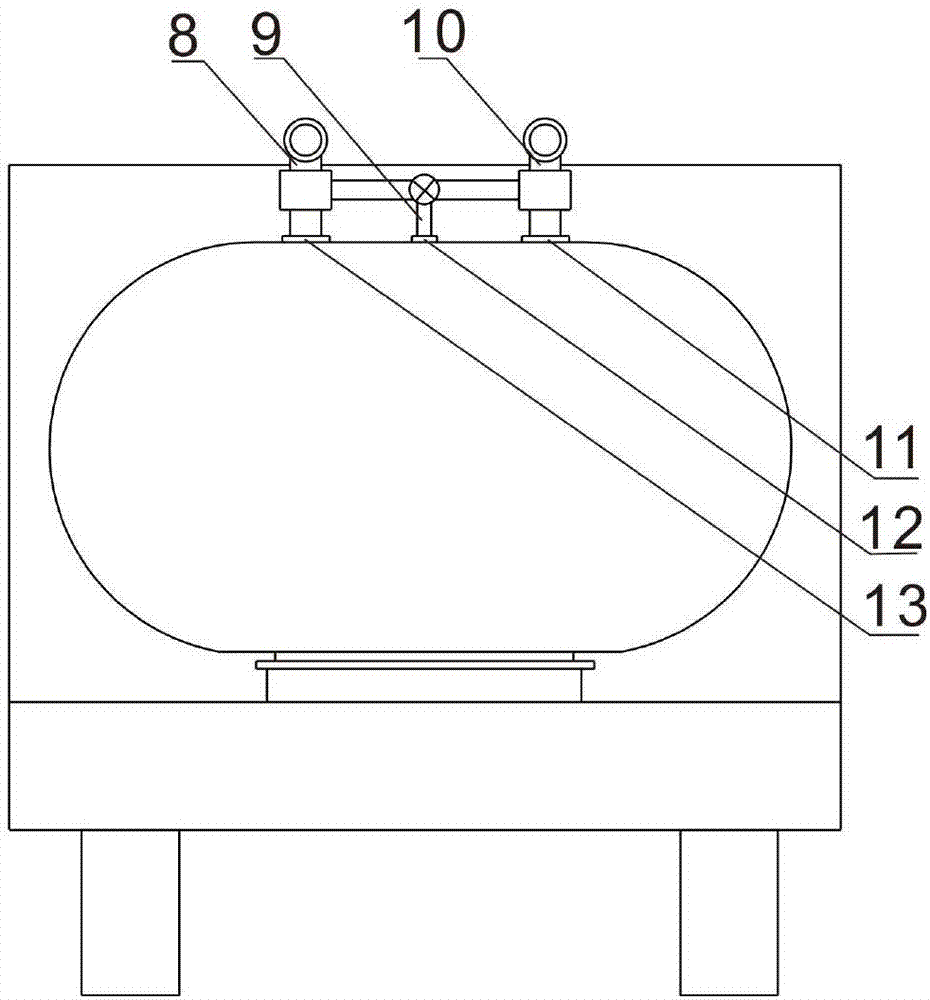

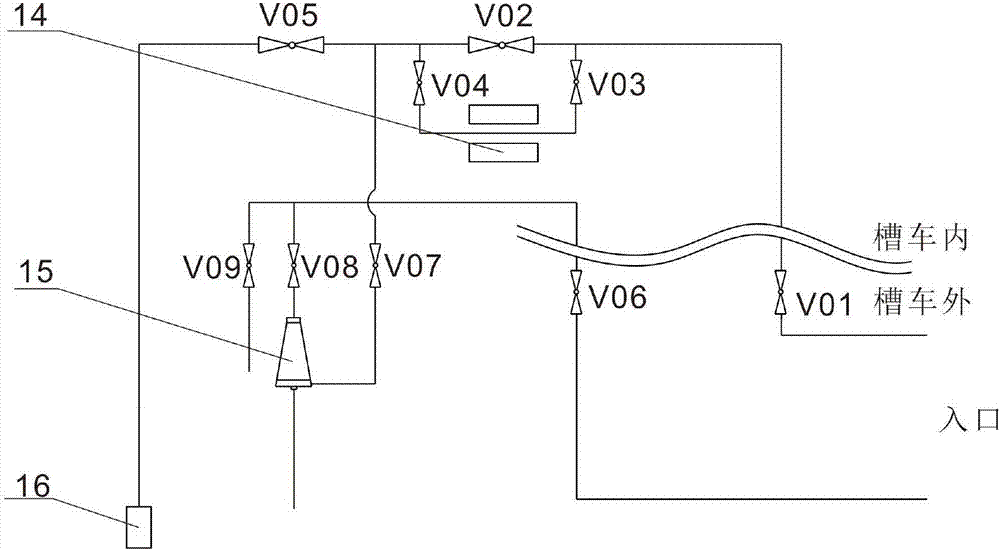

[0029] In the embodiment of the present invention, such as Figure 1~4 As shown, a spent fuel waste resin transfer tanker is provided, including a headstock 1, a tank body 4, a vehicle-mounted pressure water tank 2, a vehicle-mounted pressure gas tank 5, and pipe fittings provided with several sealing valves. Tank body 4 is connected with headstock, in order to be more convenient when turning, the present invention preferably adopts saddle to connect tank body 4 and headstock 1 together. The lower part of the tank body 4 is provided with a bracket 6 and a wheel set 7 . Manhole 3, material hole 13 and water hole 11 are arranged on the tank body, water removal pump 14 and jet device 15 are arranged in the tank body, and pipe fittings are connected with water removal pump 14 and jet device 15 by material hole 13 and water hole 11. The pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com