A tapered lock seal for specimens used in axial corrosion tests

A technology for sealing devices and corrosion tests, which is applied to measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc. It can solve the inconvenience of sample loading, corrosion of test equipment, and inability to effectively solve the problem of sealing and corrosive liquid leakage, etc. Problems, achieve good corrosive liquid leakage, easy loading and unloading, and prevent corrosive liquid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

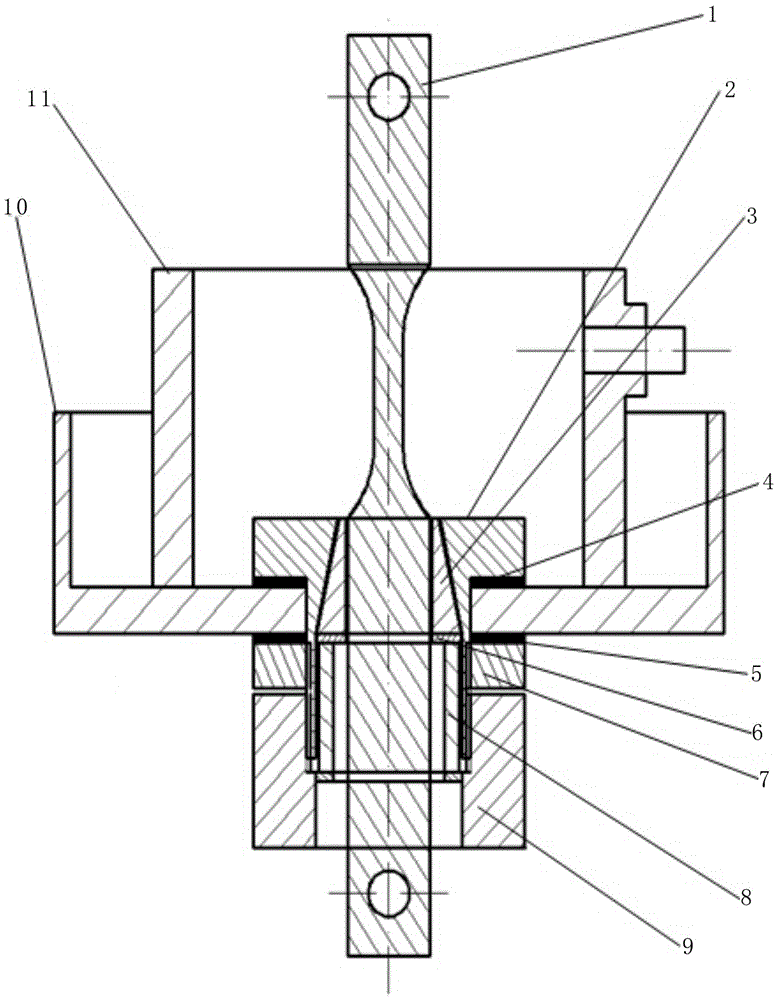

[0027] The tapered locking sealing device of the present invention includes an inner container 2, a rubber plug 3, a first gasket 4, a second gasket 5, a gasket 6, a fastening nut 7, a top sleeve 8, a locking nut 9, and a sample The length of 1 is divided into a fixed section, a stretched section and a clamping section, the lengths of the fixed section and the stretched section are basically equal, and the length of the clamping section is greater than the length of the fixed section or the length of the stretched section The length, the shape and structure of the fixed section and the clamping section are the same and set as the dimension Dmm, and the sample 1 is made according to the national standard.

[0028] The conical sealing device of the present invention borrows the overflow box 10 and the corrosion box 11, and the corrosion box 11 is welded in the overflow box 10.

[0029] Because the taper lock sealing device of the present invention is always in the immersion of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com