High-temperature brazing filler metal preparation method and brazing process for silicon carbide ceramic and composite materials thereof

A technology of silicon carbide ceramics and composite materials, which is applied in the direction of manufacturing tools, welding/cutting media/materials, welding media, etc., can solve problems such as poor machinability, imperfect silicon carbide connection technology, and restrictions on the practical application of silicon carbide. Strong practical value, solve the effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

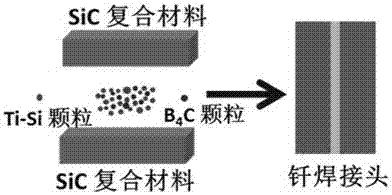

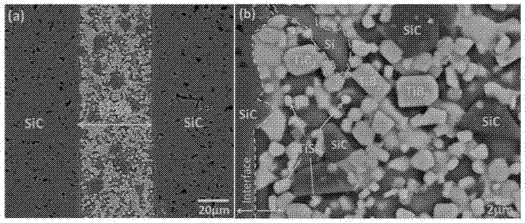

[0034] Example 1: Preparation of high temperature composite brazing filler metal

[0035] The preparation method of the high-temperature brazing filler metal used for silicon carbide ceramics and their composite materials in the present embodiment is as follows:

[0036] 1. Mix the proportion of high-purity titanium and high-purity silicon and use non-consumable arc smelting, then cool with the furnace, solidify into a brazing alloy block, turn the block over to continue melting, repeat five times; high-purity titanium and The high-purity silicon is constituted by mass percentage as follows: high-purity titanium 24wt.%, high-purity silicon 76wt.%.

[0037] 2. The brazing alloy block obtained in step 1 is mechanically smashed, and then the smashed alloy is ground into powder with an average particle size of less than 1 mm with a grinder, and then ball milled into a brazing filler metal powder with an average particle size of 10 μm.

[0038] 3. Combine the solder powder obtaine...

Embodiment 2

[0039] Example 2: Preparation of high temperature composite brazing filler metal

[0040] The preparation method of the high-temperature brazing filler metal used for silicon carbide ceramics and their composite materials in the present embodiment is as follows:

[0041] 1. Mix the proportion of high-purity titanium and high-purity silicon and perform vacuum induction melting (the vacuum degree is 10 -2 Below Pa, the smelting temperature is 1700°C, and the holding time is 20min), which is cooled with the furnace and solidified into a solder alloy block; the high-purity titanium and high-purity silicon are composed by mass percentage: high-purity titanium 22wt.%, high-purity silicon 78wt.% .

[0042] 2. The brazing filler metal alloy block obtained in step 1 is mechanically smashed, and then the smashed alloy is ground into powder with an average particle size of less than 1 mm with a grinder, and then ball milled into a brazing filler metal powder with an average particle siz...

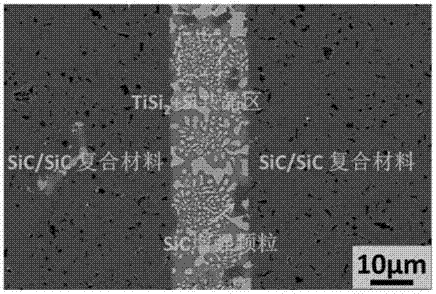

Embodiment 3

[0044] Example 3: Preparation of high temperature composite brazing filler metal

[0045] The preparation method of the high-temperature brazing filler metal used for silicon carbide ceramics and their composite materials in the present embodiment is as follows:

[0046] 1. Mix the proportion of high-purity titanium and high-purity silicon and use non-consumable arc smelting, cool with the furnace, solidify into a brazing alloy block, turn the block over to continue smelting, repeat five times; high-purity titanium and The high-purity silicon is constituted by mass percentage as follows: high-purity titanium 20wt.%, high-purity silicon 80wt.%.

[0047] 2. The brazing alloy block obtained in step 1 is mechanically smashed, and then the smashed alloy is ground into powder with an average particle size of less than 1 mm with a grinder, and then ball milled into a brazing filler metal powder with an average particle size of 10 μm.

[0048]3. Mix the brazing filler metal powder ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com