Method for continuously monitoring corrosivity of field environment by utilizing corrosion sensor

A corrosion sensor and corrosive technology, which is applied in weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., can solve problems that affect test results, short circuits, and data that cannot be scientifically and effectively analyzed, so as to promote sharing and long-term accumulation. Long service life, true representation of the effect of environmental corrosiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

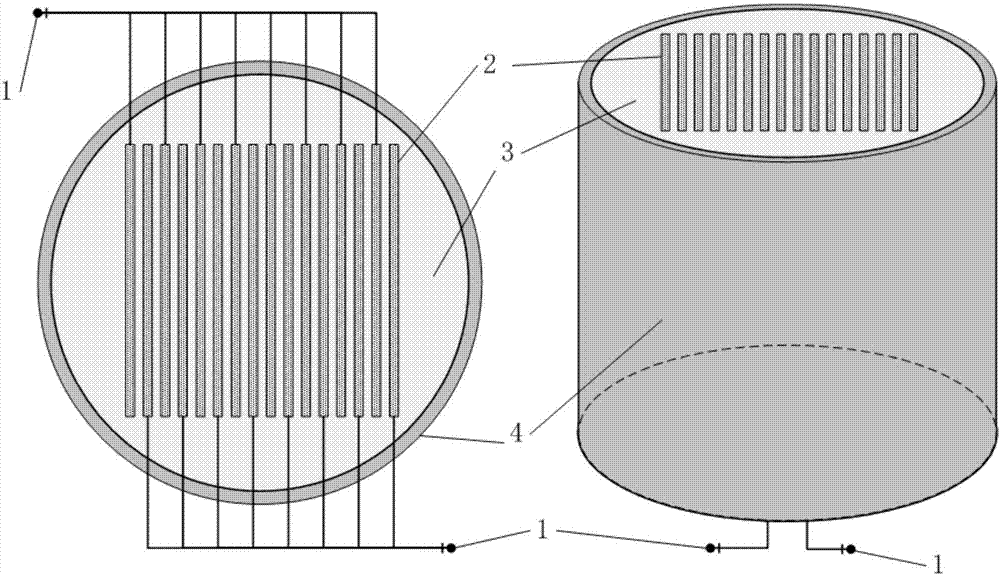

[0034] Select Q235 carbon steel material, prepare 16 pieces of metal test pieces with a size of 50mm×20mm×1mm by wire cutting method, use sandpaper to polish all the test pieces and degrease with acetone, weld copper wires on the width side of the test pieces and Divide into two groups and connect them in parallel to form two groups of electrode pairs. The carbon steel test pieces in the electrode pairs are arranged alternately in a cylindrical casing made of polytetrafluoroethylene, and sealed with epoxy resin. The epoxy resin is completely sealed. After curing, the electrode exposed at one end of the casing is polished and degreased again, and the corrosion sensor of the present invention is manufactured.

[0035] The corrosion sensor manufactured by the present invention is placed in the NaCl solution of 3.5% by weight, and the two wires of the corrosion sensor are respectively connected to the working electrode and the auxiliary electrode of the commercially available PS268...

Embodiment 2

[0040] The corrosion sensor manufactured in Example 1 was placed in the atmospheric environment of Beijing, and the two wires of the corrosion sensor were respectively connected to the working electrode and the auxiliary electrode of the commercially available PS268A potentiostat. The following automatic tests are realized through a simple program on the computer side:

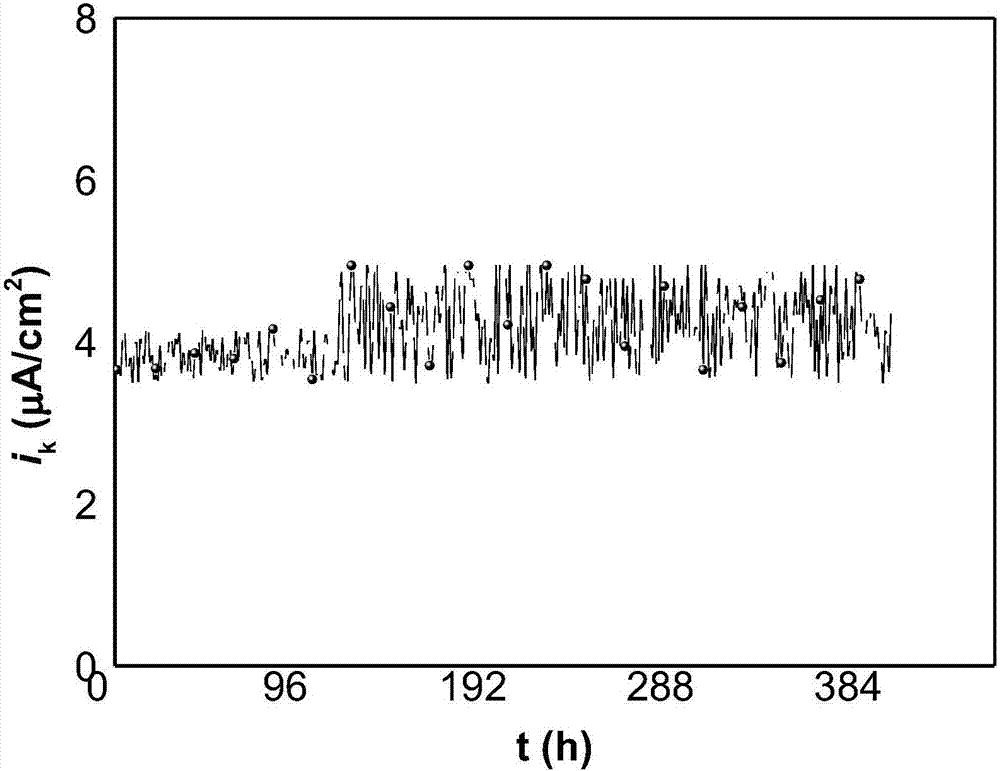

[0041] Test 1 is, first, control the potentiostat to input a 20mV DC voltage signal, and automatically collect the output current signal i in the loop through the device a After the test is completed, wait for 15 minutes and then control the potentiostat to input a -20mV DC voltage signal again, and automatically collect the output current signal i in the loop through the device c , collected i a and i c The value is calculated by a simple program on the computer according to the formula "i k =(i a × i c ) / (i c -i a )” to calculate the parameter i that characterizes the corrosivity of the environment k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com