A Honeycomb Gas Cooler for Carbon Dioxide Heat Pump

A gas cooler, carbon dioxide technology, applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of manufacturing difficulties, bulky gas coolers, low heat exchange efficiency, etc., and achieve heat exchange speed. Fast, reduced pressure drop, good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

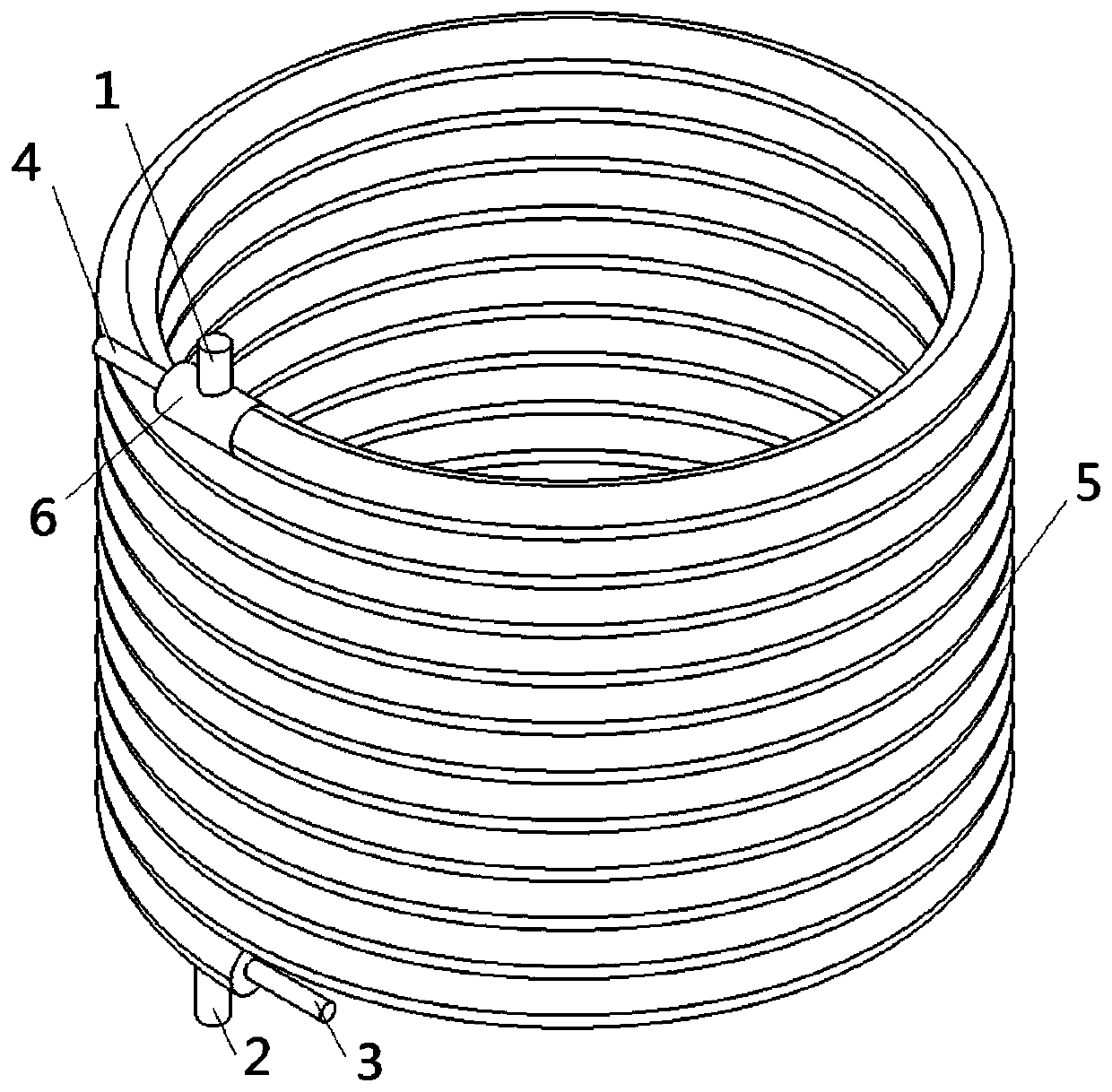

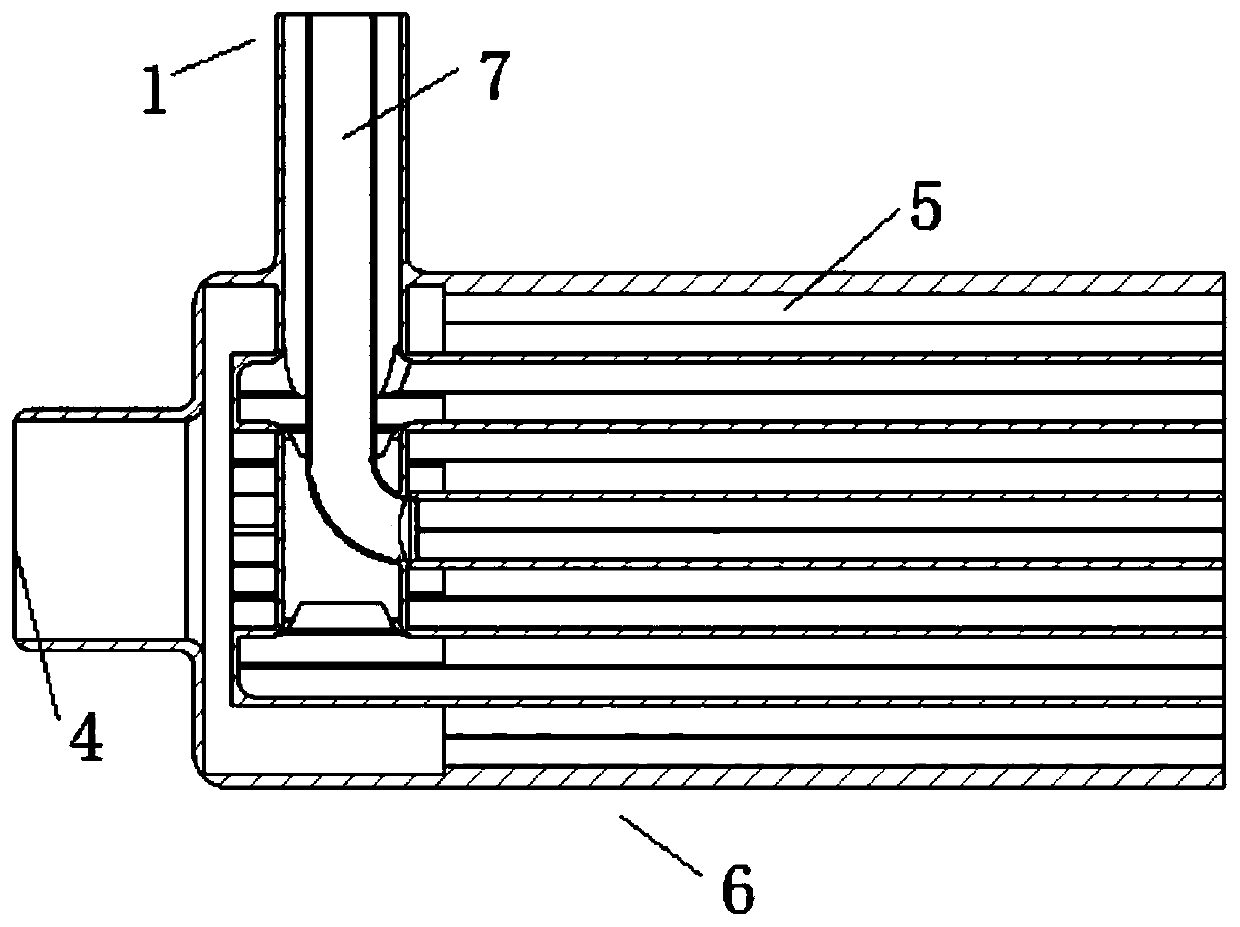

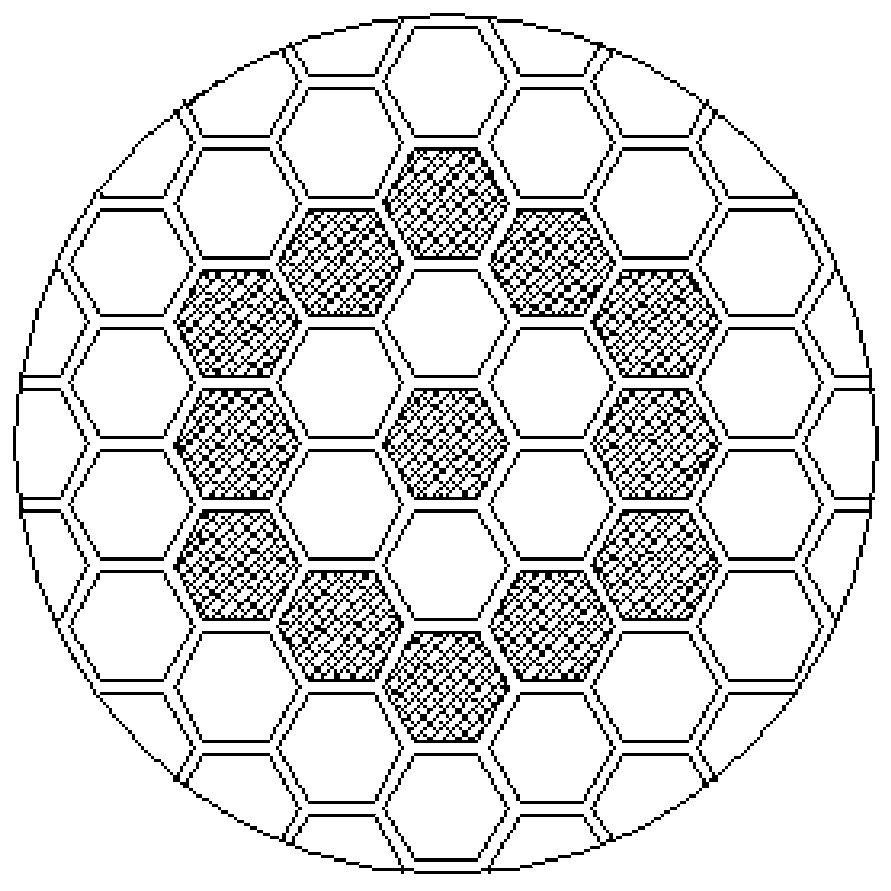

[0025] see figure 1 A honeycomb gas cooler for a carbon dioxide heat pump provided by the present invention includes a honeycomb heat exchange unit body 5 in cross section and a carbon dioxide sleeve 7 sleeved at the center of the heat exchange unit body 5; wherein One end of the heat exchange monomer body 5 is the coolant inlet 3 , the other end is the coolant outlet 4 , one end of the carbon dioxide sleeve 7 is the carbon dioxide gas inlet 1 , and the other end is the carbon dioxide gas outlet 2 .

[0026] figure 1 It is the appearance diagram of the honeycomb heat exchanger. Its external shape is similar to that of a sleeve-and-tube heat exchanger, which is arranged in a spiral tube shape. This structure makes the gas cooler more compact and efficient. During the heat exchange process, carbon dioxide enters the heat exchanger from the carbon dioxide gas inlet 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com