Knife-shaped gate valve body and manufacturing process thereof

A technology of knife gate valve and valve body, which is applied in the directions of casting mold, core, sliding valve, etc., can solve the problems of poor sealing performance, reduced sealing effect, and reduced sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

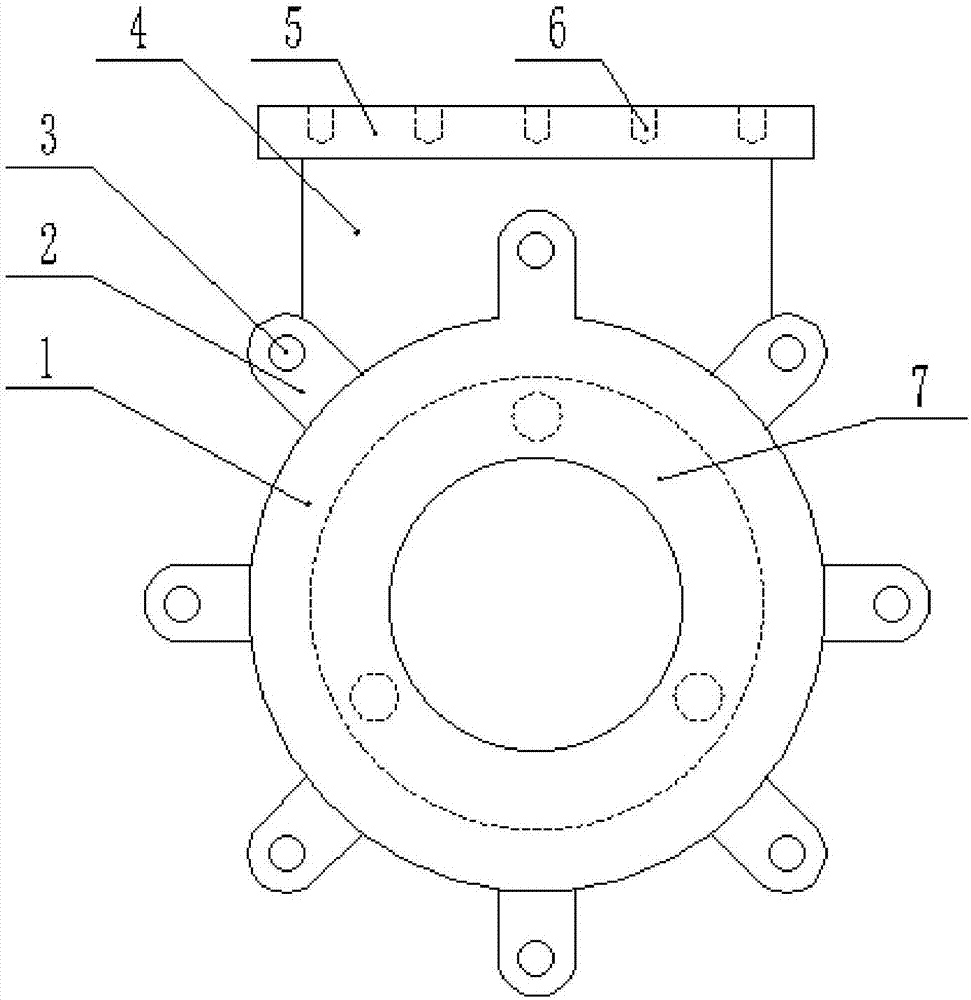

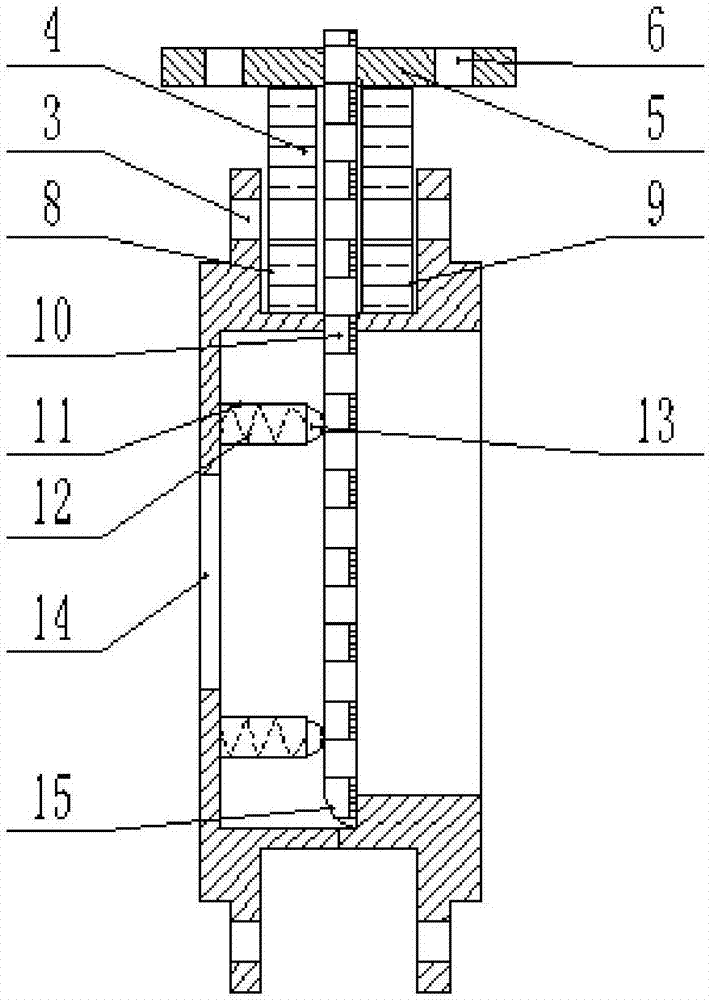

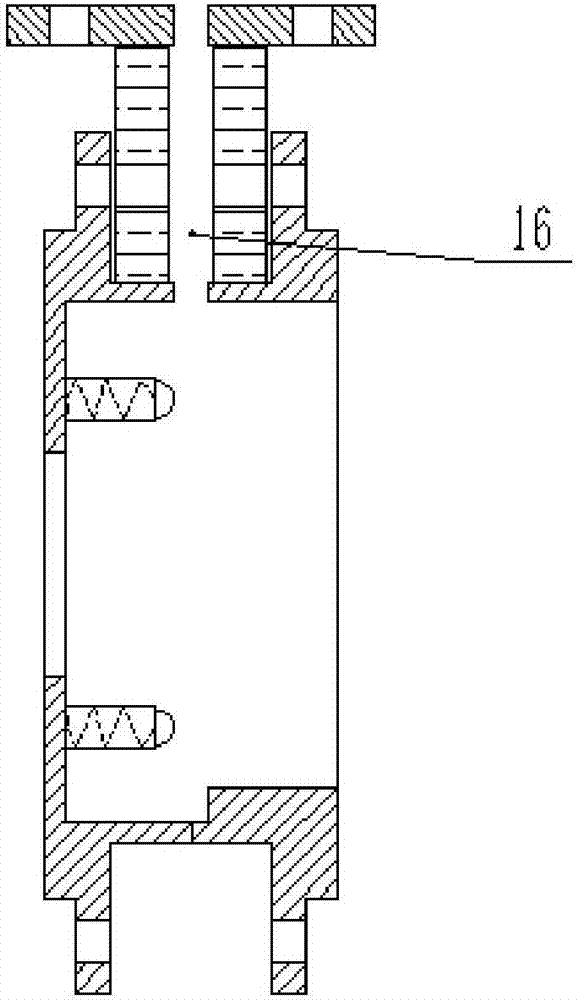

[0063] Combine below Figure 1-3 The structure of the knife-type gate valve body of this embodiment is described in detail: a knife-type gate valve body includes a casing 1, and the casing 1 is bonded by a left valve body 8 and a right valve body 9 with an annular hollow structure and the same outer diameter. Splicing structure, so as to form the cavity structure inside the shell 1, the same number of connecting blocks 2 are arranged at equal intervals along the respective circumferential directions on the sides of the left valve body 8 and the right valve body 9 And the positions are one-to-one correspondence, the connecting block 2 is welded and fixed, and the two connecting blocks 2 on the left valve body 8 and the right valve body 9 at the same corresponding position form a groove structure, and each connecting block 2 has a mounting hole 3 inside ;

[0064] The opening of the left valve body 8 away from the right valve body 9 side is used as the water inlet 14, and the e...

Embodiment 2

[0077] Combine below Figure 1-3 The structure of the knife-type gate valve body of this embodiment is described in detail: a knife-type gate valve body includes a casing 1, and the casing 1 is bonded by a left valve body 8 and a right valve body 9 with an annular hollow structure and the same outer diameter. Splicing structure, so as to form the cavity structure inside the shell 1, the same number of connecting blocks 2 are arranged at equal intervals along the respective circumferential directions on the sides of the left valve body 8 and the right valve body 9 And the positions are one-to-one correspondence, the connecting block 2 is welded and fixed, and the two connecting blocks 2 on the left valve body 8 and the right valve body 9 at the same corresponding position form a groove structure, and each connecting block 2 has a mounting hole 3 inside ;

[0078] The opening of the left valve body 8 away from the right valve body 9 side is used as the water inlet 14, and the e...

Embodiment 3

[0091] This embodiment provides a production process for a knife-type gate valve body, and the specific operation steps are as follows:

[0092] (1) Smelting raw materials:

[0093] a. Add the raw material of the knife-type gate valve body into the furnace, raise the temperature in the furnace to 1550°C, and the raw material is smelted to form an alloy solution;

[0094] b. Cool the alloy solution obtained in the previous step. When cooling, combine water cooling and air cooling. First use water cooling to cool the alloy solution to 455°C at a cooling rate of 26°C / s to form an alloy, then air cool to 355°C, and then use water cooling Water-cool the alloy to room temperature at a cooling rate of 12°C / s;

[0095] c. Heating, put the alloy cooled in the previous step into the furnace for secondary melting, raise the temperature in the furnace to 1830°C, and the alloy is secondary smelted to form an alloy solution;

[0096] d. Hot ladle, pour the alloy solution in the furnace in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com